Question: Please attach excel spreadsheet screenshots with formulas and results. A company manufactures automotive harnesses whose operator produces them at a standard rate of 20 pieces/hour.

Please attach excel spreadsheet screenshots with formulas and results.

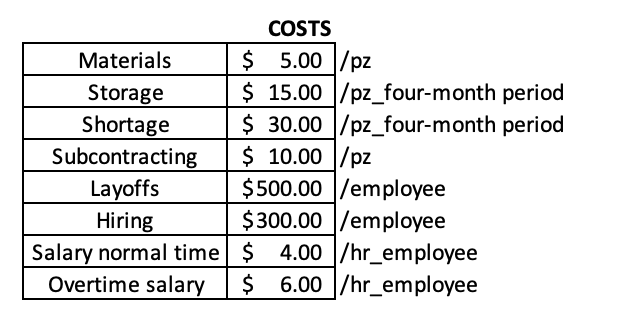

A company manufactures automotive harnesses whose operator produces them at a standard rate of 20 pieces/hour.

The manufacturing conditions would be:

- There is no inventory at the beginning of the first four-month period.

- There are no workers at the beginning of the first four-month period, being hired at the beginning of that period.

- There are a maximum of 15 workers in the four-month period.

- I will dismiss the staff at the end of the planning period.

- Priorities in supplying the demand:

1. Work 10 hours/day in normal time, at 90% productivity.

2. Work 3 hours/day in overtime, at 75% productivity.

3. Subcontract 16% of the demand when the demand is not met even when working overtime.

4. Incurring shortages with pent-up demand, but avoiding them in the last quarter.

Comparing supply strategies, determine which is more convenient in overtime: to operate with exactly the personnel assigned to the normal time or to operate considering as maximum the personnel of the normal time. Justify your answer with the possible savings.

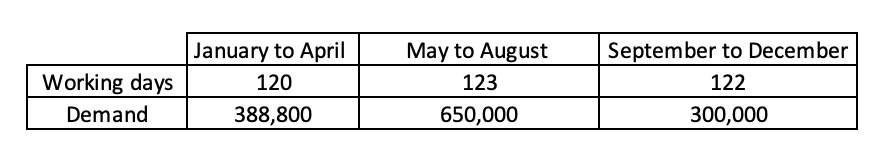

\begin{tabular}{|c|c|c|c|} \cline { 2 - 4 } \multicolumn{1}{c|}{} & January to April & May to August & September to December \\ \hline Working days & 120 & 123 & 122 \\ \hline Demand & 388,800 & 650,000 & 300,000 \\ \hline \end{tabular}

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts