Question: Part II: Practical case Consider a production line producing some commodity with a high failure rate ( maybe because of variance in materials, or difficulty

Part II: Practical case

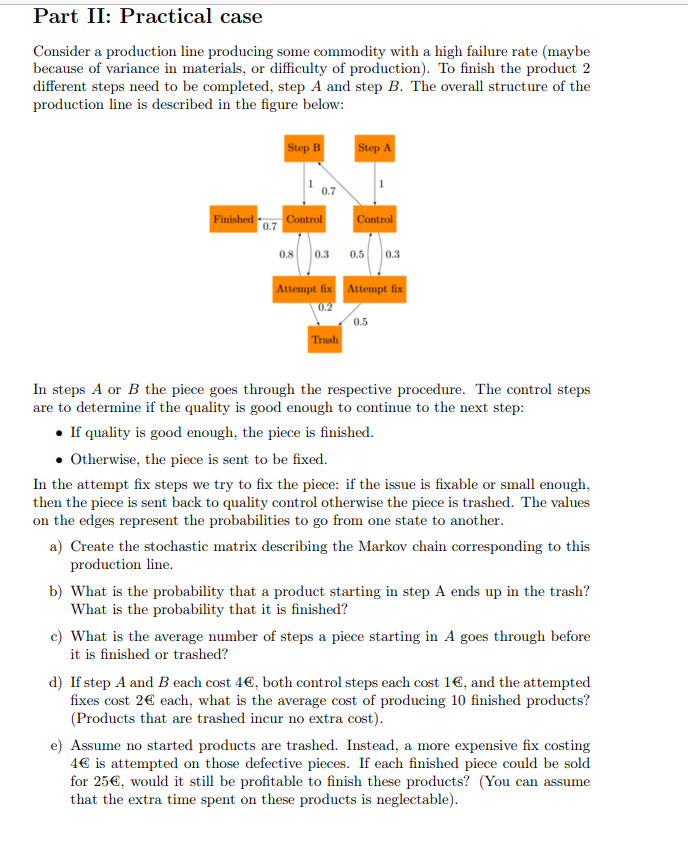

Consider a production line producing some commodity with a high failure rate maybe

because of variance in materials, or difficulty of production To finish the product

different steps need to be completed, step A and step The overall structure of the

production line is described in the figure below:

In steps or the piece goes through the respective procedure. The control steps

are to determine if the quality is good enough to continue to the next step:

If quality is good enough, the piece is finished.

Otherwise, the piece is sent to be fixed.

In the attempt fix steps we try to fix the piece: if the issue is fixable or small enough,

then the piece is sent back to quality control otherwise the piece is trashed. The values

on the edges represent the probabilities to go from one state to another.

To solve the following questions, use the method for reducible stochastic matrices!

b What is the probability that a product starting in step A ends up in the trash?

What is the probability that it is finished?

c What is the average number of steps a piece starting in A goes through before

it is finished or trashed?

d If step A and each cost both control steps each cost and the attempted

fixes cost each, what is the average cost of producing finished products?

Products that are trashed incur no extra cost

e Assume no started products are trashed. Instead, a more expensive fix costing

is attempted on those defective pieces. If each finished piece could be sold

for would it still be profitable to finish these products? You can assume

that the extra time spent on these products is neglectable

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock