Question: perform a pareto analysis, draw a run chart, draw a fishbone , give three recommendations and discuss how TQM can help eco console to increase

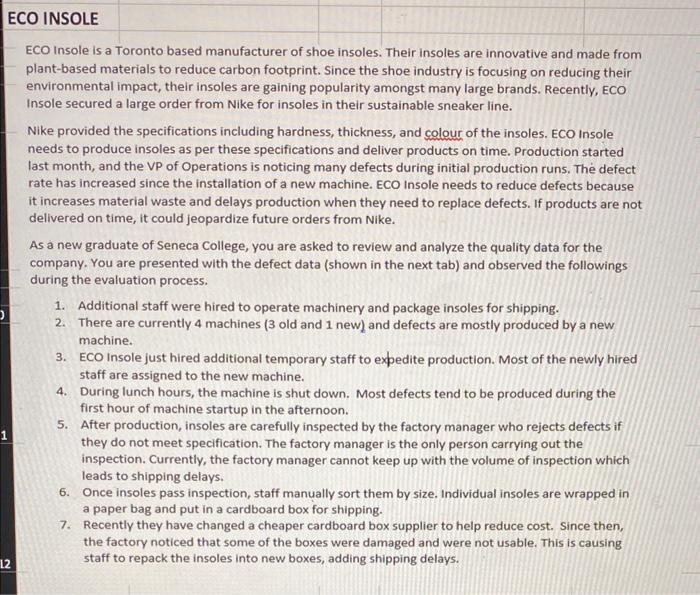

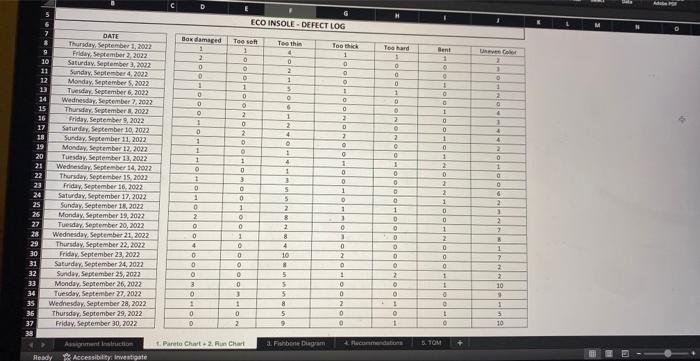

ECO Insole is a Toronto based manufacturer of shoe insoles. Their insoles are innovative and made from plant-based materials to reduce carbon footprint. Since the shoe industry is focusing on reducing their environmental impact, their insoles are gaining popularity amongst many large brands. Recently, ECO Insole secured a large order from Nike for insoles in their sustainable sneaker line. Nike provided the specifications including hardness, thickness, and colour of the insoles. ECO Insole needs to produce insoles as per these specifications and deliver products on time. Production started last month, and the VP of Operations is noticing many defects during initial production runs. The defect rate has increased since the installation of a new machine. ECO Insole needs to reduce defects because it increases material waste and delays production when they need to replace defects. If products are not delivered on time, it could jeopardize future orders from Nike. As a new graduate of Seneca College, you are asked to review and analyze the quality data for the company. You are presented with the defect data (shown in the next tab) and observed the followings during the evaluation process. 1. Additional staff were hired to operate machinery and package insoles for shipping. 2. There are currently 4 machines ( 3 old and 1 new) and defects are mostly produced by a new machine. 3. ECO Insole just hired additional temporary staff to expedite production. Most of the newly hired staff are assigned to the new machine. 4. During lunch hours, the machine is shut down. Most defects tend to be produced during the first hour of machine startup in the afternoon. 5. After production, insoles are carefully inspected by the factory manager who rejects defects if they do not meet specification. The factory manager is the only person carrying out the inspection. Currently, the factory manager cannot keep up with the volume of inspection which leads to shipping delays. 6. Once insoles pass inspection, staff manually sort them by size. Individual insoles are wrapped in a paper bag and put in a cardboard box for shipping. 7. Recently they have changed a cheaper cardboard box supplier to help reduce cost. Since then, the factory noticed that some of the boxes were damaged and were not usable. This is causing staff to repack the insoles into new boxes, adding shipping delays. Even though you do not have a technical background, you are asked to provide recommendations on how to reduce defects from an operational perspective. Assignment: (To be completed on the next tab "ECO Insole") 1. Perform a Pareto Analysis for the monthly Reject Log of the manufacturing process based on the total number of rejects from each category. Ensure you provide the Pareto Table and Chart. Include a text box with your observations on the Pareto Analysis ( 4 marks) 2. Draw a Run Chart (Line Chart) for the top 2 defects indicated on your Pareto Chart, using the monthly reject data. This chart should plot each day's rejects for the top 2 defects. Include a text box with your observations on the run chart. ( 4 marks) 3. Draw a Fish-Bone (Cause and Effect) diagram, which indicates some possible reasons for the defects listed in the case. Aim for at least 3-4 points on each line. (4 marks) 4. Include a text box and from the information you have discovered, give your top THREE recommendations to the VP of operations on how to reduce defects at ECO Insole. (one paragraph each, please number recommendations #1,2,3) ( 6 marks) 5. The VP of operations is thinking of incorporating the concept of Total Quality Management to their manufacturing process. Discuss how TQM can help ECO insole to increase the quality of their products. (Do not provide the concept of TQM. Discuss how TQM can be applied to ECO Insole) (6 marks) C D ECO INSOLE-DEFECT LOS EC

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts