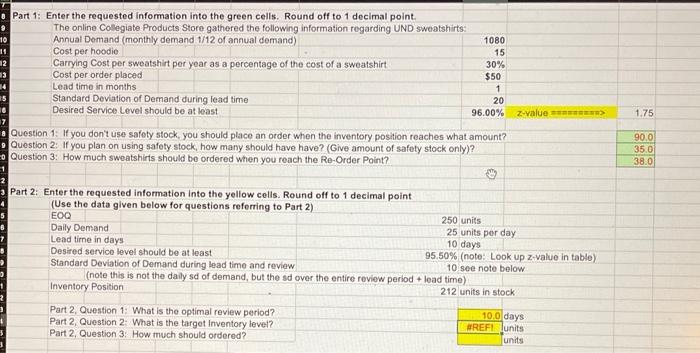

Question: Part 1: Enter the requested information into the green cells. Round off to 1 decimal point. The online Collegiate Products Store gathered the following information

Part 1: Enter the requested information into the green cells. Round off to 1 decimal point. The online Collegiate Products Store gathered the following information regarding UND sweatshirts: Annual Domand (monthly demand 1/12 of annual demand) Cost per hoodie. Carrying Cost per sweatshirt per year as a percentage of the cost of a sweatshirt Cost per order placed Lead time in months Standard Deviation of Demand during lead time Desired Service Level should be at least Question 1: If you don't use safety stock, you should place an order when the inventory position reaches what amount? Question 2: If you plan on using safety stock, how many should have have? (Give amount of safety stock only)? Question 3: How much sweatshirts should bo ordered when you reach the Re-Order Point? Part 2: Enter the requested information into the yellow cells. Round off to 1 decimal point (Use the data given below for questions referring to Part 2) EOQ Daily Demand 250 units Lead time in days 25 units per day Desired service level should be at least 10 days Standard Deviation of Demand during lead time and review 95.50\% (note: Look up z-value in table) (note this is not the dally sd of demand, but the sd over the entire roview period + lead time) Inventory Position 212 units in stock Part 2, Question 1: What is the optimal review period? Part 2, Question 2: What is the target Inventory level? Part 2, Question 3: How much should ordered? \begin{tabular}{|r|} \hline 10.0 days \\ \hline UREFI \\ \hline \end{tabular}

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts