Question: Part A: Resolve a given business problem ( provided by instructor ) by applying an appropriate quantitative technique in EXCE L to achieve an optimal

Part A: Resolve a given business problem (provided by instructor) by applying an appropriate quantitative technique in EXCEL to achieve an optimal solution. (SLO 4.1-4.2)

Part B: Once completed, develop a recommendation for the firm. The report should respond to the following writing prompts:

- Explain all needs (e.g., financial, non-financial) of the hypothetical firm based on the given scenario.

- Discuss the firms cost options as given.

- Discuss the reasoning process applied to develop the math model as well as the technique used to achieve an optimal solution (e.g. application of the decision-making process steps).

- Make your recommendation.

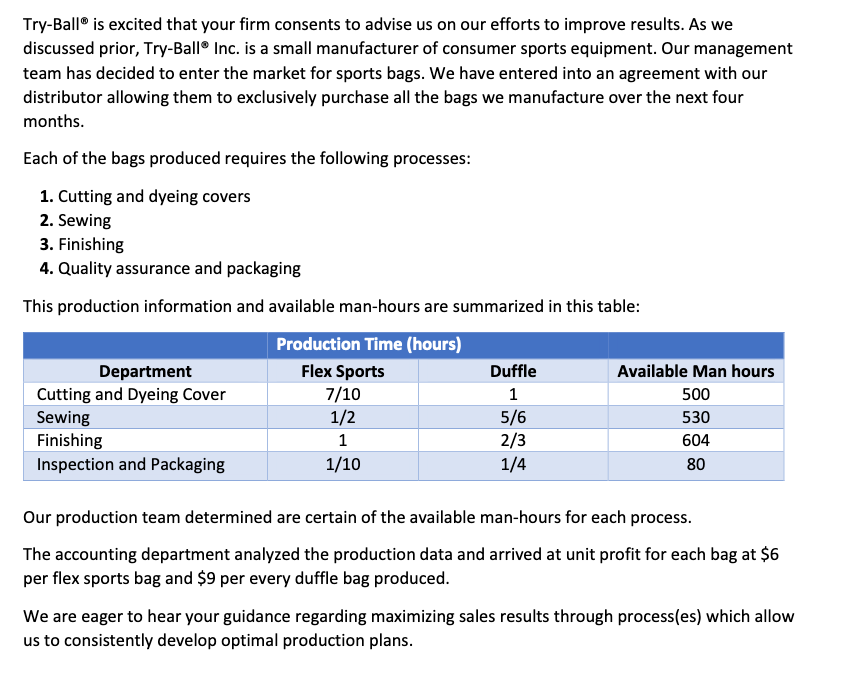

Try-Ball is excited that your firm consents to advise us on our efforts to improve results. As we discussed prior, Try-Ball Inc. is a small manufacturer of consumer sports equipment. Our management team has decided to enter the market for sports bags. We have entered into an agreement with our distributor allowing them to exclusively purchase all the bags we manufacture over the next four months. Each of the bags produced requires the following processes: 1. Cutting and dyeing covers 2. Sewing 3. Finishing 4. Quality assurance and packaging This production information and available man-hours are summarized in this table: Production Time (hours) Department Flex Sports Duffle Available Man hours Cutting and Dyeing Cover 7/10 1 500 Sewing 1/2 5/6 530 Finishing 1 2/3 604 Inspection and Packaging 1/10 1/4 80 Our production team determined are certain of the available man-hours for each process. The accounting department analyzed the production data and arrived at unit profit for each bag at $6 per flex sports bag and $9 per every duffle bag produced. We are eager to hear your guidance regarding maximizing sales results through process(es) which allow us to consistently develop optimal production plans. Try-Ball is excited that your firm consents to advise us on our efforts to improve results. As we discussed prior, Try-Ball Inc. is a small manufacturer of consumer sports equipment. Our management team has decided to enter the market for sports bags. We have entered into an agreement with our distributor allowing them to exclusively purchase all the bags we manufacture over the next four months. Each of the bags produced requires the following processes: 1. Cutting and dyeing covers 2. Sewing 3. Finishing 4. Quality assurance and packaging This production information and available man-hours are summarized in this table: Production Time (hours) Department Flex Sports Duffle Available Man hours Cutting and Dyeing Cover 7/10 1 500 Sewing 1/2 5/6 530 Finishing 1 2/3 604 Inspection and Packaging 1/10 1/4 80 Our production team determined are certain of the available man-hours for each process. The accounting department analyzed the production data and arrived at unit profit for each bag at $6 per flex sports bag and $9 per every duffle bag produced. We are eager to hear your guidance regarding maximizing sales results through process(es) which allow us to consistently develop optimal production plans

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts