Question: Please answer the three filing questions at the end in the best of ways possible. Supplier Segmentation Hornework You just joined Intereffice & Design, Inc.

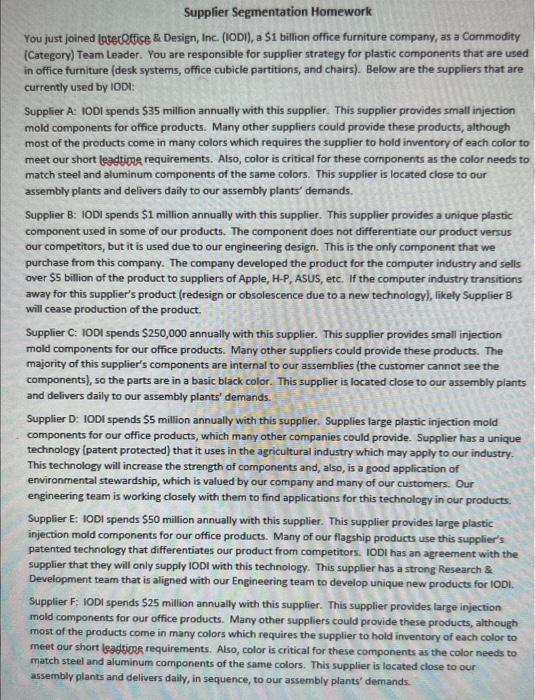

Supplier Segmentation Hornework You just joined Intereffice \& Design, Inc. (IODI), a S1 billion office furniture company, as a Commodity (Category) Team Leader. You are responsible for supplier strategy for plastic components that are used in office furniture (desk systems, office cubicle partitions, and chairs). Below are the suppliers that are currently used by IODI: Supplier A: 1001 spends $35 million annually with this supplier. This supplier provides small injection mold components for office products. Many other suppliers could provide these products, although most of the products come in many colors which requires the supplier to hold inventory of each color to meet our short leadripg requirements. Also, color is critical for these cornponents as the color needs to match steel and aluminum components of the same colors. This supplier is located close to our assembly plants and delivers daily to our assembly plants' demands. Supplier B: IODI spends $1 million annually with this supplier. This supplier provides a unique plastic component used in some of our products. The component does not differentiate our product versus our competitors, but it is used due to our engineering design. This is the only component that we purchase from this company. The company developed the product for the computer industry and sells over $5 billion of the product to suppliers of Apple, H-P, ASUS, etc. If the computer industry transitions away for this supplier's product (redesign or obsolescence due to a new technology), likely Supplier B will cease production of the product. Supplier C: IODI spends $250,000 annually with this supplier. This supplier provides small injection mold components for our office products. Many other suppliers could provide these products. The majority of this supplier's components are internal to our assemblies (the customer cannot see the components), so the parts are in a basic black color. This supplier is located close to our assembly plants and delivers daily to our assembly plants' demands. Supplier D: 100I spends $5 million annually with this supplier. Supplies large plastic injection mold components for our office products, which many other companies could provide. Supplier has a unique technology (patent protected) that it uses in the agricultural industry which may apply to our industry. This technology will increase the strength of components and, also, is a good application of environmental stewardship, which is valued by our company and many of our customers. Our engineering team is working closely with them to find applications for this technology in our products. Supplier E : IODI spends $50 million annually with this supplier. This supplier provides large plastic injection mold components for our office products. Many of our flagship products use this supplier's patented technology that differentiates our product from competitors. IODI has an agreernent with the supplier that they will only supply IODI with this technology. This supplier has a strong Research 8 . Development team that is aligned with our Engineering team to develop unique new products for IODi. Supplier F : IODI spends $25 million annually with this supplier. This supplier provides large injection mold components for our office products. Many other suppliers could provide these products, although most of the products come in many colors which requires the supplier to hold inventory of each color to meet our short leadtipe requirements. Also, color is critical for these components as the color needs to match steel and aluminum components of the same colors. This supplier is located close to our assembly plants and delivers daily, in sequence, to our assembly plants' demands. Supplier G: IODI spends $750,000 annually with this supplier. This supplier provides small injection mold components for our office products. Many other suppliers could provide these products. The majority of this supplier's components are internal to our assemblies (the customer cannot see the components), so the parts are in a basic black color. This supplier is located 10 hours (by truck) from our assembly plants. 1. Using the Kraliic Supplier Segmentation process, classify each supplier as Leverage, Strategic, Bottleneck or Non-critical. Note that a supplier cannot be in multiple classifications. 2. For each supplier, explain your reasoning for the classification selected. 3. What is your purchasing strategy for each of these suppliers? How would you design the relationship with each supplier

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts