Question: Please answer #8 in excel format with the formulas showing. Screenshots work perfectly! Subcontracting cost = $75 per unit 8. Refer to the data in

Please answer #8 in excel format with the formulas showing. Screenshots work perfectly!

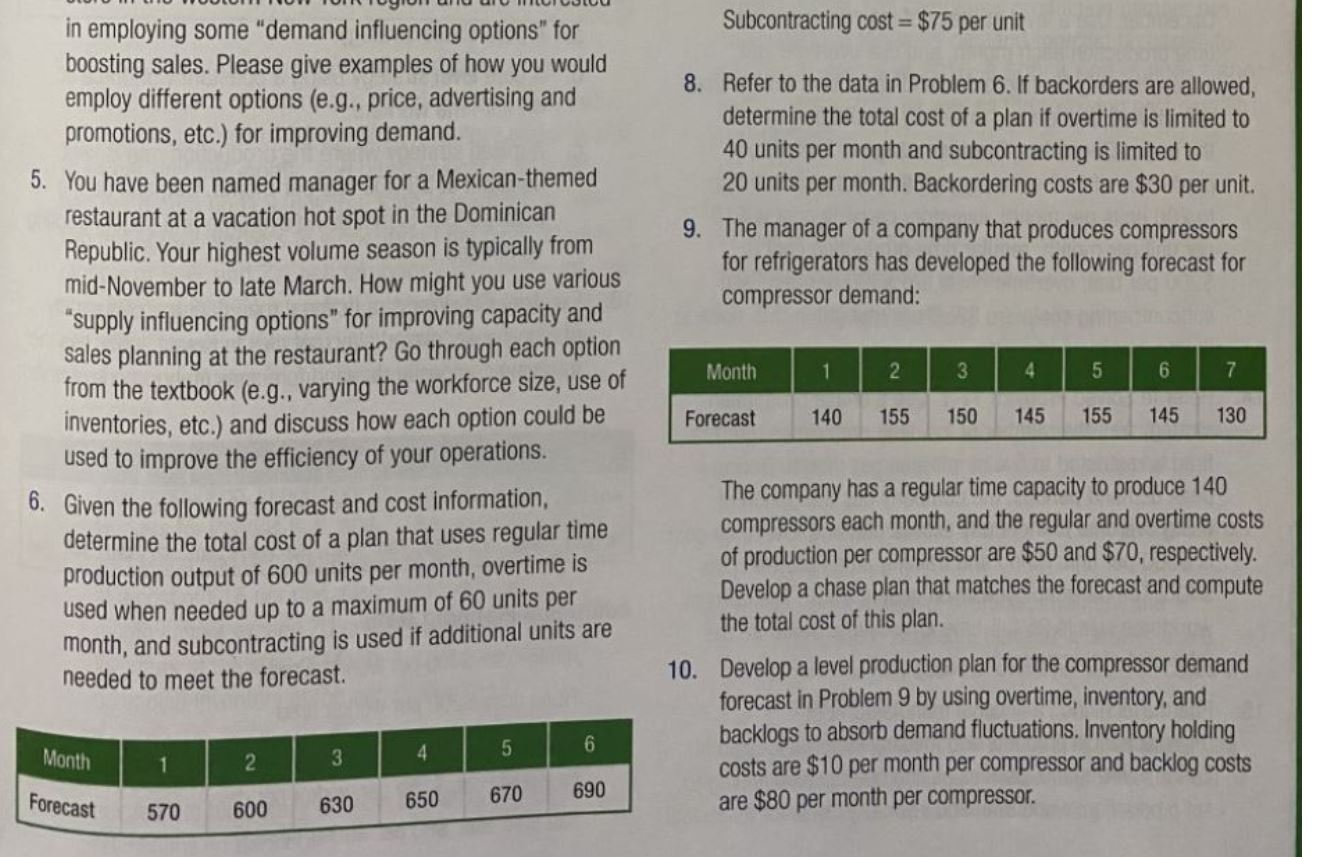

Subcontracting cost = $75 per unit 8. Refer to the data in Problem 6. If backorders are allowed, determine the total cost of a plan if overtime is limited to 40 units per month and subcontracting is limited to 20 units per month. Backordering costs are $30 per unit. 9. The manager of a company that produces compressors for refrigerators has developed the following forecast for compressor demand: in employing some "demand influencing options" for boosting sales. Please give examples of how you would employ different options (e.g., price, advertising and promotions, etc.) for improving demand. 5. You have been named manager for a Mexican-themed restaurant at a vacation hot spot in the Dominican Republic. Your highest volume season is typically from mid-November to late March. How might you use various "supply influencing options" for improving capacity and sales planning at the restaurant? Go through each option from the textbook (e.g., varying the workforce size, use of inventories, etc.) and discuss how each option could be used to improve the efficiency of your operations. 6. Given the following forecast and cost information, determine the total cost of a plan that uses regular time production output of 600 units per month, overtime is used when needed up to a maximum of 60 units per month, and subcontracting is used if additional units are needed to meet the forecast. Month 1 2 4 5 6 7 w Forecast 140 155 150 145 155 145 130 The company has a regular time capacity to produce 140 compressors each month, and the regular and overtime costs of production per compressor are $50 and $70, respectively. Develop a chase plan that matches the forecast and compute the total cost of this plan. 10. Develop a level production plan for the compressor demand forecast in Problem 9 by using overtime, inventory, and backlogs to absorb demand fluctuations. Inventory holding costs are $10 per month per compressor and backlog costs are $80 per month per compressor. 6 5 Month 4 2 3 Forecast 690 670 600 650 570 630Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock