Question: Please Answer the following question with details Question 2: (10 points) A chocolate manufacturer wants to add a new production line that consists of 5

Please Answer the following question with details

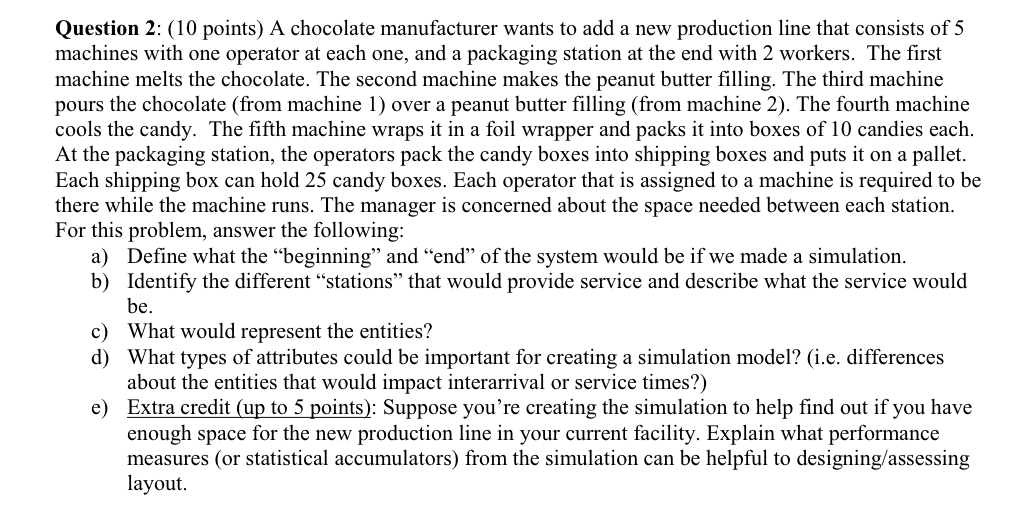

Question 2: (10 points) A chocolate manufacturer wants to add a new production line that consists of 5 machines with one operator at each one, and a packaging station at the end with 2 workers. The first machine melts the chocolate. The second machine makes the peanut butter filling. The third machine pours the chocolate (from machine 1) over a peanut butter filling (from machine 2). The fourth machine cools the candy. The fifth machine wraps it in a foil wrapper and packs it into boxes of 10 candies each. At the packaging station, the operators pack the candy boxes into shipping boxes and puts it on a pallet. Each shipping box can hold 25 candy boxes. Each operator that is assigned to a machine is required to be there while the machine runs. The manager is concerned about the space needed between each station. For this problem, answer the following: a) Define what the "beginning" and "end" of the system would be if we made a simulation. b) Identify the different "stations" that would provide service and describe what the service would be. c) What would represent the entities? d) What types of attributes could be important for creating a simulation model? (i.e. differences about the entities that would impact interarrival or service times?) e) Extra credit (up to 5 points): Suppose you're creating the simulation to help find out if you have enough space for the new production line in your current facility. Explain what performance measures (or statistical accumulators) from the simulation can be helpful to designing/assessing layout

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts