Question: please answer all parts in detail or do not answer at all. *This question is only available to reference the following questios, it is not

please answer all parts in detail or do not answer at all.

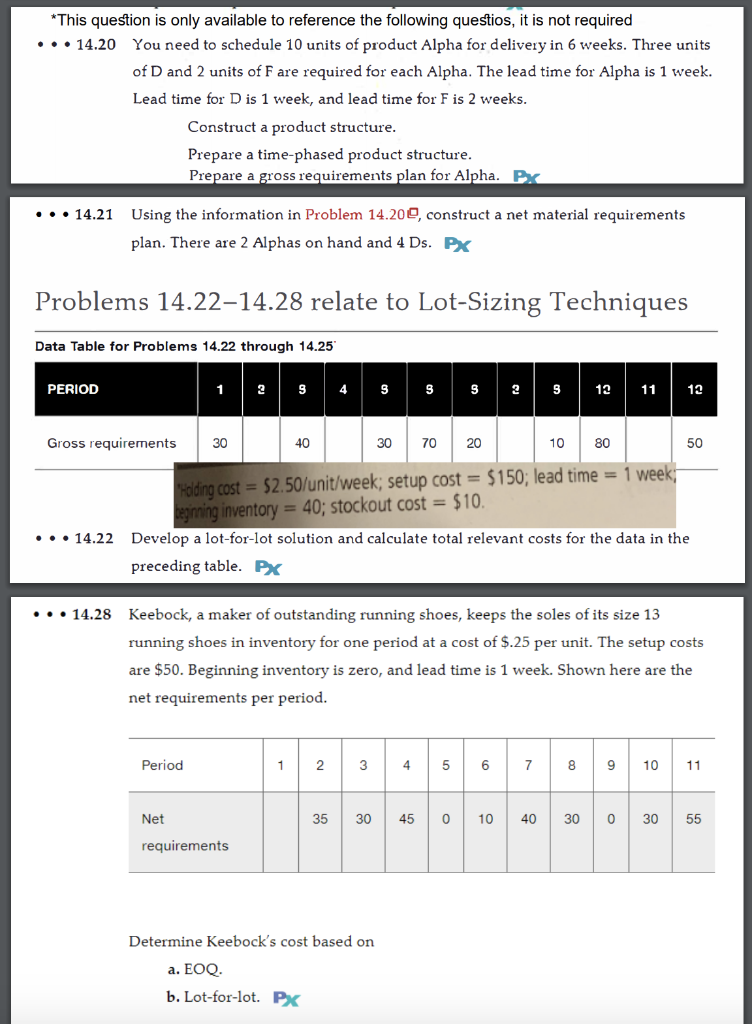

*This question is only available to reference the following questios, it is not required ... 14.20 You need to schedule 10 units of product Alpha for delivery in 6 weeks. Three units of D and 2 units of F are required for each Alpha. The lead time for Alpha is 1 week. Lead time for D is 1 week, and lead time for F is 2 weeks. Construct a product structure. Prepare a time-phased product structure. Prepare a gross requirements plan for Alpha. Px ...14.21 Using the information in Problem 14.200, construct a net material requirements plan. There are 2 Alphas on hand and 4 Ds. Px Problems 14.2214.28 relate to Lot-Sizing Techniques Data Table for Problems 14.22 through 14.25 PERIOD 1 9 4 3 3 2 3 12 11 12 Gross requirements 30 40 30 70 20 10 80 50 Holding cost = $2.50/unit/week; setup cost = $150; lead time = 1 week, eginning inventory = 40; stockout cost = $10. ... 14.22 Develop a lot-for-lot solution and calculate total relevant costs for the data in the preceding table. Px ... 14.28 Keebock, a maker of outstanding running shoes, keeps the soles of its size 13 running shoes in inventory for one period at a cost of $.25 per unit. The setup costs are $50. Beginning inventory is zero, and lead time is 1 week. Shown here are the net requirements per period. Period 1 2 5 11 Net 35 30 45 0 10 40 30 0 30 55 requirements Determine Keebock's cost based on a. EOQ. b. Lot-for-lot. PX *This question is only available to reference the following questios, it is not required ... 14.20 You need to schedule 10 units of product Alpha for delivery in 6 weeks. Three units of D and 2 units of F are required for each Alpha. The lead time for Alpha is 1 week. Lead time for D is 1 week, and lead time for F is 2 weeks. Construct a product structure. Prepare a time-phased product structure. Prepare a gross requirements plan for Alpha. Px ...14.21 Using the information in Problem 14.200, construct a net material requirements plan. There are 2 Alphas on hand and 4 Ds. Px Problems 14.2214.28 relate to Lot-Sizing Techniques Data Table for Problems 14.22 through 14.25 PERIOD 1 9 4 3 3 2 3 12 11 12 Gross requirements 30 40 30 70 20 10 80 50 Holding cost = $2.50/unit/week; setup cost = $150; lead time = 1 week, eginning inventory = 40; stockout cost = $10. ... 14.22 Develop a lot-for-lot solution and calculate total relevant costs for the data in the preceding table. Px ... 14.28 Keebock, a maker of outstanding running shoes, keeps the soles of its size 13 running shoes in inventory for one period at a cost of $.25 per unit. The setup costs are $50. Beginning inventory is zero, and lead time is 1 week. Shown here are the net requirements per period. Period 1 2 5 11 Net 35 30 45 0 10 40 30 0 30 55 requirements Determine Keebock's cost based on a. EOQ. b. Lot-for-lot. PX

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts