Question: part 1 is asking for two DIFFERENT SYSTEMS. They are NOT apart of the same system. One of your friends, a chemist who does extracurricular

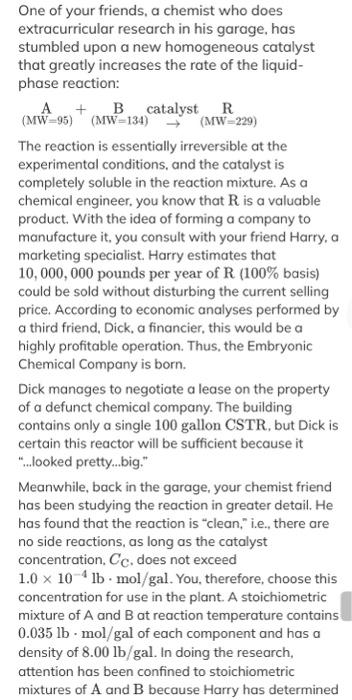

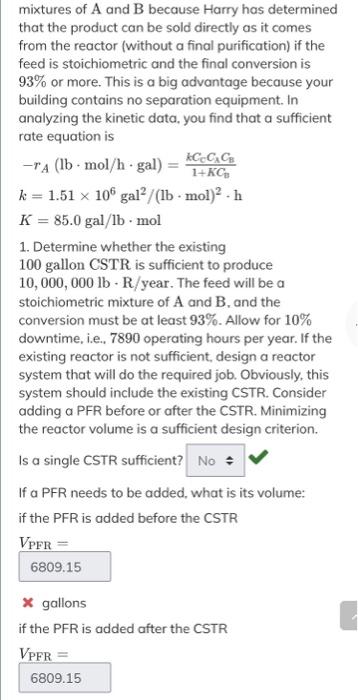

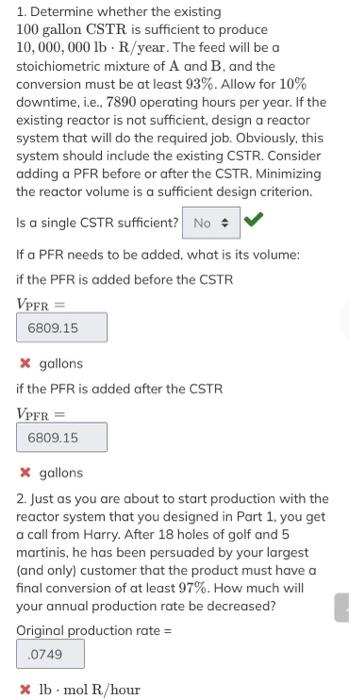

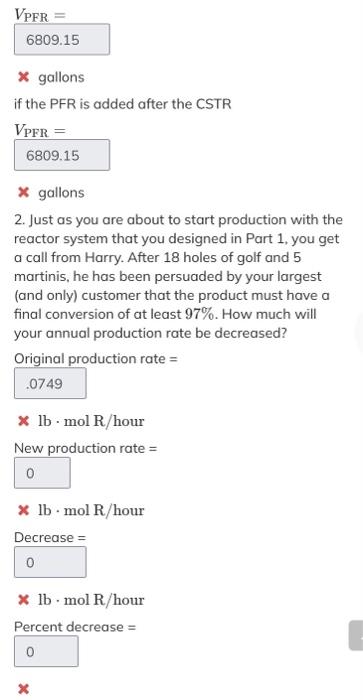

One of your friends, a chemist who does extracurricular research in his garage, has stumbled upon a new homogeneous catalyst that greatly increases the rate of the liquidphase reaction: (MW=95)A+(MW=134)Bcatalyst(MW=229)R The reaction is essentially irreversible at the experimental conditions, and the catalyst is completely soluble in the reaction mixture. As a chemical engineer. you know that R is a valuable product. With the idea of forming a company to manufacture it, you consult with your friend Harry, a marketing specialist. Harry estimates that 10,000,000 pounds per year of R ( 100% basis) could be sold without disturbing the current selling price. According to economic analyses performed by a third friend, Dick, a financier, this would be a highly profitable operation. Thus, the Embryonic Chemical Company is born. Dick manages to negotiate a lease on the property of a defunct chemical company. The building contains only a single 100 gallon CSTR, but Dick is certain this reactor will be sufficient because it "...looked pretty...big." Meanwhile, back in the garage, your chemist friend has been studying the reaction in greater detail. He has found that the reaction is "clean," i.e., there are no side reactions, as long as the catalyst concentration, CC, does not exceed 1.0104lbmol/gal. You, therefore, choose this concentration for use in the plant. A stoichiometric mixture of A and B at reaction temperature contains 0.035lbmol/gal of each component and has a density of 8.00lb/gal. In doing the research, attention has been confined to stoichiometric mixtures of A and B because Harry has determined mixtures of A and B because Harry has determined that the product can be sold directly as it comes from the reactor (without a final purification) if the feed is stoichiometric and the final conversion is 93% or more. This is a big advantage because your building contains no separation equipment. In analyzing the kinetic data, you find that a sufficient rate equation is rA(lbmol/hgal)=1+KCBkCCCACBk=1.51106gal2/(lbmol)2hK=85.0gal/lbmol 1. Determine whether the existing 100 gallon CSTR is sufficient to produce 10,000,000lbR/ year. The feed will be a stoichiometric mixture of A and B, and the conversion must be at least 93%. Allow for 10% downtime, i.e.. 7890 operating hours per year. If the existing reactor is not sufficient, design a reactor system that will do the required job. Obviously, this system should include the existing CSTR. Consider adding a PFR before or after the CSTR. Minimizing the reactor volume is a sufficient design criterion. Is a single CSTR sufficient? If a PFR needs to be added, what is its volume: if the PFR is added before the CSTR VPFR= x gallons if the PFR is added after the CSTR 100 gallon CSTR is sufficient to produce 10,000,000lbR/ year. The feed will be a stoichiometric mixture of A and B, and the conversion must be at least 93%. Allow for 10% downtime, i.e.. 7890 operating hours per year. If the existing reactor is not sufficient. design a reactor system that will do the required job. Obviously, this system should include the existing CSTR. Consider adding a PFR before or after the CSTR. Minimizing the reactor volume is a sufficient design criterion. Is a single CSTR sufficient? If a PFR needs to be added, what is its volume: if the PFR is added before the CSTR VPFR= x gallons if the PFR is added after the CSTR VPFR= x gallons 2. Just as you are about to start production with the reactor system that you designed in Part 1 , you get a call from Harry. After 18 holes of golf and 5 martinis, he has been persuaded by your largest (and only) customer that the product must have a final conversion of at least 97%. How much will your annual production rate be decreased? Original production rate = xlbmolR/ hour x gallons if the PFR is added after the CSTR VPFR= x gallons 2. Just as you are about to start production with the reactor system that you designed in Part 1 , you get a call from Harry. After 18 holes of golf and 5 martinis, he has been persuaded by your largest (and only) customer that the product must have a final conversion of at least 97%. How much will your annual production rate be decreased? Original production rate = x lb.mol R/hour New production rate = x lb.mol R/hour Decrease = xlbmolR /hour Percent decrease =

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts