Question: please answer question (b) only using excel. thank you WonderWorld is a company that produces household furniture. The company wishes to implement an MRP system

please answer question (b) only using excel. thank you

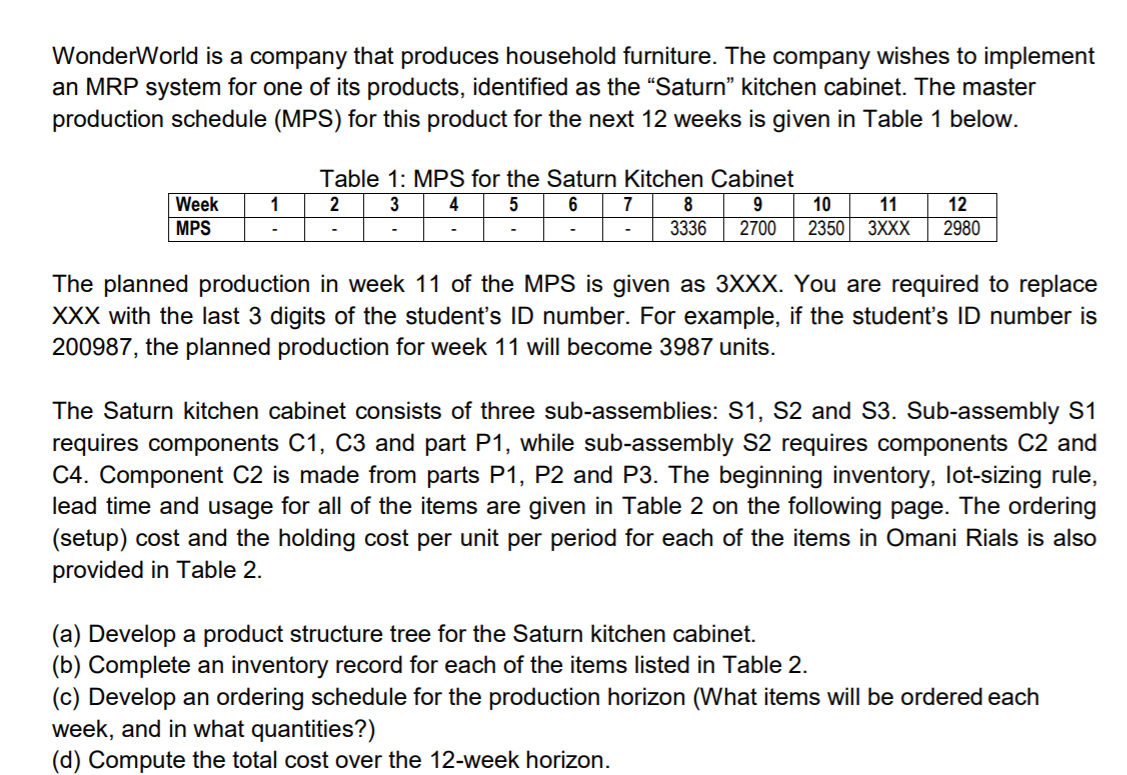

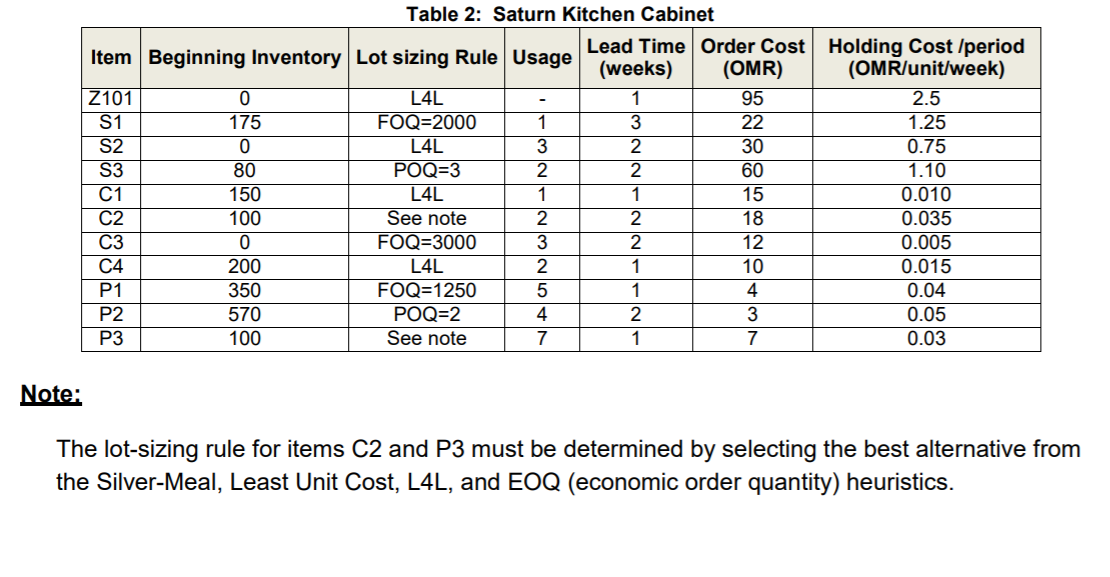

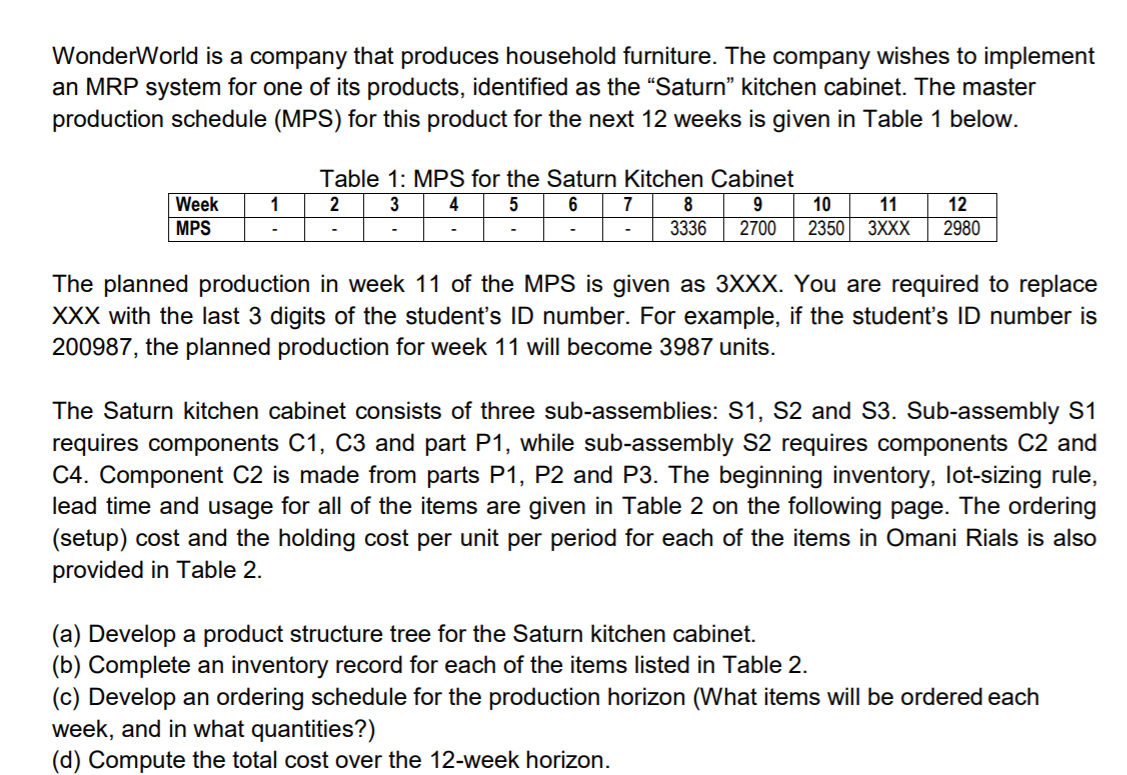

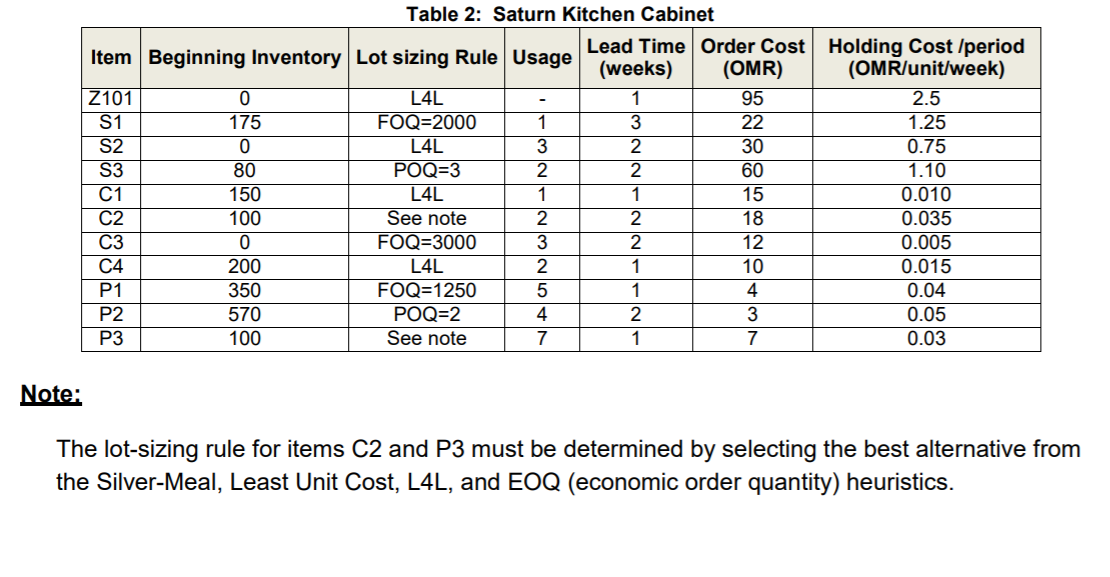

WonderWorld is a company that produces household furniture. The company wishes to implement an MRP system for one of its products, identified as the "Saturn kitchen cabinet. The master production schedule (MPS) for this product for the next 12 weeks is given in Table 1 below. 1 Week MPS Table 1: MPS for the Saturn Kitchen Cabinet 2 3 4 5 6 7 8 9 3336 2700 10 11 2350 3XXX 12 2980 The planned production in week 11 of the MPS is given as 3XXX. You are required to replace XXX with the last 3 digits of the student's ID number. For example, if the student's ID number is 200987, the planned production for week 11 will become 3987 units. The Saturn kitchen cabinet consists of three sub-assemblies: S1, S2 and 53. Sub-assembly S1 requires components C1, C3 and part P1, while sub-assembly S2 requires components C2 and C4. Component C2 is made from parts P1, P2 and P3. The beginning inventory, Iot-sizing rule, lead time and usage for all of the items are given in Table 2 on the following page. The ordering (setup) cost and the holding cost per unit per period for each of the items in Omani Rials is also provided in Table 2. (a) Develop a product structure tree for the Saturn kitchen cabinet. (b) Complete an inventory record for each of the items listed in Table 2. (C) Develop an ordering schedule for the production horizon (What items will be ordered each week, and in what quantities?) (d) Compute the total cost over the 12-week horizon. Table 2: Saturn Kitchen Cabinet Lead Time Order Cost Holding Cost /period Item Beginning Inventory Lot sizing Rule Usage (weeks) (OMR) (OMR/unit/week) Z101 0 L4L 1 95 2.5 S1 175 FOQ=2000 1 3 22 1.25 S2 0 L4L 3 2 30 0.75 S3 80 POQ=3 2 2 60 1.10 C1 150 L4L 1 1 15 0.010 C2 100 See note 2 2 18 0.035 C3 0 FOQ=3000 3 2 12 0.005 C4 200 L4L 2 1 10 0.015 P1 350 FOQ=1250 5 1 4 0.04 P2 570 POQ=2 4 2 3 0.05 P3 100 See note 7 1 7 0.03 Note: The lot-sizing rule for items C2 and P3 must be determined by selecting the best alternative from the Silver-Meal, Least Unit Cost, L4L, and EOQ (economic order quantity) heuristics. WonderWorld is a company that produces household furniture. The company wishes to implement an MRP system for one of its products, identified as the "Saturn kitchen cabinet. The master production schedule (MPS) for this product for the next 12 weeks is given in Table 1 below. 1 Week MPS Table 1: MPS for the Saturn Kitchen Cabinet 2 3 4 5 6 7 8 9 3336 2700 10 11 2350 3XXX 12 2980 The planned production in week 11 of the MPS is given as 3XXX. You are required to replace XXX with the last 3 digits of the student's ID number. For example, if the student's ID number is 200987, the planned production for week 11 will become 3987 units. The Saturn kitchen cabinet consists of three sub-assemblies: S1, S2 and 53. Sub-assembly S1 requires components C1, C3 and part P1, while sub-assembly S2 requires components C2 and C4. Component C2 is made from parts P1, P2 and P3. The beginning inventory, Iot-sizing rule, lead time and usage for all of the items are given in Table 2 on the following page. The ordering (setup) cost and the holding cost per unit per period for each of the items in Omani Rials is also provided in Table 2. (a) Develop a product structure tree for the Saturn kitchen cabinet. (b) Complete an inventory record for each of the items listed in Table 2. (C) Develop an ordering schedule for the production horizon (What items will be ordered each week, and in what quantities?) (d) Compute the total cost over the 12-week horizon. Table 2: Saturn Kitchen Cabinet Lead Time Order Cost Holding Cost /period Item Beginning Inventory Lot sizing Rule Usage (weeks) (OMR) (OMR/unit/week) Z101 0 L4L 1 95 2.5 S1 175 FOQ=2000 1 3 22 1.25 S2 0 L4L 3 2 30 0.75 S3 80 POQ=3 2 2 60 1.10 C1 150 L4L 1 1 15 0.010 C2 100 See note 2 2 18 0.035 C3 0 FOQ=3000 3 2 12 0.005 C4 200 L4L 2 1 10 0.015 P1 350 FOQ=1250 5 1 4 0.04 P2 570 POQ=2 4 2 3 0.05 P3 100 See note 7 1 7 0.03 Note: The lot-sizing rule for items C2 and P3 must be determined by selecting the best alternative from the Silver-Meal, Least Unit Cost, L4L, and EOQ (economic order quantity) heuristics