Question: please answer questions 1 and 2 for case study FORECASTING CHAPTER 8 355 concern about having enough rakes on hand to make timely shipments. Both

please answer questions 1 and 2 for case study

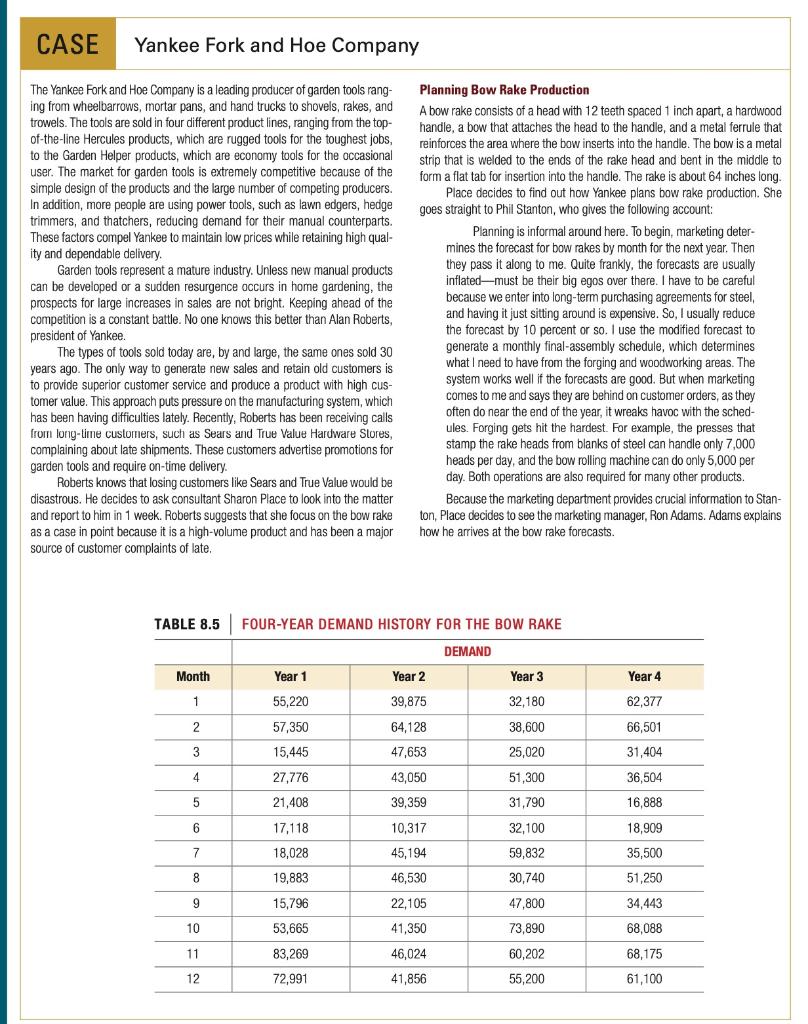

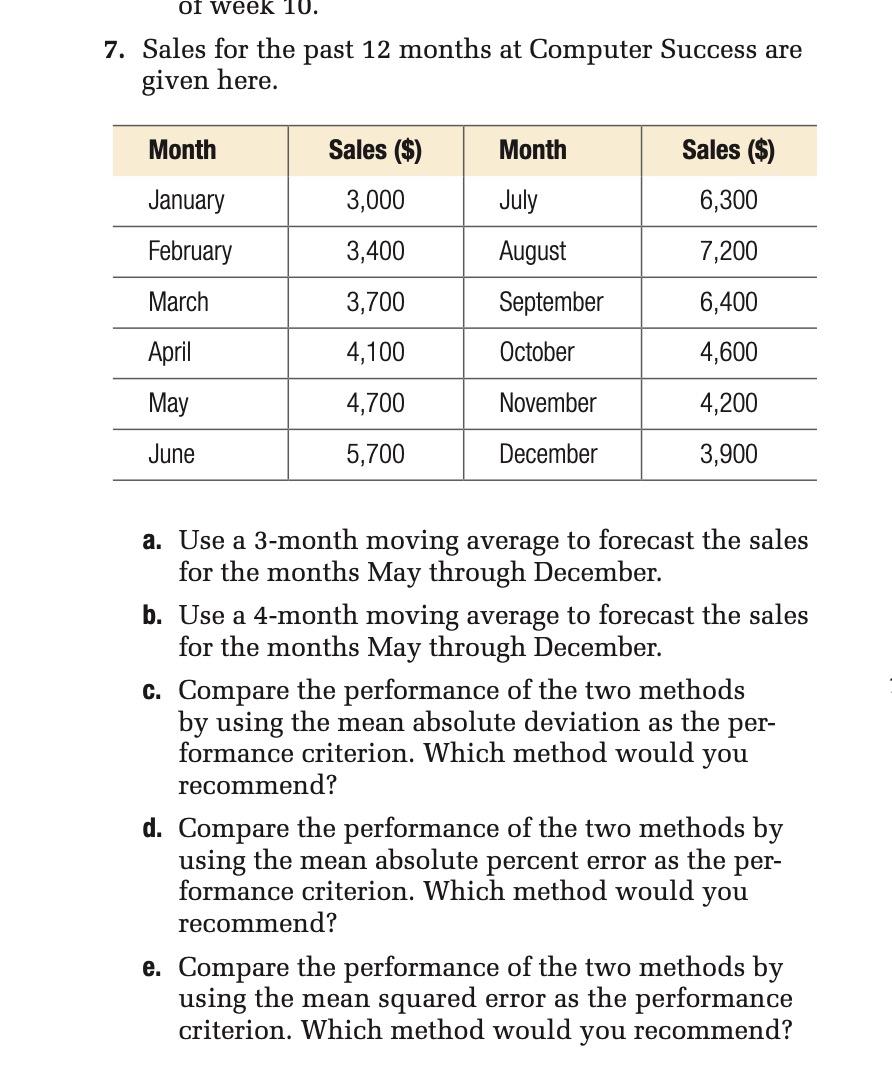

FORECASTING CHAPTER 8 355 concern about having enough rakes on hand to make timely shipments. Both are also somewhat concerned about capacity. Yet she decides to check actual customer demand for the bow rake over the past 4 years in Table 8.5) before making her final report to Roberts. Things do not change much from year to year. Sure, some- times we put on a sales promotion of some kind, but we try to give Phil enough warning before the demand kicks inusually a month or so. I meet with several managers from the various sales regions to go over shipping data from last year and discuss anticipated promotions, changes in the economy, and shortages we experi- enced last year. Based on these meetings, I generate a monthly forecast for the next year. Even though we take a lot of time getting the forecast, it never seems to help us avoid customer problems. QUESTIONS 1. Comment on the forecasting system being used by Yankee. Suggest changes or improvements that you believe are justified. 2. Develop your own forecast for bow rakes for each month of the next year (year 5). Justify your forecast and the method you used. The Problem Place ponders the comments from Stanton and Adams. She understands Stanton's concerns about costs and keeping inventory low and Adams' CASE Yankee Fork and Hoe Company The Yankee Fork and Hoe Company is a leading producer of garden tools rang- ing from wheelbarrows, mortar pans, and hand trucks to shovels, rakes, and trowels. The tools are sold in four different product lines, ranging from the top- of-the-line Hercules products, which are rugged tools for the toughest jobs, to the Garden Helper products, which are economy tools for the occasional user. The market for garden tools is extremely competitive because of the simple design of the products and the large number of competing producers. In addition, more people are using power tools, such as lawn edgers, hedge trimmers, and thatchers, reducing demand for their manual counterparts. These factors compel Yankee to maintain low prices while retaining high qual- ity and dependable delivery. Garden tools tools represent a mature industry. Unless new manual products can be developed or a or a sudden resurgence occurs in home gardening, the prospects for large increases in sales are not bright. Keeping ahead the competition is a constant battle. No one knows this better than Alan Roberts, president of Yankee The types of tools sold today are, by and large, the same ones sold 30 years ago. The only way to generate new sales and retain old customers is to provide superior customer service and produce a product with high cus- tomer value. This approach puts pressure on the manufacturing system, which has been having difficulties lately. Recently, Roberts has been receiving calls from long-time customers, such as Sears and True Value Hardware Stores, complaining about late shipments. These customers advertise promotions for garden tools and require on-time delivery. Roberts knows that losing customers like Sears and True Value would be disastrous. He decides to ask consultant Sharon Place to look into the matter and report to him in 1 week. Roberts suggests that she focus on the bow rake as a case in point because it is a high-volume product and has been a major source of customer complaints of late, Planning Bow Rake Production A bow rake consists of a head with 12 teeth spaced 1 inch apart, a hardwood handle, a bow that attaches the head to the handle, and a metal ferrule that reinforces the area where the bow inserts into the handle. The bow is a metal strip that is welded to the ends of the rake head and bent in the middle to form a flat tab for insertion into the handle. The rake is about 64 inches long. Place decides to find out how Yankee plans bow rake production. She goes straight to Phil Stanton, who gives the following account: Planning is informal around here. To begin, marketing deter- mines the forecast for bow rakes by month for the next year. Then they pass it along to me. Quite frankly, the forecasts are usually inflated-must be their big egos over there. I have to be careful because we enter into long-term purchasing agreements for steel, and having it just sitting around is expensive. So, I usually reduce the forecast by 10 percent or so. I use the modified forecast to generate a monthly final-assembly sche what I need to have from the ssembly schedule, which determines de e farging and woodworking areas. The system works well if the forecasts are good. But when marketing comes to me and says they are behind on customer orders, as they often do near the end of the year, it wreaks havoc with the sched- otton door the che ules. Forging gets hit the hardest. For example, the presses that stamp the rake heads from blanks of steel can handle only 7,000 heads per day, and the bow rolling machine can do only 5,000 per day. Both operations are also required for many other products. Because the marketing department provides crucial information to Stan- ton, Place decides to see the marketing manager, Ron Adams. Adams explains how he arrives at the bow rake forecasts. TABLE 8.5 FOUR-YEAR DEMAND HISTORY FOR THE BOW RAKE DEMAND Month Year 1 Year 2 Year 3 1 55,220 39,875 32,180 Year 4 62,377 66,501 2 57,350 64,128 38,600 3 15,445 47,653 25,020 31,404 4 27,776 43,050 51,300 36,504 5 21,408 39,359 31,790 16,888 6 17,118 32,100 59,832 10,317 45,194 46,530 18,909 35,500 7 18,028 8 19,883 30,740 51,250 9 15,796 22,105 47,800 34,443 10 53,665 41,350 73,890 68,088 11 83,269 46,024 60,202 68,175 12 72,991 41,856 55,200 61,100 of week 10. 7. Sales for the past 12 months at Computer Success are given here. Month Sales ($) Month Sales ($) January 3,000 July 6,300 February 3,400 August 7,200 March 3,700 September 6,400 April 4,100 October 4,600 May 4,700 November 4,200 June 5,700 December 3,900 a. Use a 3-month moving average to forecast the sales for the months May through December. b. Use a 4-month moving average to forecast the sales for the months May through December. C. Compare the performance of the two methods by using the mean absolute deviation as the per- formance criterion. Which method would you recommend? d. Compare the performance of the two methods by using the mean absolute percent error as the per- formance criterion. Which method would you recommend? e. Compare the performance of the two methods by using the mean squared error as the performance criterion. Which method would you recommend

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock