Question: Part B: System Description: Consider a flow line layout manufacturing shop, where manufactured parts pass through three consecutive machines namely: Drill, Tapping machine and Painting

Part B:

System Description:

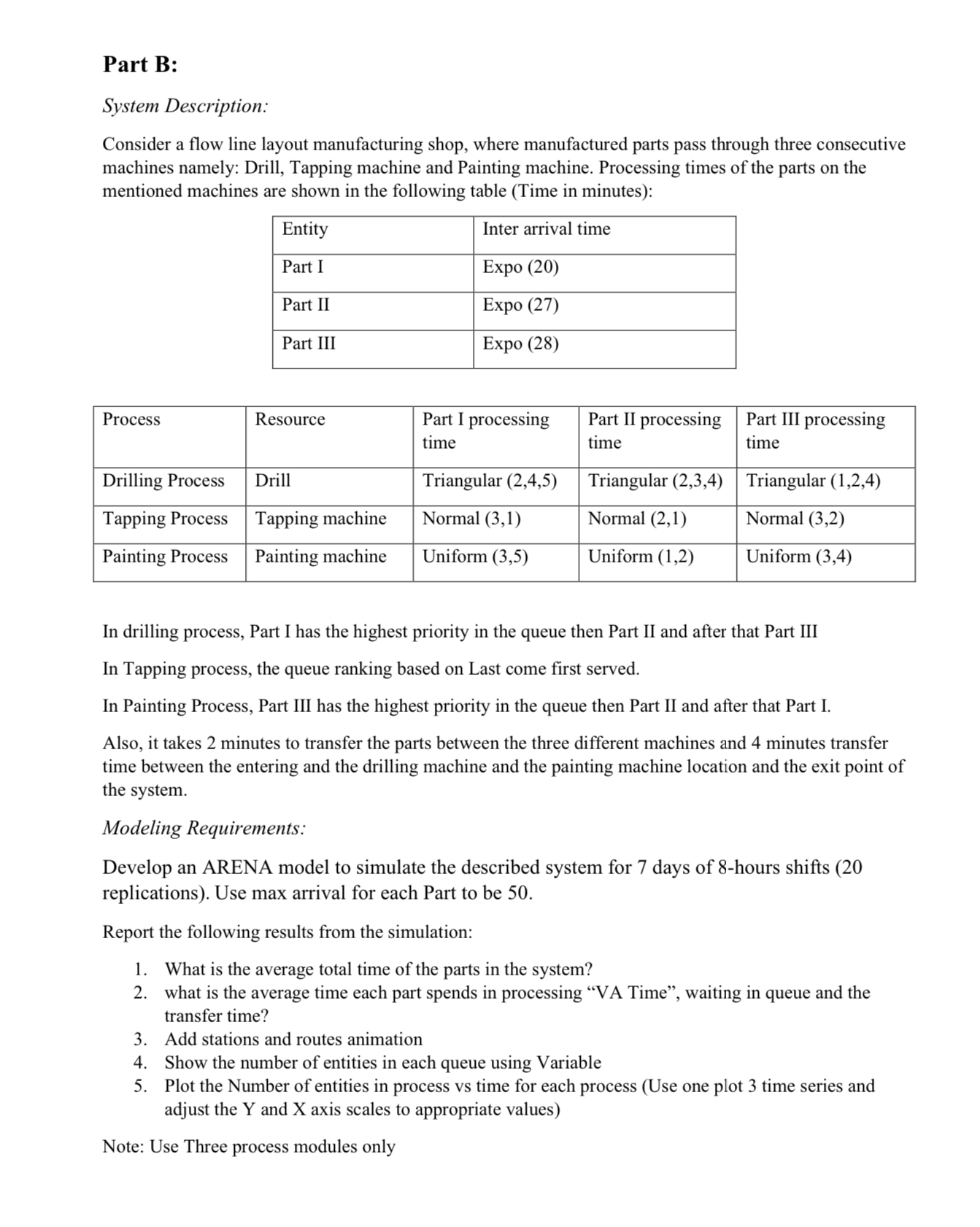

Consider a flow line layout manufacturing shop, where manufactured parts pass through three consecutive machines namely: Drill, Tapping machine and Painting machine. Processing times of the parts on the mentioned machines are shown in the following table Time in minutes:

tableEntityInter arrival timePart I,Expo Part IIExpo Part III,Expo

tableProcessResource,tablePart I processingtimetablePart II processingtimetablePart III processingtimeDrilling Process,Drill,Triangular Triangular Triangular Tapping Process,Tapping machine,Normal Normal Normal Painting Process,Painting machine,Uniform Uniform Uniform

In drilling process, Part I has the highest priority in the queue then Part II and after that Part III

In Tapping process, the queue ranking based on Last come first served.

In Painting Process, Part III has the highest priority in the queue then Part II and after that Part I.

Also, it takes minutes to transfer the parts between the three different machines and minutes transfer time between the entering and the drilling machine and the painting machine location and the exit point of the system.

Modeling Requirements:

Develop an ARENA model to simulate the described system for days of hours shifts replications Use max arrival for each Part to be

Report the following results from the simulation:

What is the average total time of the parts in the system?

what is the average time each part spends in processing VA Time", waiting in queue and the transfer time?

Add stations and routes animation

Show the number of entities in each queue using Variable

Plot the Number of entities in process vs time for each process Use one plot time series and adjust the Y and X axis scales to appropriate values

Note: Use Three process modules only

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock