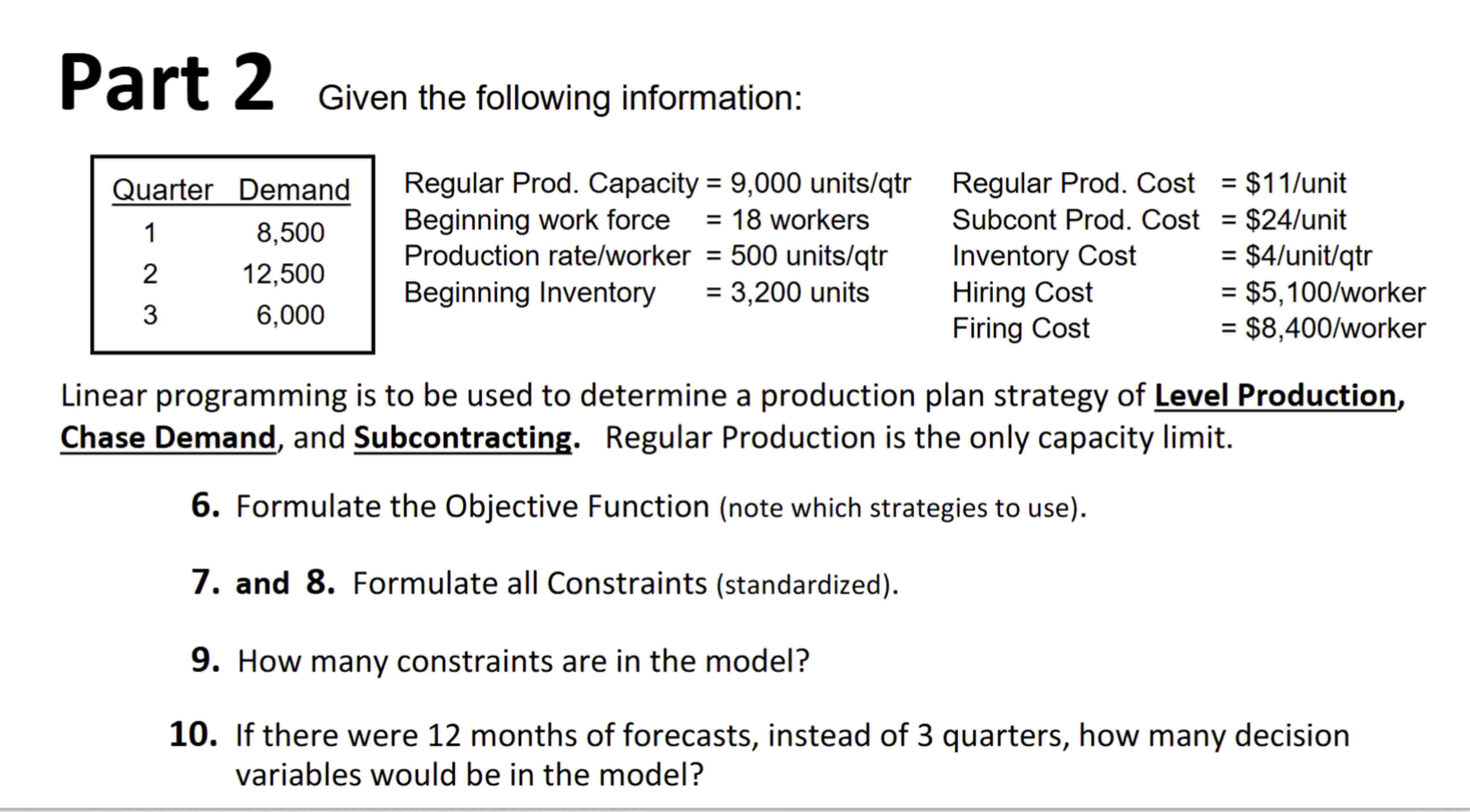

Question: Part 2 given the following information: Regular Prod. Capacity ( = 9 , 0 0 0 ) units / qtr Regular Prod. Cost

Part given the following information:

Regular Prod. Capacity unitsqtr

Regular Prod. Cost $unit

Beginning work force workers

Subcont Prod. Cost $unit

Production rateworker unitsqtr

Inventory Cost $unitqtr

Beginning Inventory units

Hiring Cost quad$ worker

Firing Cost quad$ worker

Linear programming is to be used to determine a production plan strategy of Level Production,

Chase Demand, and Subcontracting. Regular Production is the only capacity limit

Formulate the Objective Function note which strategies to use

and Formulate all Constraints standardized

How many constraints are in the model?

If there were months of forecasts, instead of quarters, how many decision variables would be in the model?

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock