Question: Please build a simulation flow chart that will find the best inventory policy. I.e. best OQ and OL pair to minimize the total cost, TC.

Please build a simulation flow chart that will find the best inventory policy. I.e. best OQ and OL pair to minimize the total cost, TC.

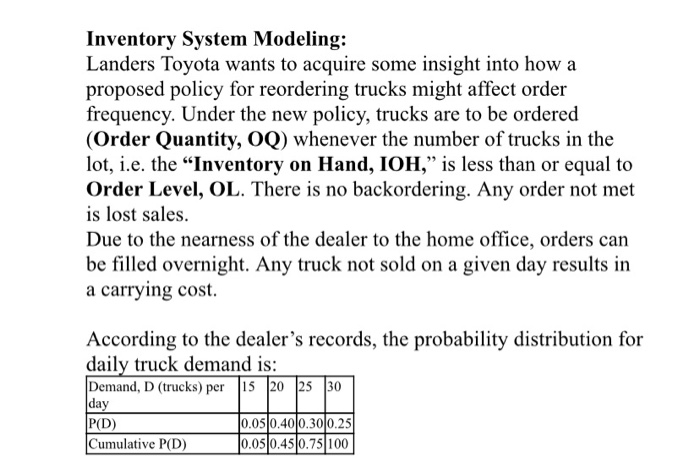

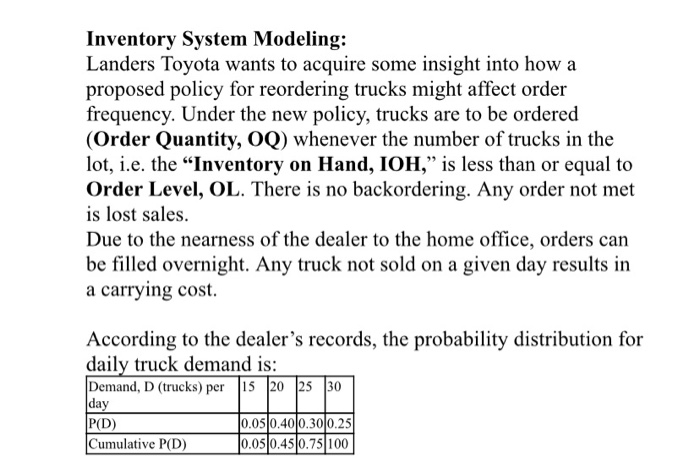

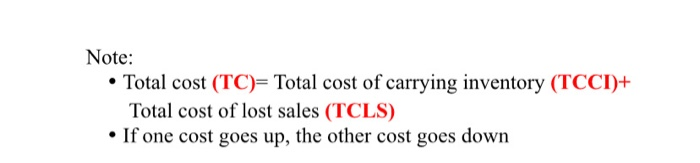

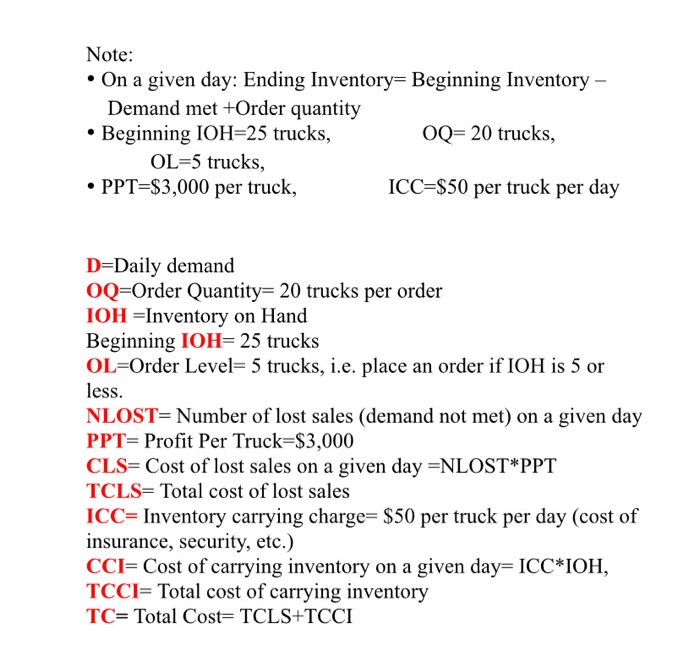

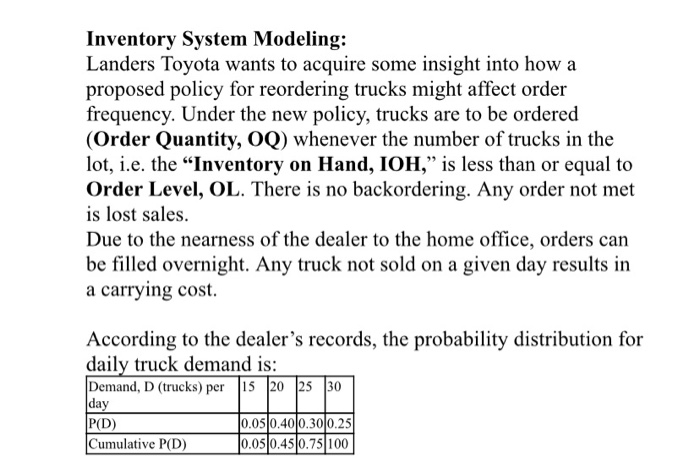

Inventory System Modeling: Landers Toyota wants to acquire some insight into how a proposed policy for reordering trucks might affect order frequency. Under the new policy, trucks are to be ordered (Order Quantity, OQ) whenever the number of trucks in the lot, i.e. the Inventory on Hand, IOH, is less than or equal to Order Level, OL. There is no backordering. Any order not met is lost sales. Due to the nearness of the dealer to the home office, orders can be filled overnight. Any truck not sold on a given day results in a carrying cost. According to the dealer's records, the probability distribution for daily truck demand is: Demand, D (trucks) per 15 20 25 30 day P(D) 0.050.400.30 0.25 Cumulative P(D) 0.050.450.75 100 Note: Total cost (TC)= Total cost of carrying inventory (TCCI)+ Total cost of lost sales (TCLS) If one cost goes up, the other cost goes down Note: On a given day: Ending Inventory=Beginning Inventory - Demand met +Order quantity Beginning IOH=25 trucks, OQ=20 trucks, OL=5 trucks, PPT=$3,000 per truck, ICC=$50 per truck per day D=Daily demand OQ=Order Quantity= 20 trucks per order IOH =Inventory on Hand Beginning IOH= 25 trucks OL=Order Level= 5 trucks, i.e. place an order if IOH is 5 or less. NLOST= Number of lost sales (demand not met) on a given day PPT=Profit Per Truck=$3,000 CLS=Cost of lost sales on a given day =NLOST* PPT TCLS= Total cost of lost sales ICC= Inventory carrying charge= $50 per truck per day (cost of insurance, security, etc.) CCI= Cost of carrying inventory on a given day= ICC*IOH, TCCI= Total cost of carrying inventory TC= Total Cost= TCLS+TCCI Inventory System Modeling: Landers Toyota wants to acquire some insight into how a proposed policy for reordering trucks might affect order frequency. Under the new policy, trucks are to be ordered (Order Quantity, OQ) whenever the number of trucks in the lot, i.e. the Inventory on Hand, IOH, is less than or equal to Order Level, OL. There is no backordering. Any order not met is lost sales. Due to the nearness of the dealer to the home office, orders can be filled overnight. Any truck not sold on a given day results in a carrying cost. According to the dealer's records, the probability distribution for daily truck demand is: Demand, D (trucks) per 15 20 25 30 day P(D) 0.050.400.30 0.25 Cumulative P(D) 0.050.450.75 100 Note: Total cost (TC)= Total cost of carrying inventory (TCCI)+ Total cost of lost sales (TCLS) If one cost goes up, the other cost goes down Note: On a given day: Ending Inventory=Beginning Inventory - Demand met +Order quantity Beginning IOH=25 trucks, OQ=20 trucks, OL=5 trucks, PPT=$3,000 per truck, ICC=$50 per truck per day D=Daily demand OQ=Order Quantity= 20 trucks per order IOH =Inventory on Hand Beginning IOH= 25 trucks OL=Order Level= 5 trucks, i.e. place an order if IOH is 5 or less. NLOST= Number of lost sales (demand not met) on a given day PPT=Profit Per Truck=$3,000 CLS=Cost of lost sales on a given day =NLOST* PPT TCLS= Total cost of lost sales ICC= Inventory carrying charge= $50 per truck per day (cost of insurance, security, etc.) CCI= Cost of carrying inventory on a given day= ICC*IOH, TCCI= Total cost of carrying inventory TC= Total Cost= TCLS+TCCI