Question: part C part E help Joe Henry's machine shop uses 2,500 brackets during the course of a year. These brackets are purchased from a supplier

part C

part E help

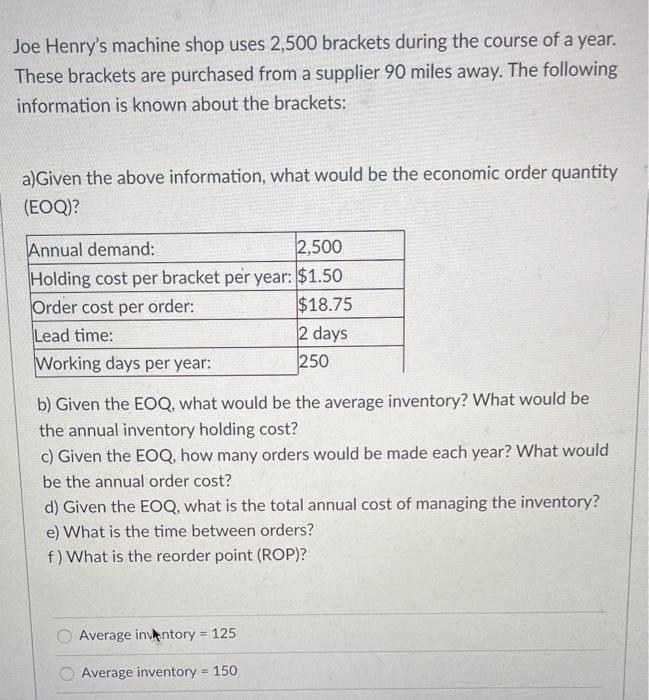

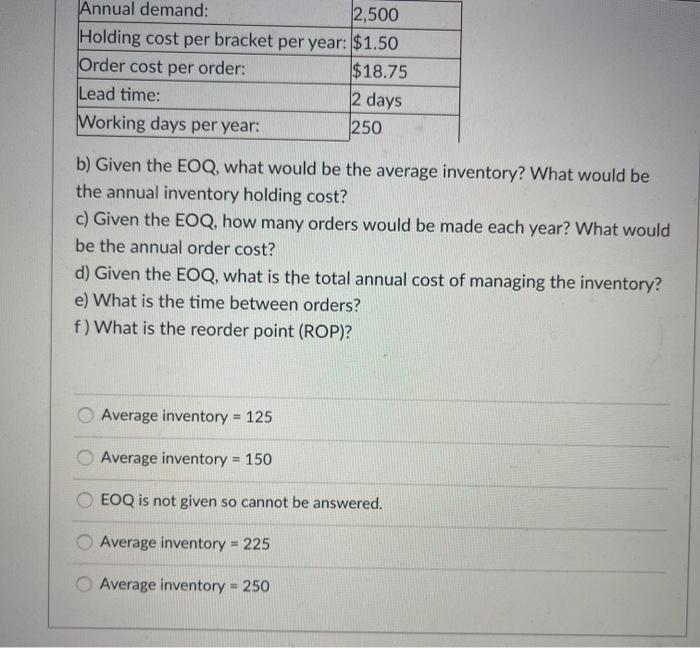

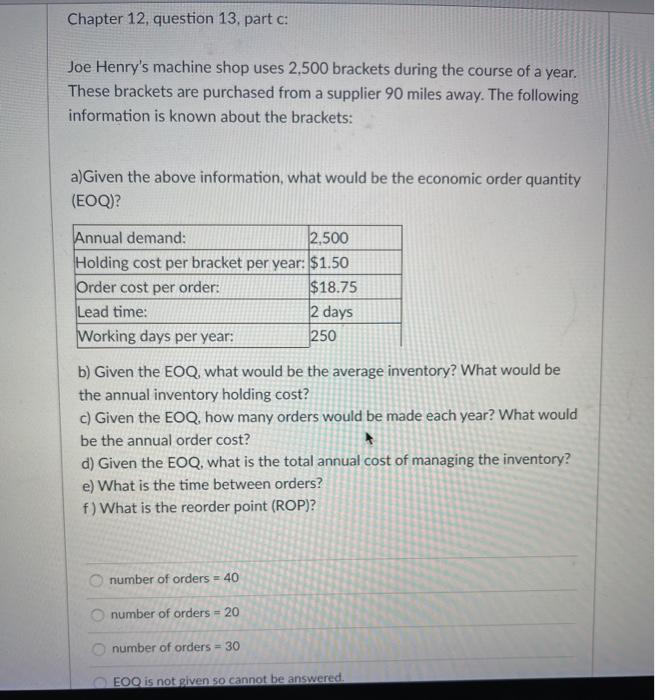

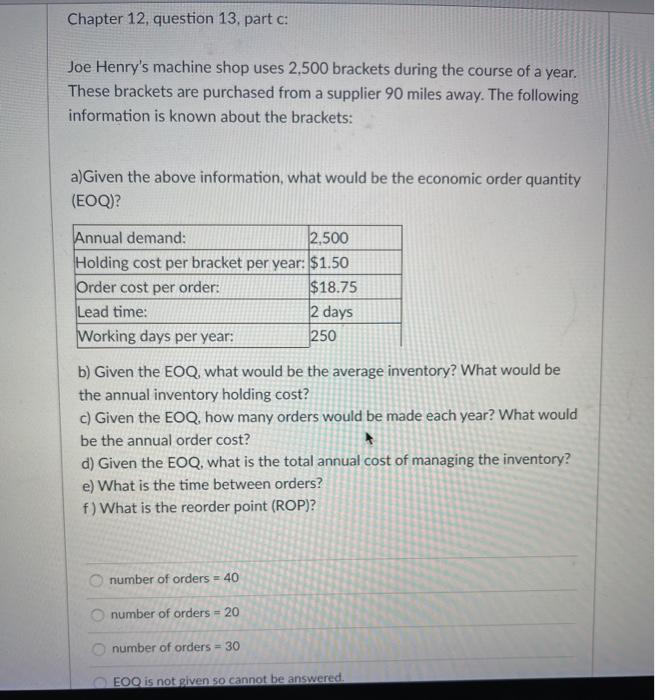

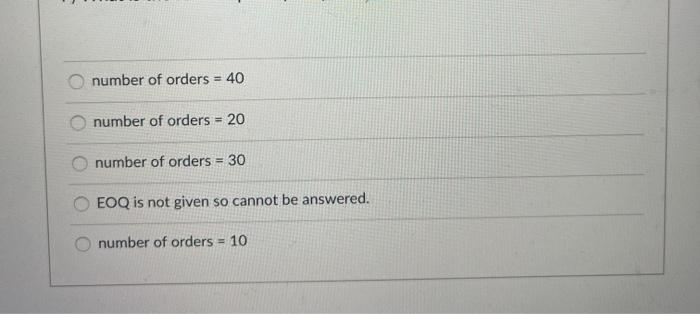

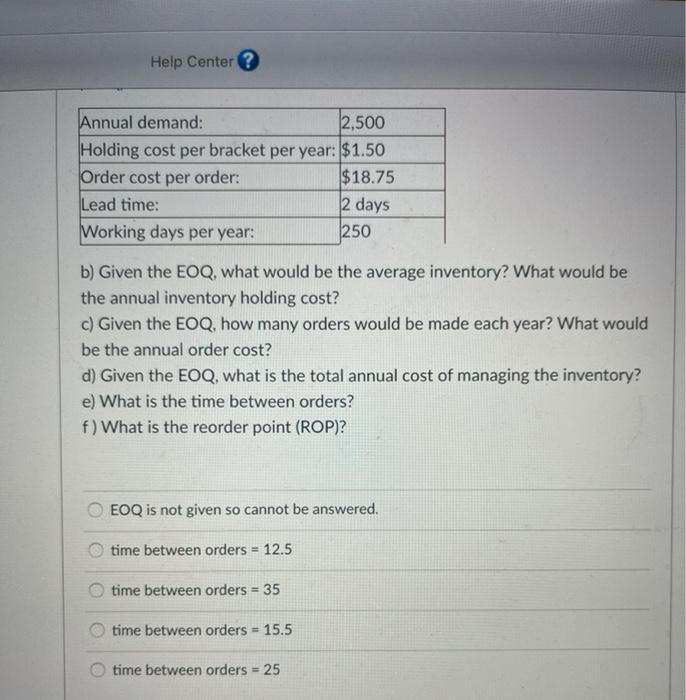

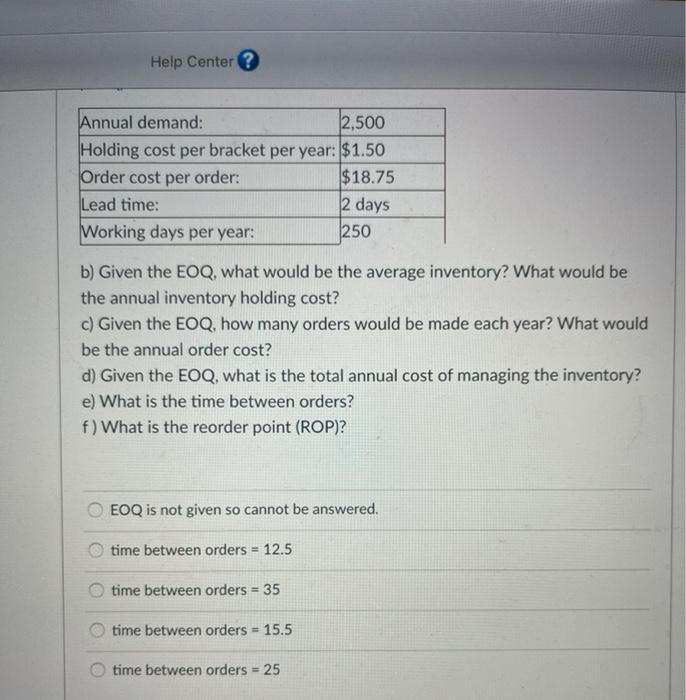

Joe Henry's machine shop uses 2,500 brackets during the course of a year. These brackets are purchased from a supplier 90 miles away. The following information is known about the brackets: a)Given the above information, what would be the economic order quantity (EOQ)? Annual demand: 2,500 Holding cost per bracket per year: $1.50 Order cost per order: $18.75 Lead time: 2 days Working days per year: 250 b) Given the EOQ, what would be the average inventory? What would be the annual inventory holding cost? c) Given the EOQ, how many orders would be made each year? What would be the annual order cost? d) Given the EOQ, what is the total annual cost of managing the inventory? e) What is the time between orders? f) What is the reorder point (ROP)? Average inventory = 125 Average inventory = 150 Annual demand: 2,500 Holding cost per bracket per year: $1.50 Order cost per order: $18.75 Lead time: 2 days Working days per year: 250 b) Given the EOQ, what would be the average inventory? What would be the annual inventory holding cost? c) Given the EOQ, how many orders would be made each year? What would be the annual order cost? d) Given the EOQ, what is the total annual cost of managing the inventory? e) What is the time between orders? f) What is the reorder point (ROP)? Average inventory = 125 Average inventory = 150 EOQ is not given so cannot be answered. Average inventory = 225 Average inventory = 250 Chapter 12, question 13. part c: Joe Henry's machine shop uses 2,500 brackets during the course of a year. These brackets are purchased from a supplier 90 miles away. The following information is known about the brackets: a)Given the above information, what would be the economic order quantity (EOQ)? Annual demand: 2,500 Holding cost per bracket per year: $1.50 Order cost per order: $18.75 Lead time: 2 days Working days per year: 250 b) Given the EOQ, what would be the average inventory? What would be the annual inventory holding cost? c) Given the EOQ, how many orders would be made each year? What would be the annual order cost? d) Given the EOQ, what is the total annual cost of managing the inventory? e) What is the time between orders? f) What is the reorder point (ROP)? number of orders = 40 number of orders = 20 number of orders = 30 EOO is not given so cannot be answered. number of orders = 40 number of orders = 20 number of orders = 30 EOQ is not given so cannot be answered. number of orders = 10 Help Center ? Annual demand: 2,500 Holding cost per bracket per year: $1.50 Order cost per order: $18.75 Lead time: 2 days Working days per year: 250 b) Given the EOQ, what would be the average inventory? What would be the annual inventory holding cost? c) Given the EOQ, how many orders would be made each year? What would be the annual order cost? d) Given the EOQ, what is the total annual cost of managing the inventory? e) What is the time between orders? f) What is the reorder point (ROP)? EOQ is not given so cannot be answered. time between orders = 12.5 time between orders = 35 time between orders = 15.5 time between orders = 25

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock