Question: please answer all items thanks There are four steps in the manufacturing process of a stuffed toy: cutting, stuffing, sealing, and packaging. There are three

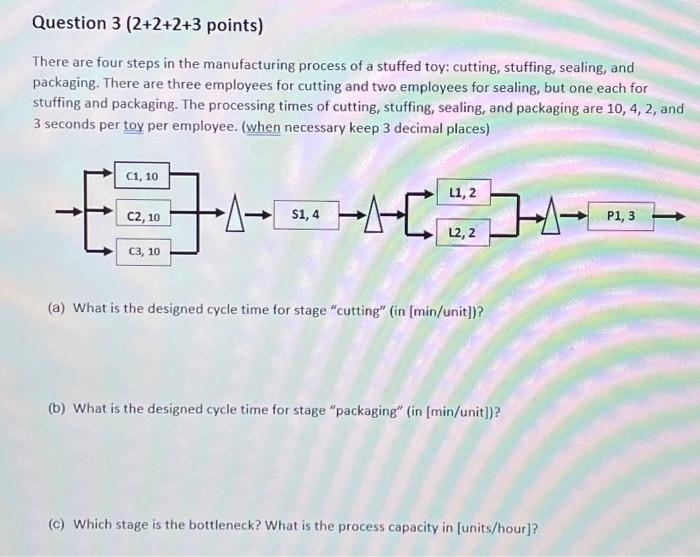

There are four steps in the manufacturing process of a stuffed toy: cutting, stuffing, sealing, and packaging. There are three employees for cutting and two employees for sealing, but one each for stuffing and packaging. The processing times of cutting, stuffing, sealing, and packaging are 10,4,2, and 3 seconds per toy per employee. (when necessary keep 3 decimal places) (a) What is the designed cycle time for stage "cutting" (in [min/unit])? (b) What is the designed cycle time for stage "packaging" (in [min/unit])? (c) Which stage is the bottleneck? What is the process capacity in [units/hour]? (a) What is the designed cycle time for stage "cutting" (in [ min/ unit])? (b) What is the designed cycle time for stage "packaging" (in [ min/ unit])? (c) Which stage is the bottleneck? What is the process capacity in [units/hour]? (d) If you can add one employee in parallel at the bottleneck stage, what should be the capacity of a new employee so that you increase the process capacity as much as possible (in [units/min])

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts