Question: please answer these short questions after reading the case study. i will upvote if answers are correct! thank you. 1. How much money are the

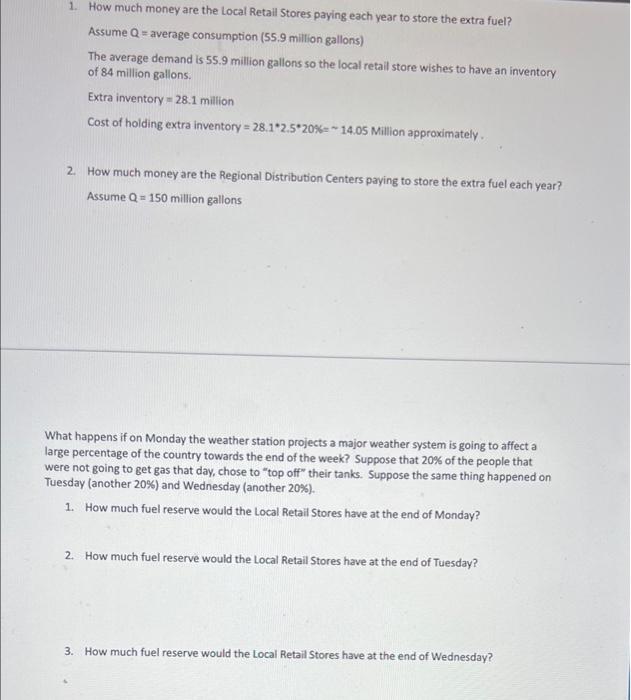

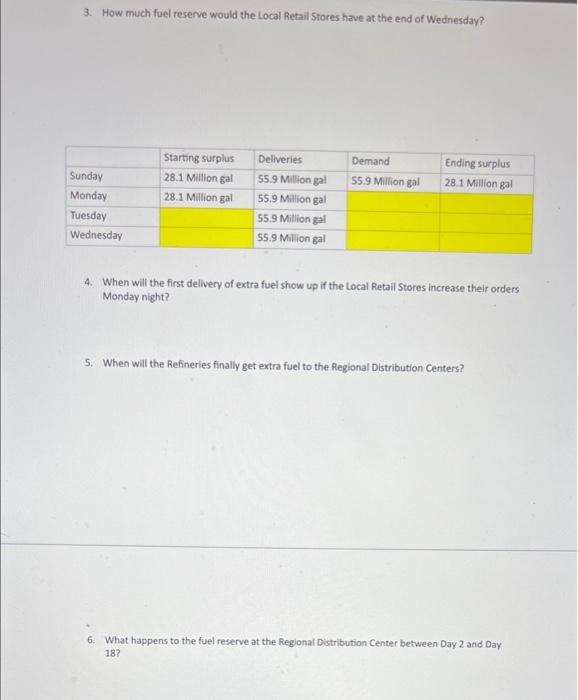

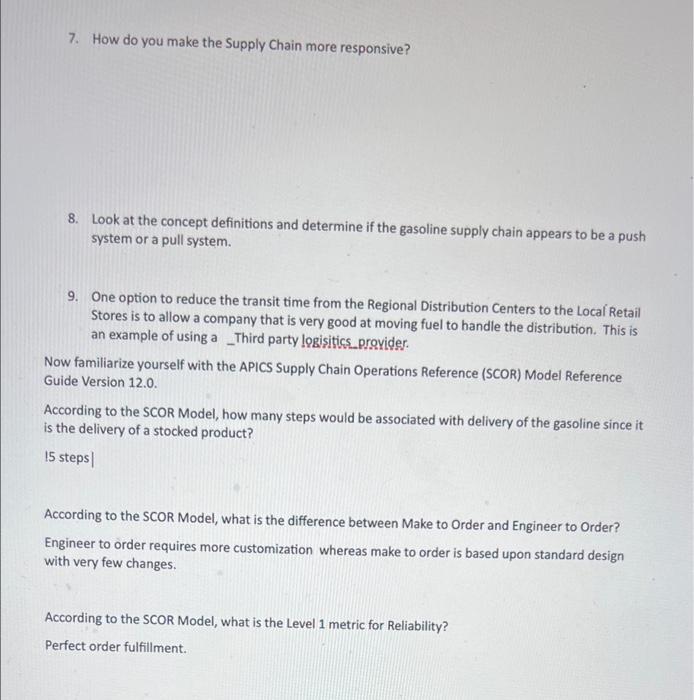

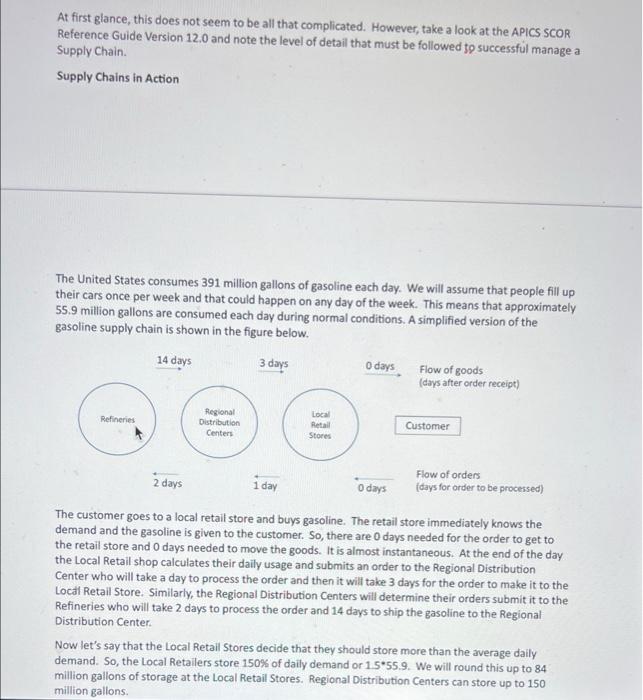

1. How much money are the local Retail Stores paying each year to store the extra fuel? Assume Q = average consumption (55.9 million gallons) The average demand is 55.9 million gallons so the local retail store wishes to have an inventory of 84 million gallons Extra inventory - 28.1 million Cost of holding extra inventory = 28.1*2.5*20%- 14.05 Million approximately 2. How much money are the Regional Distribution Centers paying to store the extra fuel each year? Assume Q = 150 million gallons What happens if on Monday the weather station projects a major weather system is going to affect a large percentage of the country towards the end of the week? Suppose that 20% of the people that were not going to get gas that day, chose to "top off their tanks. Suppose the same thing happened on Tuesday (another 20%) and Wednesday (another 20%). 1. How much fuel reserve would the Local Retail Stores have at the end of Monday? 2. How much fuel reserve would the Local Retail Stores have at the end of Tuesday? 3. How much fuel reserve would the Local Retail Stores have at the end of Wednesday? 3. How much fuel reserve would the Local Retail Stores have at the end of Wednesday? Starting surplus 28.1 Million gal 28.1 Million gal Demand 55.9 Million gal Ending surplus 28.1 Million gal Sunday Monday Tuesday Wednesday Deliveries 55.9 Million gal 55.9 Million gal 55.9 Million gal 55.9 Million gal 4. When will the first delivery of extra fuel show up if the Local Retail Stores increase their orders Monday night? 5. When will the Refineries finally get extra fuel to the Regional Distribution Centers? 6. What happens to the fuel reserve at the Regional Distribution Center between Day 2 and Day 18? 7. How do you make the Supply Chain more responsive? 8. Look at the concept definitions and determine if the gasoline supply chain appears to be a push system or a pull system. 9. One option to reduce the transit time from the Regional Distribution Centers to the Local Retail Stores is to allow a company that is very good at moving fuel to handle the distribution. This is an example of using a _Third party logisitics provider. Now familiarize yourself with the APICS Supply Chain Operations Reference (SCOR) Model Reference Guide Version 12.0. According to the SCOR Model, how many steps would be associated with delivery of the gasoline since it is the delivery of a stocked product? 15 steps According to the SCOR Model, what is the difference between Make to Order and Engineer to Order? Engineer to order requires more customization whereas make to order is based upon standard design with very few changes. According to the SCOR Model, what is the Level 1 metric for Reliability? Perfect order fulfillment. At first glance, this does not seem to be all that complicated. However, take a look at the APICS SCOR Reference Guide Version 12.0 and note the level of detail that must be followed to successful manage a Supply Chain Supply Chains in Action The United States consumes 391 million gallons of gasoline each day. We will assume that people fill up their cars once per week and that could happen on any day of the week. This means that approximately 55.9 million gallons are consumed each day during normal conditions. A simplified version of the gasoline supply chain is shown in the figure below. 14 days 3 days 0 days Flow of goods (days after order receipt) Refineries Local Regional Distribution Centers Retail Stores Customer 2 days 1 day O days Flow of orders days for order to be processed) The customer goes to a local retail store and buys gasoline. The retail store immediately knows the demand and the gasoline is given to the customer. So, there are 0 days needed for the order to get to the retail store and 0 days needed to move the goods. It is almost instantaneous. At the end of the day the Local Retail shop calculates their daily usage and submits an order to the Regional Distribution Center who will take a day to process the order and then it will take 3 days for the order to make it to the Locdl Retail Store. Similarly, the Regional Distribution Centers will determine their orders submit it to the Refineries who will take 2 days to process the order and 14 days to ship the gasoline to the Regional Distribution Center Now let's say that the Local Retail Stores decide that they should store more than the average daily demand. So, the Local Retailers store 150% of daily demand or 1.5*55.9. We will round this up to 84 million gallons of storage at the Local Retail Stores. Regional Distribution Centers can store up to 150 million gallons

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts