Question: Please answer question 2 in excel 1. The Grebski Auto Repair Shop uses a shop floor control system based on forward scheduling to determine auto

Please answer question 2 in excel

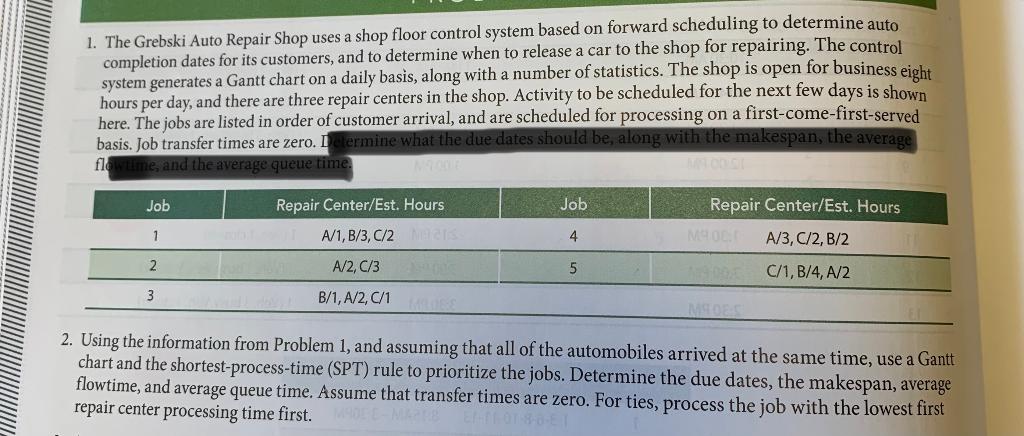

1. The Grebski Auto Repair Shop uses a shop floor control system based on forward scheduling to determine auto completion dates for its customers, and to determine when to release a car to the shop for repairing. The control system generates a Gantt chart on a daily basis , along with a number of statistics. The shop is open for business eight hours per day, and there are three repair centers in the shop. Activity to be scheduled for the next few days is shown here. The jobs are listed in order of customer arrival, and are scheduled for processing on a first-come-first-served basis. Job transfer times are zero. Determine what the due dates should be, along with the makespan, the average flatime, and the average queue time. Job Repair Center/Est. Hours Job 1 A/1,B/3,C/2 4 Repair Center/Est. Hours NEO A/3, C/2, B/2 C/1,B/4, A/2 A/2, C/3 5 3 B/1, A/2,C/1 2. Using the information from Problem 1, and assuming that all of the automobiles arrived at the same time, use a Gantt chart and the shortest-process-time (SPT) rule to prioritize the jobs. Determine the due dates, the makespan, average flowtime, and average queue time. Assume that transfer times are zero. For ties, process the job with the lowest first repair center processing time first. 1. The Grebski Auto Repair Shop uses a shop floor control system based on forward scheduling to determine auto completion dates for its customers, and to determine when to release a car to the shop for repairing. The control system generates a Gantt chart on a daily basis , along with a number of statistics. The shop is open for business eight hours per day, and there are three repair centers in the shop. Activity to be scheduled for the next few days is shown here. The jobs are listed in order of customer arrival, and are scheduled for processing on a first-come-first-served basis. Job transfer times are zero. Determine what the due dates should be, along with the makespan, the average flatime, and the average queue time. Job Repair Center/Est. Hours Job 1 A/1,B/3,C/2 4 Repair Center/Est. Hours NEO A/3, C/2, B/2 C/1,B/4, A/2 A/2, C/3 5 3 B/1, A/2,C/1 2. Using the information from Problem 1, and assuming that all of the automobiles arrived at the same time, use a Gantt chart and the shortest-process-time (SPT) rule to prioritize the jobs. Determine the due dates, the makespan, average flowtime, and average queue time. Assume that transfer times are zero. For ties, process the job with the lowest first repair center processing time firstStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock