Question: please answer 1-4 completely. will upvote if complete Zhou Bicycle Company (ZBC), located in Seattle, is a whole- sale distributor of bicycles and bicycle parts.

please answer 1-4 completely. will upvote if complete

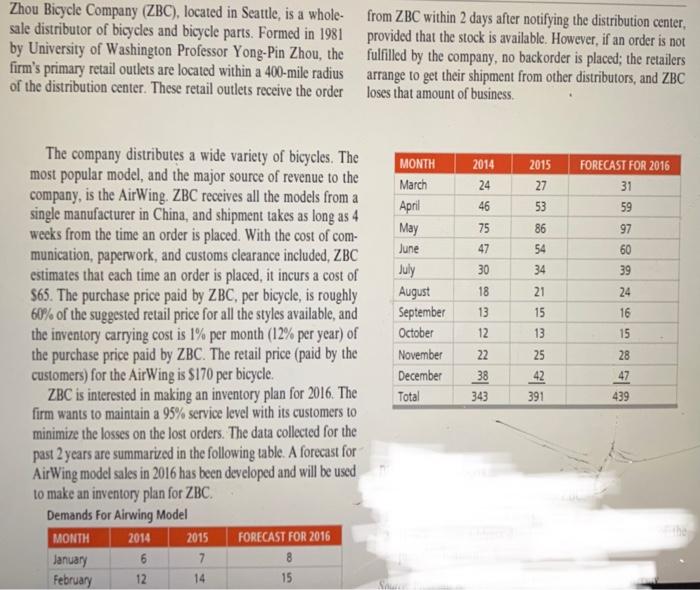

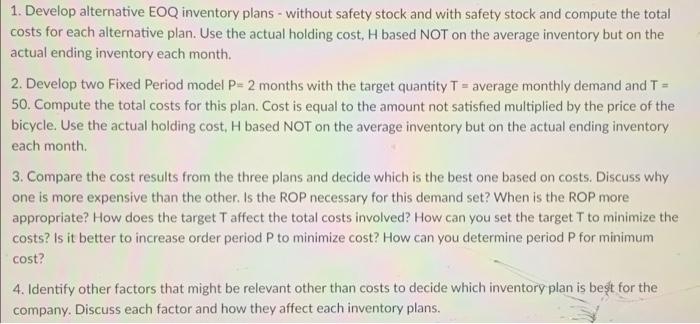

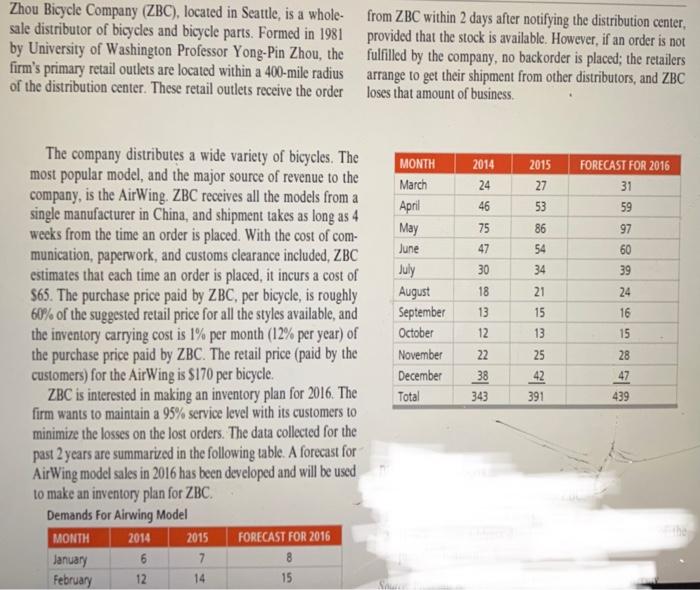

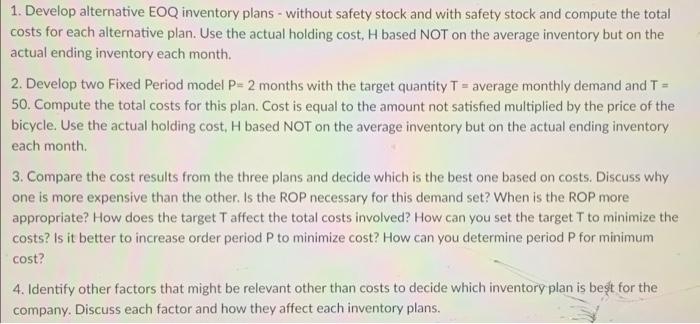

Zhou Bicycle Company (ZBC), located in Seattle, is a whole- sale distributor of bicycles and bicycle parts. Formed in 1981 by University of Washington Professor Yong-Pin Zhou, the firm's primary retail outlets are located within a 400-mile radius of the distribution center. These retail outlets receive the order The company distributes a wide variety of bicycles. The most popular model, and the major source of revenue to the company, is the AirWing. ZBC receives all the models from a single manufacturer in China, and shipment takes as long as 4 weeks from the time an order is placed. With the cost of com- munication, paperwork, and customs clearance included, ZBC estimates that each time an order is placed, it incurs a cost of $65. The purchase price paid by ZBC, per bicycle, is roughly 60% of the suggested retail price for all the styles available, and the inventory carrying cost is 1% per month ( 12% per year) of the purchase price paid by ZBC. The retail price (paid by the customers) for the AirWing is $170 per bicycle. ZBC is interested in making an inventory plan for 2016. The firm wants to maintain a 95% service level with its customers to minimize the losses on the lost orders. The data collected for the past 2 years are summarized in the following table. A forecast for AirWing model sales in 2016 has been developed and will be used to make an inventory plan for ZBC. Demands For Airwing Model MONTH 2014 6 12 January February 2015 7 14 FORECAST FOR 2016 8 15 from ZBC within 2 days after notifying the distribution center, provided that the stock is available. However, if an order is not fulfilled by the company, no backorder is placed; the retailers arrange to get their shipment from other distributors, and ZBC loses that amount of business. MONTH March 2014 24 April 46 May 75 June 47 July 30 18 August September October 13 12 November 22 December Total 38 343 Souter 2015 27 53 86 54 34 21 15 13 25 42 391 FORECAST FOR 2016 31 59 97 60 39 24 16 15 28 47 439 1. Develop alternative EOQ inventory plans - without safety stock and with safety stock and compute the total costs for each alternative plan. Use the actual holding cost, H based NOT on the average inventory but on the actual ending inventory each month. 2. Develop two Fixed Period model P= 2 months with the target quantity T = average monthly demand and T = 50. Compute the total costs for this plan. Cost is equal to the amount not satisfied multiplied by the price of the bicycle. Use the actual holding cost, H based NOT on the average inventory but on the actual ending inventory each month. 3. Compare the cost results from the three plans and decide which is the best one based on costs. Discuss why one is more expensive than the other. Is the ROP necessary for this demand set? When is the ROP more appropriate? How does the target T affect the total costs involved? How can you set the target T to minimize the costs? Is it better to increase order period P to minimize cost? How can you determine period P for minimum cost? 4. Identify other factors that might be relevant other than costs to decide which inventory plan is best for the company. Discuss each factor and how they affect each inventory plans

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock