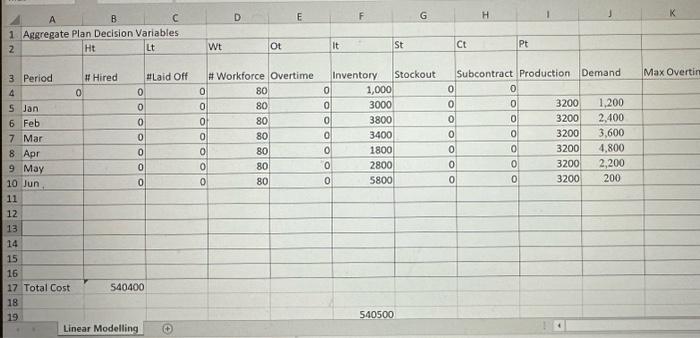

Question: Please answer these 2 questions gor me using the chart posted thank you A B C D E F G H 1. Aggregate Plan Decision

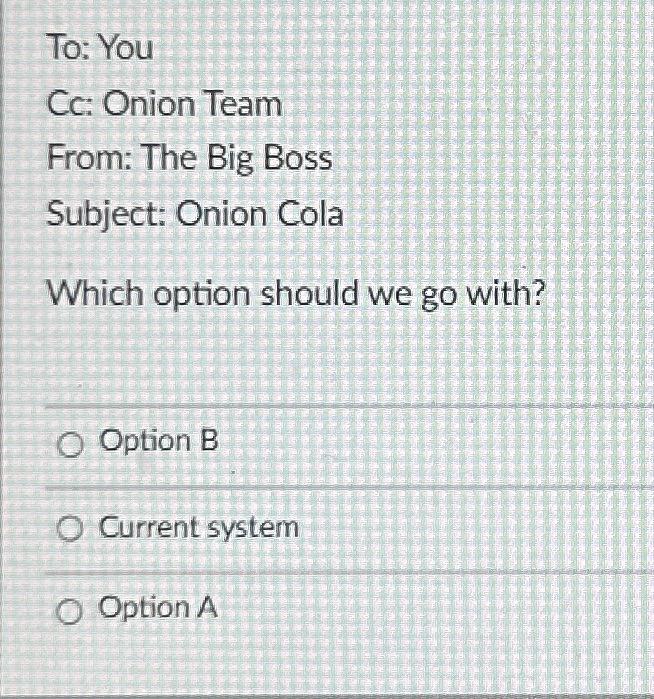

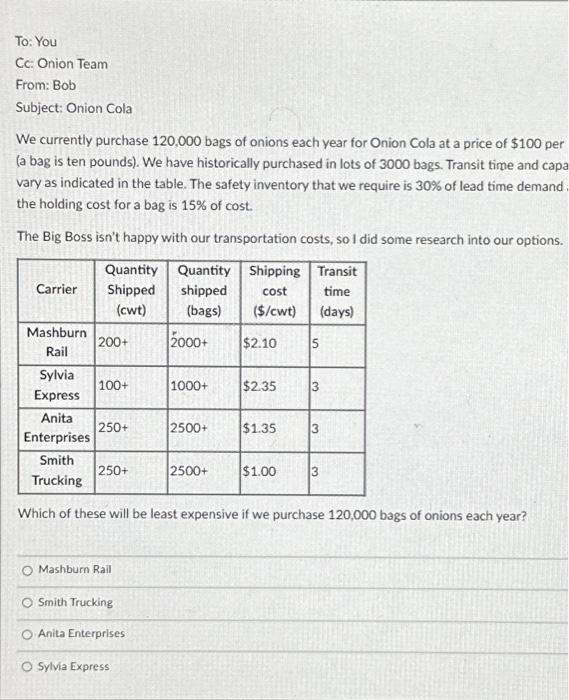

A B C D E F G H 1. Aggregate Plan Decision Variables 2 Ht Lt H. Hired "Laid Off \# Workforce Overtime Max Overtin 0 5 Jan 6 Feb 7 Mar 8 Apr 9 May 10 Jun 80 80 80 80 80 80 80 \begin{tabular}{l|l} \hline 0 & 0 \\ \hline 0 & \\ 0 & 0 \\ 0 & \\ \hline 0 & \end{tabular} \begin{tabular}{|r|r|} \hline 1,000 & Stockout \\ \hline 3000 & 0 \\ \hline 3800 & 0 \\ \hline 3400 & 0 \\ \hline 1800 & 0 \\ \hline 2800 & 0 \\ \hline 5800 & 0 \\ \hline \end{tabular} 11 12 13 14 15 16 Total Cost 540400 18 19 540500 Linear Modelling To: You Cc: Onion Team From: The Big Boss Subject: Onion Cola Which option should we go with? Option B Current system Option A To: You Cc: Onion Team From: Bob Subject: Onion Cola We currently purchase 120,000 bags of onions each year for Onion Cola at a price of $100 per (a bag is ten pounds). We have historically purchased in lots of 3000 bags. Transit time and capa vary as indicated in the table. The safety inventory that we require is 30% of lead time demand the holding cost for a bag is 15% of cost. The Big Boss isn't happy with our transportation costs, so I did some research into our options. Which of these will be least expensive if we purchase 120,000 bags of onions each year? Mashburn Rail Smith Trucking Anita Enterprises Sylvia Express

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts