Question: Part Lead time Order Quantity Expected Receipts 1 3 4 6 8 9 10 Period MPS Demand 2 15 On hand Inventory 40 5 20

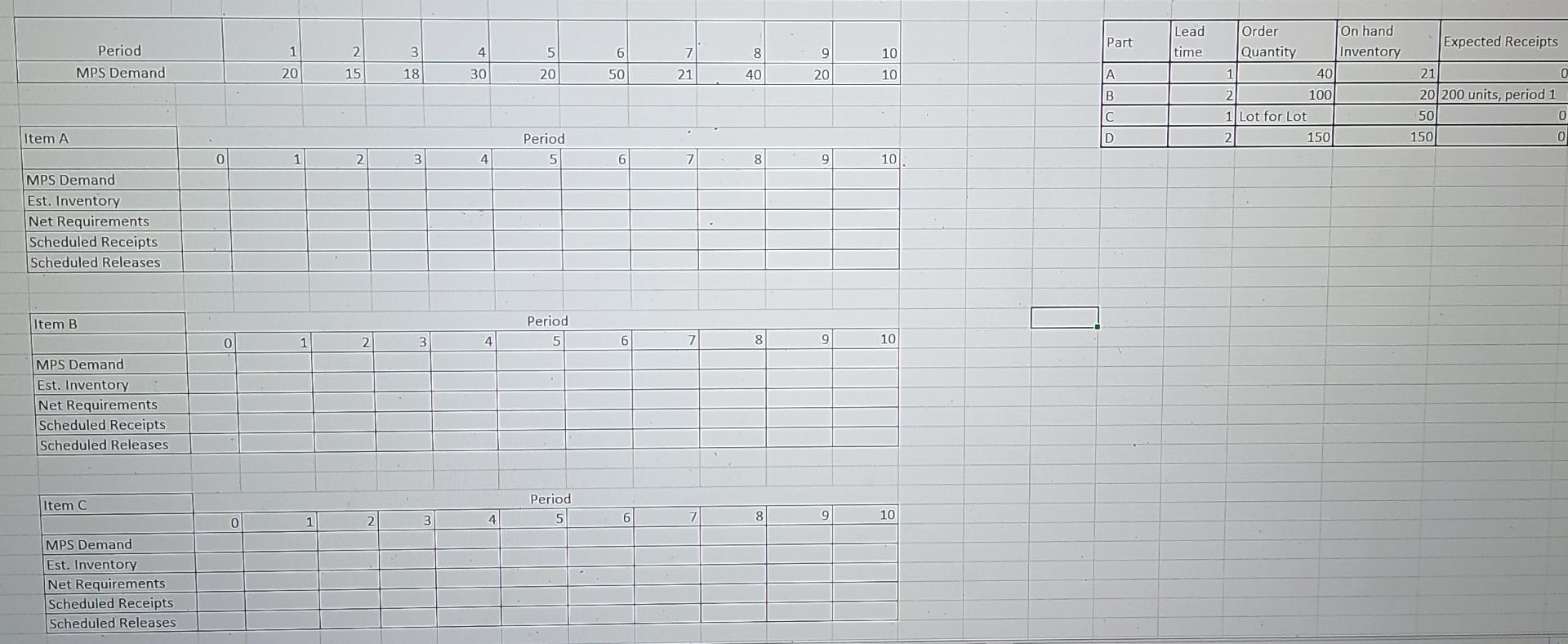

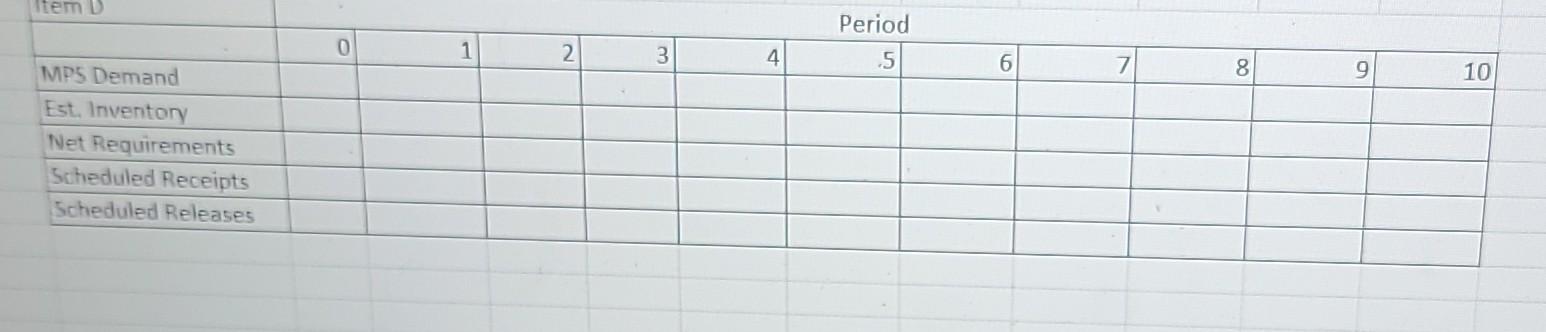

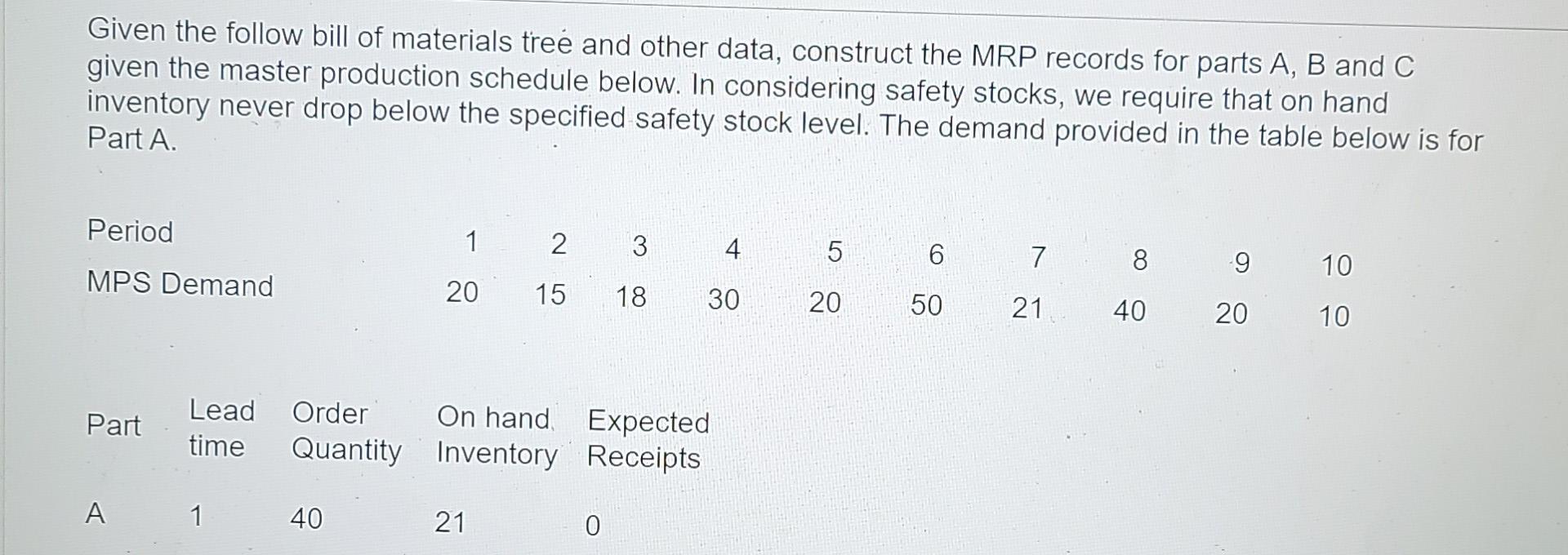

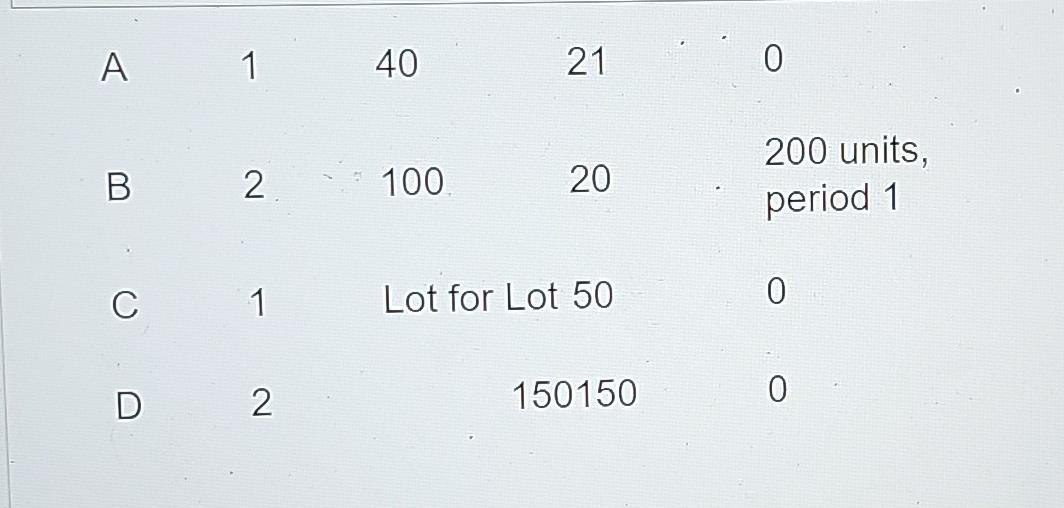

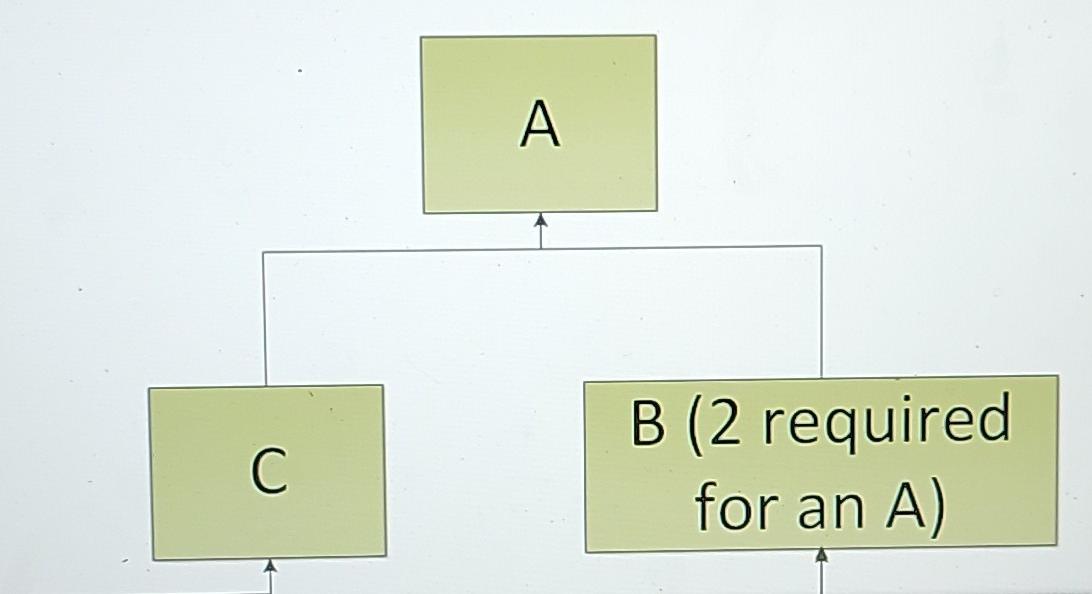

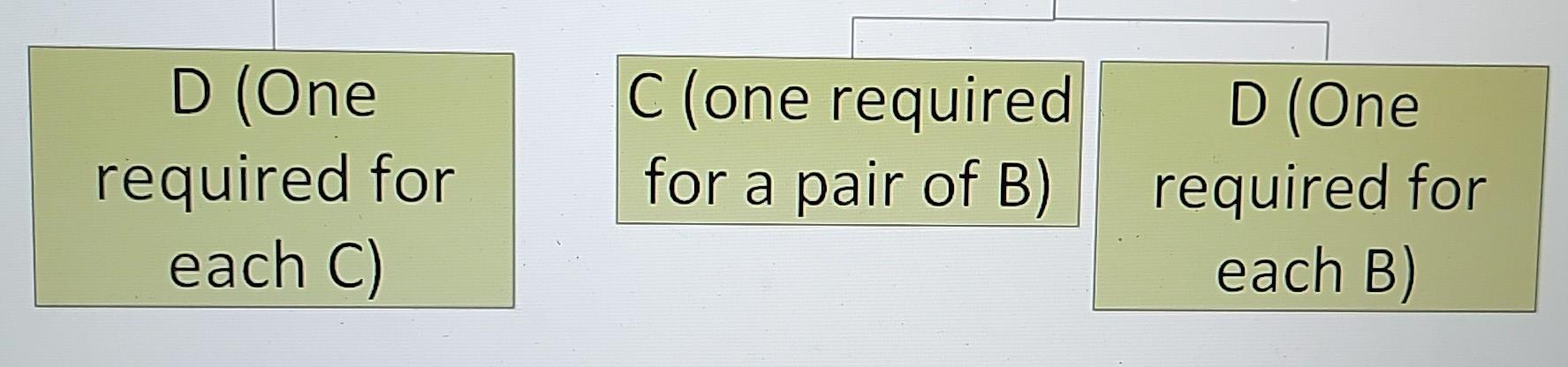

Part Lead time Order Quantity Expected Receipts 1 3 4 6 8 9 10 Period MPS Demand 2 15 On hand Inventory 40 5 20 20 18 00 30 50 21 40 20 10 A 21 B 2 100 1 Lot for Lot 150 20 200 units, period 1 50 0 150 0 Item A Period D 0 1 2 3 4 6 8 10 MPS Demand Est. Inventory Net Requirements Scheduled Receipts Scheduled Releases Item B Period 5 0 8 9 10 MPS Demand Est. Inventory Net Requirements Scheduled Receipts Scheduled Releases Item C Period 5 0 2 4 10 6 MPS Demand Est. Inventory Net Requirements Scheduled Receipts Scheduled Releases Item D Period 0 1 2 3 4 5 6 7 8 9 10 MPS Demand Est. Inventory Net Requirements Scheduled Receipts Scheduled Releases Given the follow bill of materials tree and other data, construct the MRP records for parts A, B and C given the master production schedule below. In considering safety stocks, we require that on hand inventory never drop below the specified safety stock level. The demand provided in the table below is for Part A. Period 1 2 3 4 5 6 7 8 9 10 MPS Demand 20 15 18 30 20 50 21 40 20 10 Part Lead time Order On hand Expected Quantity Inventory Receipts A 1 40 21 0 A 1 40 21 0 200 units, B 2 100 20 period 1 1 Lot for Lot 50 0 150150 0 D 2 A B (2 required for an A) D (One required for each C) C (one required for a pair of B) D (One required for each B)

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock