Question: Part A is produced on machine 1 and then machine 2. One unit of Part A is assembled with three units of Part B, which

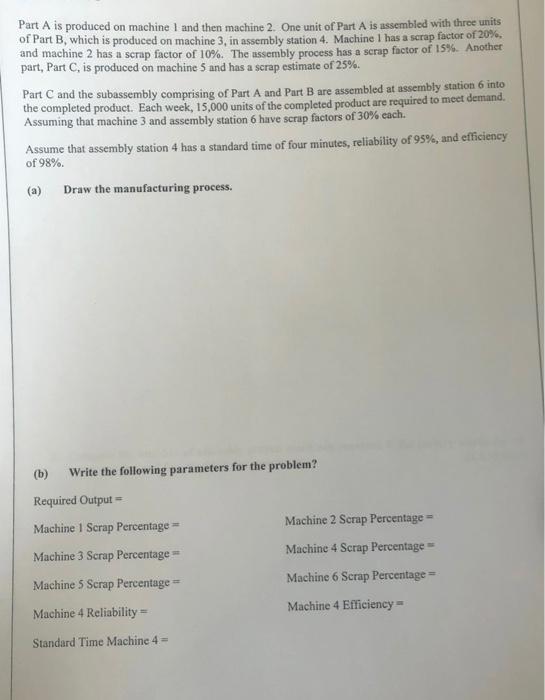

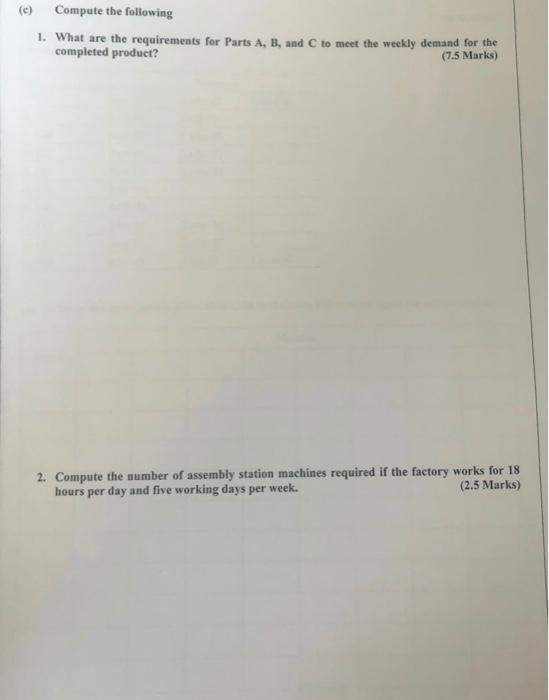

Part A is produced on machine 1 and then machine 2. One unit of Part A is assembled with three units of Part B, which is produced on machine 3, in assembly station 4 . Machine 1 has a serap factor of 20%, and machine 2 has a scrap factor of 10%. The assembly process has a scrap factor of 15%. Anothet part, Part C, is produced on machine 5 and has a scrap estimate of 25%. Part C and the subassembly comprising of Part A and Part B are assembled at assembly station 6 into the completed product. Each week, 15,000 units of the completed product are required to meet demand. Assuming that machine 3 and assembly station 6 have scrap factors of 30% each. Assume that assembly station 4 has a standard time of four minutes, reliability of 95%, and effieiency of 98%. (a) Draw the manufacturing process. (b) Write the following parameters for the problem? Required Output = Machine 1 Scrap Percentage = Machine 2 Scrap Percentage = Machine 3 Serap Percentage = Machine 4 Scrap Percentage = Machine 5 Scrap Percentage = Machine 6 Serap Percentage = Machine 4 Reliability = Machine 4 Efficiency = Standard Time Machine 4= (c) Compute the following 1. What are the requirements for Parts A,B, and C to meet the weekly demand for the completed product? (7.5 Marks) 2. Compute the number of assembly station machines required if the factory works for 18 hours per day and five working days per week. (2.5 Marks)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts