Question: PART a and b please, thank you so much Question 4 (Total 30 marks). GIANT is a company that produces bicycles and sells them to

PART a and b please, thank you so much

PART a and b please, thank you so much

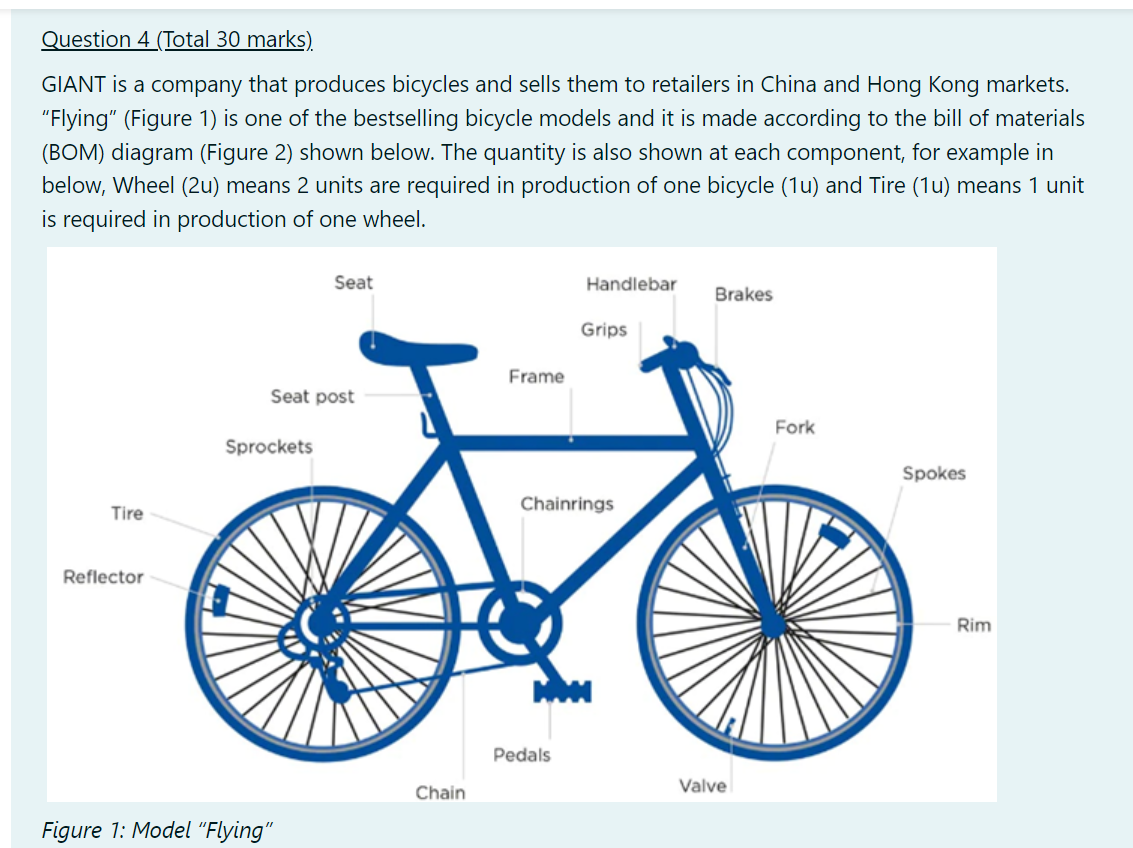

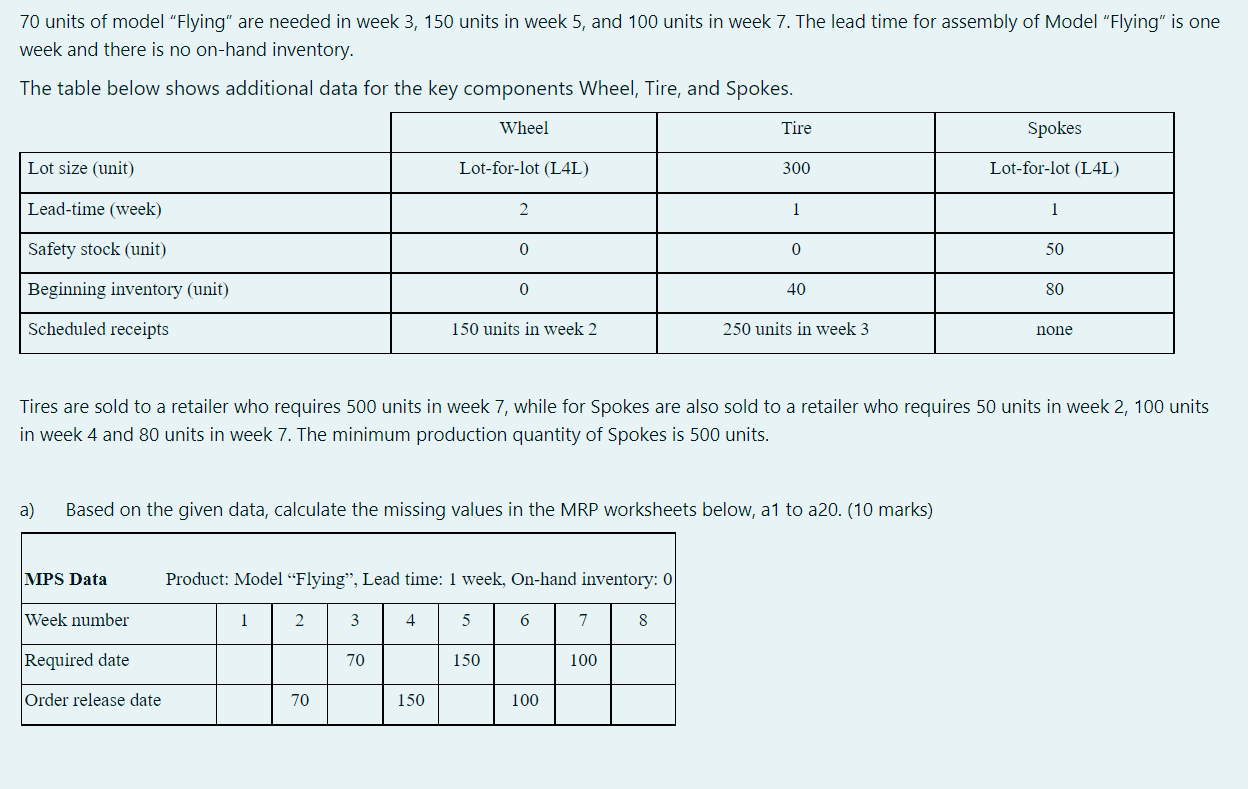

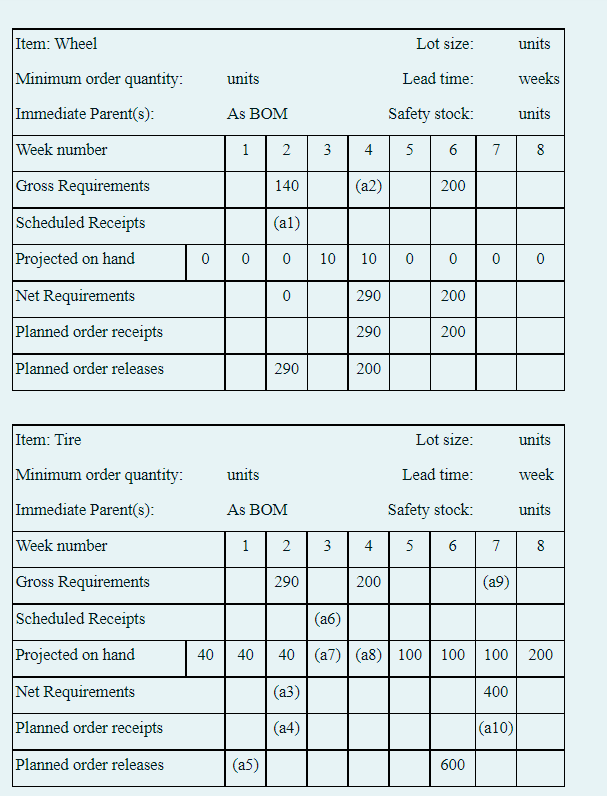

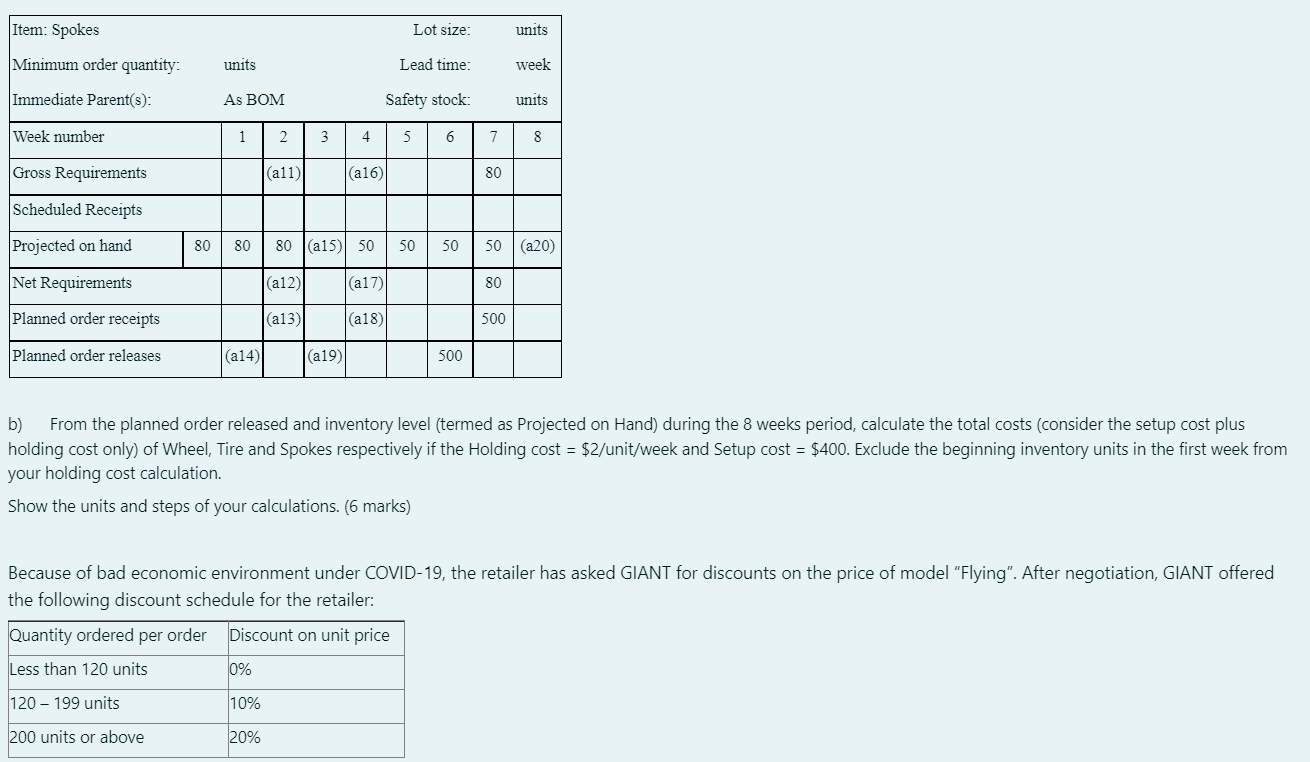

Question 4 (Total 30 marks). GIANT is a company that produces bicycles and sells them to retailers in China and Hong Kong markets. "Flying" (Figure 1) is one of the bestselling bicycle models and it is made according to the bill of materials (BOM) diagram (Figure 2) shown below. The quantity is also shown at each component, for example in below, Wheel (2u) means 2 units are required in production of one bicycle (1u) and Tire (1u) means 1 unit is required in production of one wheel. Seat Handlebar Brakes Grips Frame Seat post Fork Sprockets Spokes Tire Chainrings Reflector Rim Pedals Chain Valve Figure 1: Model "Flying" 70 units of model "Flying" are needed in week 3, 150 units in week 5, and 100 units in week 7. The lead time for assembly of Model "Flying" is one week and there is no on-hand inventory. The table below shows additional data for the key components Wheel, Tire, and Spokes. Wheel Tire Spokes Lot size (unit) Lot-for-lot (L4L) 300 Lot-for-lot (L4L) Lead-time (week) 1 1 Safety stock (unit) 0 0 50 Beginning inventory (unit) 0 40 80 Scheduled receipts 150 units in week 2 250 units in week 3 none Tires are sold to a retailer who requires 500 units in week 7, while for Spokes are also sold to a retailer who requires 50 units in week 2, 100 units in week 4 and 80 units in week 7. The minimum production quantity of Spokes is 500 units. a) Based on the given data, calculate the missing values in the MRP worksheets below, a1 to a 20. (10 marks) MPS Data Product: Model "Flying, Lead time: 1 week, On-hand inventory: 0 Week number 1 2. 3 4 5 6 7 8 Required date 70 150 100 Order release date 70 150 100 Lot size: units Item: Wheel Minimum order quantity: Immediate Parent(s); units Lead time: weeks As BOM Safety stock: units Week number 1 2 2 3 4 5 6 7 8 Gross Requirements 140 (22) 200 Scheduled Receipts (al) Projected on hand 0 0 0 10 10 0 0 0 0 Net Requirements 0 290 200 Planned order receipts 290 200 Planned order releases 290 200 Item: Tire Lot size: units units Lead time: week Minimum order quantity: Immediate Parent(s); As BOM Safety stock: units Week number 1 2 2 3 4 5 6 7 8 Gross Requirements 290 200 (9) Scheduled Receipts (ab) Projected on hand 40 40 40(27) (a8) 100 100 100 200 Net Requirements (a3) 400 Planned order receipts (a4) (210) Planned order releases (a5) 600 Item: Spokes Lot size: units Minimum order quantity: units Lead time: week Immediate Parent(s): As BOM Safety stock: units Week number 1 2 2 3 4 5 6 7 8 Gross Requirements (all) (116) 80 Scheduled Receipts Projected on hand 80 80 80 (a1550 50 50 50 (a20) Net Requirements (a12) (a17) 80 Planned order receipts (a13) (a18) 500 Planned order releases (a14) (219) 500 b) From the planned order released and inventory level (termed as Projected on Hand) during the 8 weeks period, calculate the total costs (consider the setup cost plus holding cost only) of Wheel, Tire and Spokes respectively if the Holding cost = $2/unit/week and Setup cost = $400. Exclude the beginning inventory units in the first week from your holding cost calculation. Show the units and steps of your calculations. (6 marks) Because of bad economic environment under COVID-19, the retailer has asked GIANT for discounts on the price of model "Flying". After negotiation, GIANT offered the following discount schedule for the retailer: Quantity ordered per order Discount on unit price Less than 120 units 0% 120 - 199 units 10% 200 units or above 20% Question 4 (Total 30 marks). GIANT is a company that produces bicycles and sells them to retailers in China and Hong Kong markets. "Flying" (Figure 1) is one of the bestselling bicycle models and it is made according to the bill of materials (BOM) diagram (Figure 2) shown below. The quantity is also shown at each component, for example in below, Wheel (2u) means 2 units are required in production of one bicycle (1u) and Tire (1u) means 1 unit is required in production of one wheel. Seat Handlebar Brakes Grips Frame Seat post Fork Sprockets Spokes Tire Chainrings Reflector Rim Pedals Chain Valve Figure 1: Model "Flying" 70 units of model "Flying" are needed in week 3, 150 units in week 5, and 100 units in week 7. The lead time for assembly of Model "Flying" is one week and there is no on-hand inventory. The table below shows additional data for the key components Wheel, Tire, and Spokes. Wheel Tire Spokes Lot size (unit) Lot-for-lot (L4L) 300 Lot-for-lot (L4L) Lead-time (week) 1 1 Safety stock (unit) 0 0 50 Beginning inventory (unit) 0 40 80 Scheduled receipts 150 units in week 2 250 units in week 3 none Tires are sold to a retailer who requires 500 units in week 7, while for Spokes are also sold to a retailer who requires 50 units in week 2, 100 units in week 4 and 80 units in week 7. The minimum production quantity of Spokes is 500 units. a) Based on the given data, calculate the missing values in the MRP worksheets below, a1 to a 20. (10 marks) MPS Data Product: Model "Flying, Lead time: 1 week, On-hand inventory: 0 Week number 1 2. 3 4 5 6 7 8 Required date 70 150 100 Order release date 70 150 100 Lot size: units Item: Wheel Minimum order quantity: Immediate Parent(s); units Lead time: weeks As BOM Safety stock: units Week number 1 2 2 3 4 5 6 7 8 Gross Requirements 140 (22) 200 Scheduled Receipts (al) Projected on hand 0 0 0 10 10 0 0 0 0 Net Requirements 0 290 200 Planned order receipts 290 200 Planned order releases 290 200 Item: Tire Lot size: units units Lead time: week Minimum order quantity: Immediate Parent(s); As BOM Safety stock: units Week number 1 2 2 3 4 5 6 7 8 Gross Requirements 290 200 (9) Scheduled Receipts (ab) Projected on hand 40 40 40(27) (a8) 100 100 100 200 Net Requirements (a3) 400 Planned order receipts (a4) (210) Planned order releases (a5) 600 Item: Spokes Lot size: units Minimum order quantity: units Lead time: week Immediate Parent(s): As BOM Safety stock: units Week number 1 2 2 3 4 5 6 7 8 Gross Requirements (all) (116) 80 Scheduled Receipts Projected on hand 80 80 80 (a1550 50 50 50 (a20) Net Requirements (a12) (a17) 80 Planned order receipts (a13) (a18) 500 Planned order releases (a14) (219) 500 b) From the planned order released and inventory level (termed as Projected on Hand) during the 8 weeks period, calculate the total costs (consider the setup cost plus holding cost only) of Wheel, Tire and Spokes respectively if the Holding cost = $2/unit/week and Setup cost = $400. Exclude the beginning inventory units in the first week from your holding cost calculation. Show the units and steps of your calculations. (6 marks) Because of bad economic environment under COVID-19, the retailer has asked GIANT for discounts on the price of model "Flying". After negotiation, GIANT offered the following discount schedule for the retailer: Quantity ordered per order Discount on unit price Less than 120 units 0% 120 - 199 units 10% 200 units or above 20%

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts