Question: Part 1 : Create a spreadsheet template that calculates the following from inputs of cutting speed, feed per tooth, number of teeth ( 1 if

Part : Create a spreadsheet template that calculates the following from inputs of cutting speed, feed per tooth, number of teeth if turning tool milling or part turning diameter, and radial andor axial depth of cut points:

RPM

Feed rate

MRR include inputs for radial and axial DOC

HP at tool

HP of spindlemotor assume efficiency

Time to perform turning operations

Part : Speeds, Feeds, Time, and Power points:

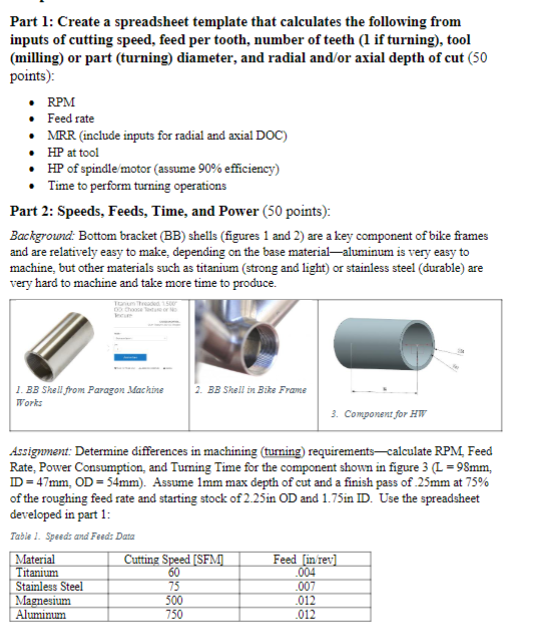

Background: Bottom bracket BB shells figures and are a key component of bike frames and are relatively easy to make, depending on the base materialaluminum is very easy to machine, but other materials such as titanium strong and light or stainless steel durable are very hard to machine and take more time to produce.

Assignment: Determine differences in machining turning requirementscalculate RPM Feed Rate, Power Consumption, and Tuming Time for the component shown in figure mathrmLmathrm~mmmathrmIDmathrm~mmmathrmODmathrm~mm Assume mm max depth of cut and a finish pass of mm at of the roughing feed rate and starting stock of in OD and in ID Use the spreadsheet developed in part :

Tabie Spuds and Fuds Data

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock