Question: please answer completely and thoroughly Under what conditions might a lead firm choose to develop a supplier rather than replace them? Supplier Development and Capability

please answer completely and thoroughly

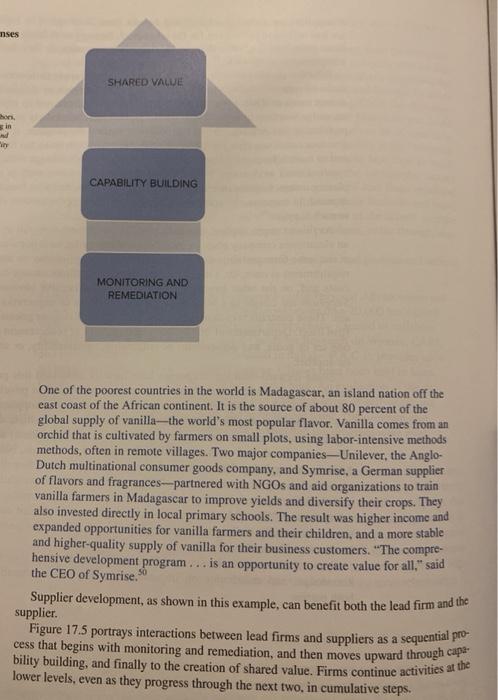

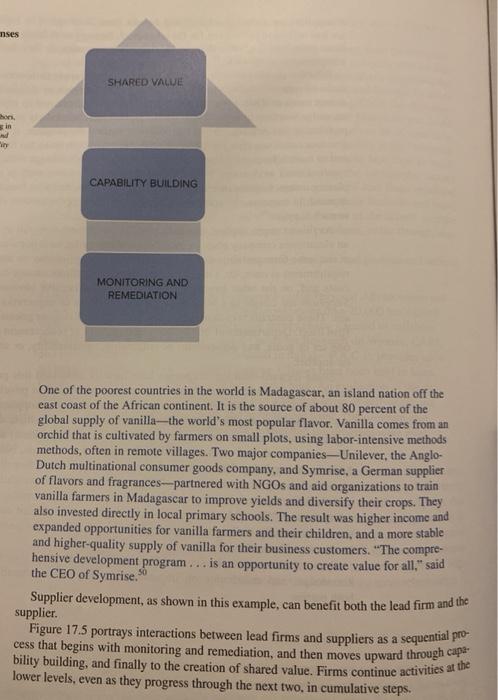

Supplier Development and Capability Building A growing trend is for lead firms to work collaboratively with their suppliers to help them improve their social, ethical, and environmental performance. The term supplier develop- ment refers to activities undertaken by companies to improve the performance of firms in their supply chains. Rather than terminate or punish a supplier, a lead firm may choose instead to invest time and resources to build the supplier's capabilities. Such an approach starts from the premise that many suppliers wish to comply, but simply lack the managerial skill, technical knowledge, or resources to do so. Why would lead firms decide to engage in capability building, rather than simply give their contracts to someone else- or even do the work themselves? One reason is that the cost of switching suppliers may be too high. A supplier may have critical capabilities, such as technical expertise in making a specific product, or other attributes that the lead firm values, such as relationships with other firms farther upstream in the supply chain. The lead firm may feel a moral obligation to the workers and local community not to cause job loss. Or, other suppliers may not be readily available to take over the contract. 43 For many reasons, then, a lead firm may find it preferable to work with a supplier to improve its performance. Supplier development may take several forms, including training, joint problem solv. ing, and investing in equipment or infrastructure. An example of a company with a robust training program is Cisco Systems, which designs and markets networking equipment that is manufactured by more than 600 suppliers in Asia, the Americas, and Europe. To assure that these partners comply fully with its supplier code of conduct, Cisco has developed an online training library, run a series of webinars in English and Mandarin, and paired suppliers to share best practices. Sometimes, technical assistance can be of great help. For example, a global apparel firm trained managers at a supplier factory in the Dominican Republic, where workers had complained repeatedly about excessive heat, how to install a new ventilation system, fans, and water coolers. Following the catastrophic factory collapse in Bangladesh, mentioned earlier in this chapter, dozens of lead firms organized as the Accord on Fire and Building Safety inspected 1.100 supplier factories and found structural deficiencies in more than 100 of them. Under the terms of the accord, member brands committed to providing funds to correct these safety problems, either through loans or favorable contract terms. Some companies have invested directly in improving the lives and professional skills of their suppliers' workers. Gap Inc., the apparel retailer, supports a program called Personal Advancement and Career Enhancement, or P.A.C.E., which has served more than 20,000 low-skilled women garment workers throughout its global supply chain. Created in collabora- tion with several NGOs--the International Center for Research on Women, CARE, and the Swasti Health Resource Centre (located in India)-P.A.C.E. provides up to 80 hours of free life skills and technical training. Classes have been held in India, Cambodia, Vietnam, Bangladesh, Sri Lanka, and China. An evaluation of the pro- gram showed that women who participated had a greater sense of self-worth and were better able to manage their work and professional lives. The program also decreased worker turnover, and women who completed the program were more likely to be promoted at work." This initiative went beyond the factory walls to empower women and build communities. Lead firms can provide a variety of rewards or incentives to suppliers that collaborate to build capabilities. Cisco, for example, gives preference to otherwise qualified suppliers that meet certain sustainability standards. Starbucks offers farmers that achieve high marks in its CAF (Coffee and Farmer Equity) program-which scores coffee producers on social and environmental criteriaa premium price for their coffee beans. Research has shown that capability building initiatives work best where interactions between buyer and sup plier are frequent and ongoing, and where the two parties have a long-term relationship." If suppliers are unconvinced they will benefit from more orders or higher margins, they are less willing to participate. On the other hand, they are more likely to engage when lead firms are prepared to offer them stable, long-term contracts, so they feel that investing in compliance is worthwhile." Effective supplier development often involves careful study to determine the underlying as root cause analysis. For example, Nike's supplier audits turned up repeated instances of excessive overtime in apparel manufacturing factories, particularly in China, despite rules prohibiting this practice. When the company studied the problem, it found that the big- gest root cause was style proliferation-asking factories to make too many different styles and to switch frequently from one style to another. Each change reduced efficiency and required extra work hours. Nike also found other root causes, such as miscalculations in placing orders, last-minute changes in colors and fabrics, and poor forecasting of customer demand. In response, the company committed to reducing the number of styles contracted to each supplier. As this example implies, demands placed on suppliers may run at cross-purposes. If an electronics company places a rush, high-volume order for a popular new product, and at the same time prohibits excessive overtime, the supplier may be unable to fulfill both requirements at once. Or, a lead firm may pressure suppliers, on one hand, for ever-lower costs and, on the other hand, for compliance with expensive environmental standards. Suppliers are caught in a bind, not knowing which set of expectations is more import- ant. These contradictory demands sometimes reflect divergent priorities within the lead firm itself. Departments of supply chain management or procurement may be focused on one set of goals, and departments of citizenship, sustainability, or social responsibility on another. Some forward-thinking companies have directly addressed this problem. They have developed organizational mechanisms to resolve differences in priorities internally, and they have tried to communicate expectations more clearly to suppliers. One trend is the use of integrated supplier scorecards that rate suppliers on multiple dimensions, includ- ing both traditional measures (such as cost. quality, and timeliness) and newer measures of social, ethical, and environmental performance. For example, Nike has introduced a Manufacturing Index that measures and rewards suppliers on four dimensions--quality, on-time delivery, cost, and sustainability--each of which is weighted 25 percent. (The sustainability factor is broadly defined to include social, environmental, and health and safety issues.) The [Manufacturing) Index enables us to reward contract factories that score consistently well across all categories," said Nike's vice president of sustainable business and innovation." Research shows that when companies invest in suppliers and their employees, exchange knowledge, and collaborate on improvements, they create shared value that benefits 49 both parties. nses SHARED VALUE in in CAPABILITY BUILDING MONITORING AND REMEDIATION One of the poorest countries in the world is Madagascar, an island nation off the east coast of the African continent. It is the source of about 80 percent of the global supply of vanilla--the world's most popular flavor. Vanilla comes from an orchid that is cultivated by farmers on small plots, using labor-intensive methods methods, often in remote villages. Two major companies-Unilever, the Anglo- Dutch multinational consumer goods company, and Symrise, a German supplier of flavors and fragrances--partnered with NGOs and aid organizations to train vanilla farmers in Madagascar to improve yields and diversify their crops. They also invested directly in local primary schools. The result was higher income and expanded opportunities for vanilla farmers and their children, and a more stable and higher-quality supply of vanilla for their business customers. "The compre- hensive development program is an opportunity to create value for all," said the CEO of Symrise. Supplier development, as shown in this example, can benefit both the lead firm and the supplier Figure 17.5 portrays interactions between lead firms and suppliers as a sequential pro cess that begins with monitoring and remediation, and then moves upward through cups bility building, and finally to the creation of shared value. Firms continue activities at the lower levels, even as they progress through the next two, in cumulative steps

Under what conditions might a lead firm choose to develop a supplier rather than replace them?

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock