Question: please assist are required to evaluate two proposals for assembling a product, with an aim of assist the company to select the best method among

please assist

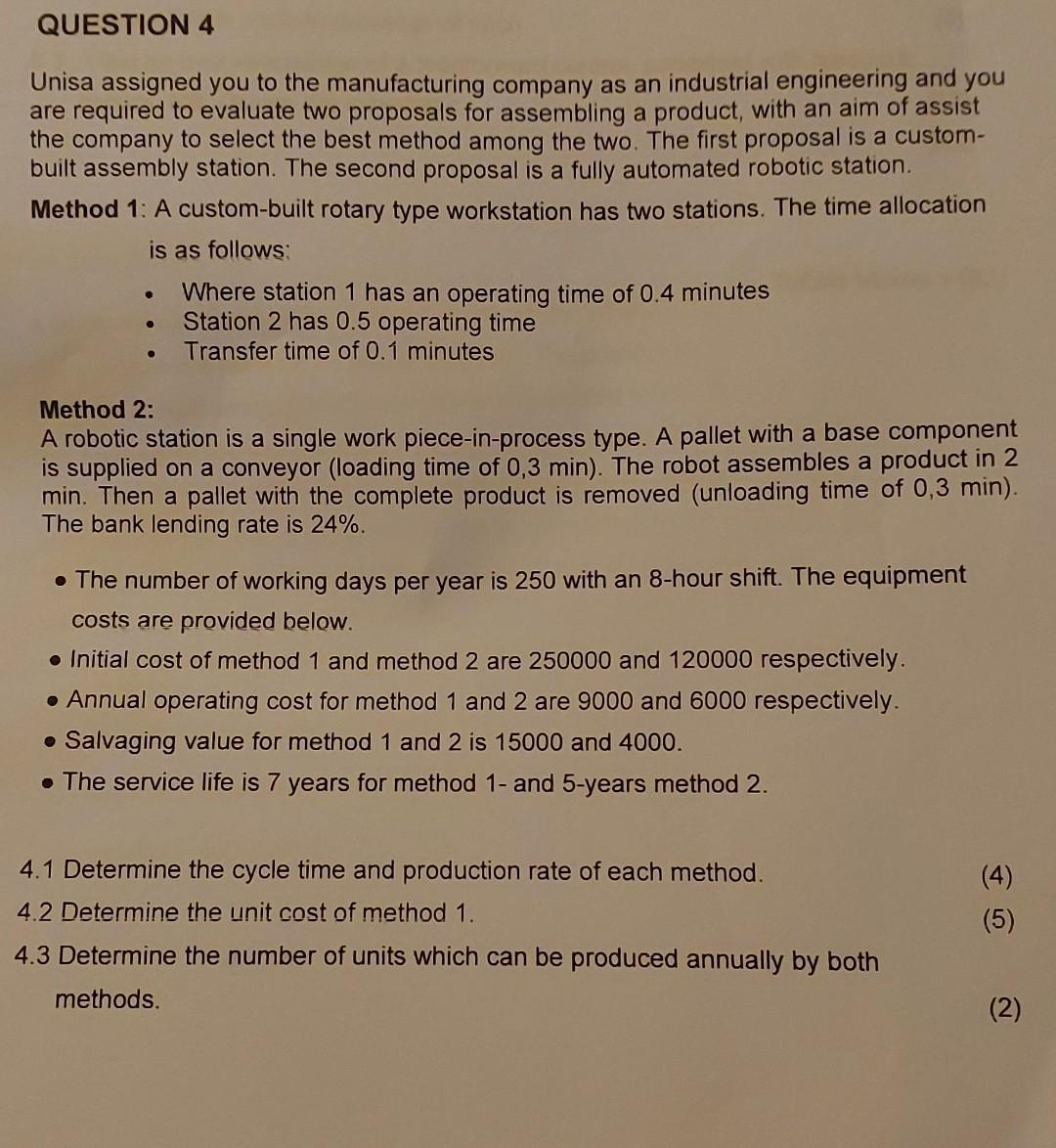

are required to evaluate two proposals for assembling a product, with an aim of assist the company to select the best method among the two. The first proposal is a custombuilt assembly station. The second proposal is a fully automated robotic station. Method 1: A custom-built rotary type workstation has two stations. The time allocation is as follows: - Where station 1 has an operating time of 0.4 minutes - Station 2 has 0.5 operating time - Transfer time of 0.1 minutes Method 2: A robotic station is a single work piece-in-process type. A pallet with a base component is supplied on a conveyor (loading time of 0,3min ). The robot assembles a product in 2 min. Then a pallet with the complete product is removed (unloading time of 0,3min ). The bank lending rate is 24%. - The number of working days per year is 250 with an 8-hour shift. The equipment costs are provided below. - Initial cost of method 1 and method 2 are 250000 and 120000 respectively. - Annual operating cost for method 1 and 2 are 9000 and 6000 respectively. - Salvaging value for method 1 and 2 is 15000 and 4000. - The service life is 7 years for method 1 - and 5 -years method 2. 4.1 Determine the cycle time and production rate of each method. (4) 4.2 Determine the unit cost of method 1. (5) 4.3 Determine the number of units which can be produced annually by both methods. (2)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts