Question: plase help eith these Question-1. Develop a bill of materials for your favorite meal. Identify the components that are purchased and the ones that are

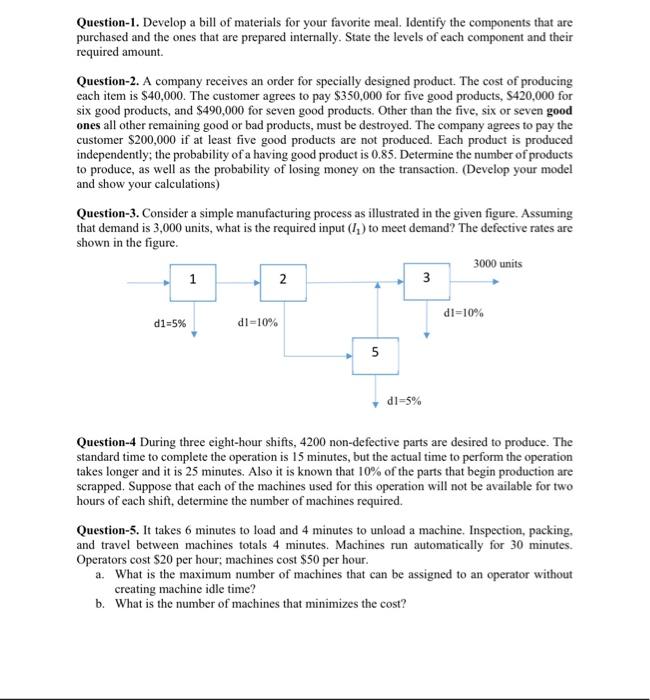

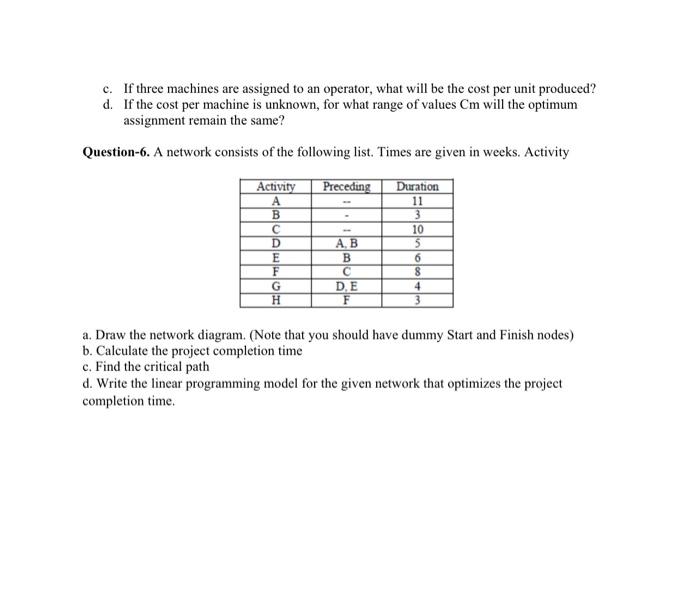

Question-1. Develop a bill of materials for your favorite meal. Identify the components that are purchased and the ones that are prepared internally. State the levels of each component and their required amount. Question-2. A company receives an order for specially designed product. The cost of producing each item is $40,000. The customer agrees to pay $350,000 for five good products, $420,000 for six good products, and $490,000 for seven good products. Other than the five, six or seven good ones all other remaining good or bad products, must be destroyed. The company agrees to pay the customer $200,000 if at least five good products are not produced. Each product is produced independently; the probability of a having good product is 0.85. Determine the number of products to produce, as well as the probability of losing money on the transaction. (Develop your model and show your calculations) Question-3. Consider a simple manufacturing process as illustrated in the given figure. Assuming that demand is 3,000 units, what is the required input (I1) to meet demand? The defective rates are shown in the figure. Question-4 During three eight-hour shifts, 4200 non-defective parts are desired to produce. The standard time to complete the operation is 15 minutes, but the actual time to perform the operation takes longer and it is 25 minutes. Also it is known that 10% of the parts that begin production are scrapped. Suppose that each of the machines used for this operation will not be available for two hours of each shift, determine the number of machines required. Question-5. It takes 6 minutes to load and 4 minutes to unload a machine. Inspection, packing, and travel between machines totals 4 minutes. Machines run automatically for 30 minutes. Operators cost $20 per hour; machines cost $50 per hour. a. What is the maximum number of machines that can be assigned to an operator without creating machine idle time? b. What is the number of machines that minimizes the cost? c. If three machines are assigned to an operator, what will be the cost per unit produced? d. If the cost per machine is unknown, for what range of values Cm will the optimum assignment remain the same? Question-6. A network consists of the following list. Times are given in weeks. Activity a. Draw the network diagram. (Note that you should have dummy Start and Finish nodes) b. Calculate the project completion time c. Find the critical path d. Write the linear programming model for the given network that optimizes the project completion time

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts