Question: Please can you complete solving it I really need it I should submit it tomorrow ! can you please solve it i finsh only the

Please can you complete solving it I really need it I should submit it tomorrow !

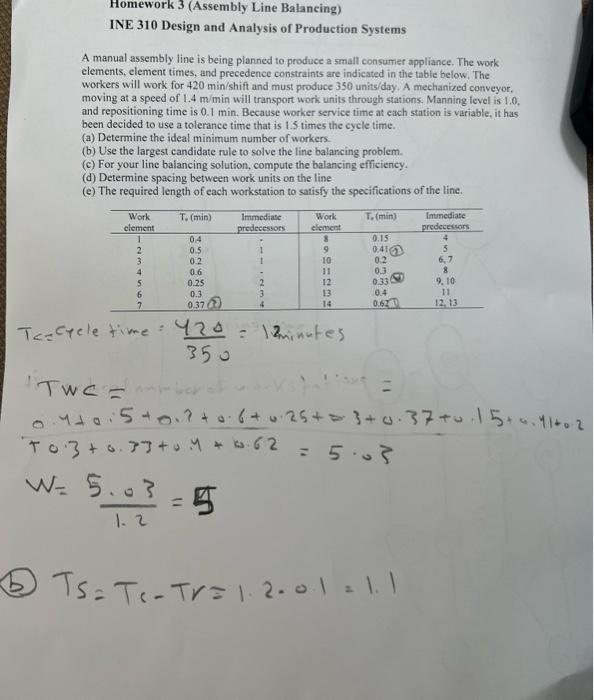

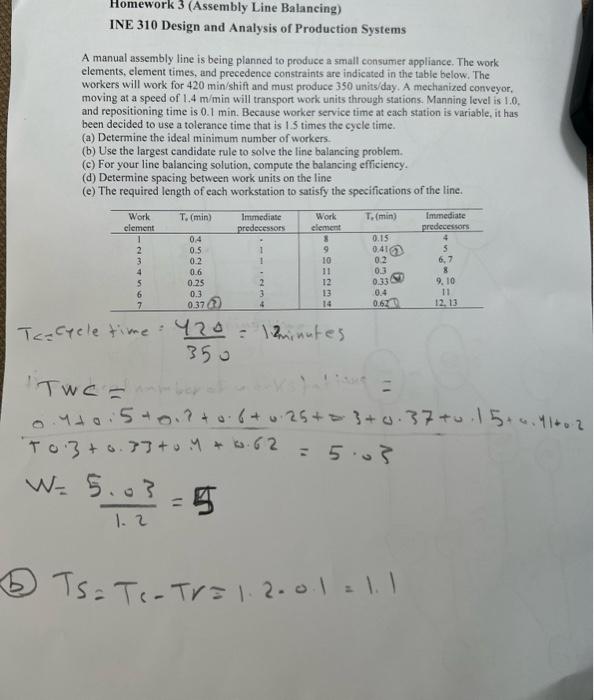

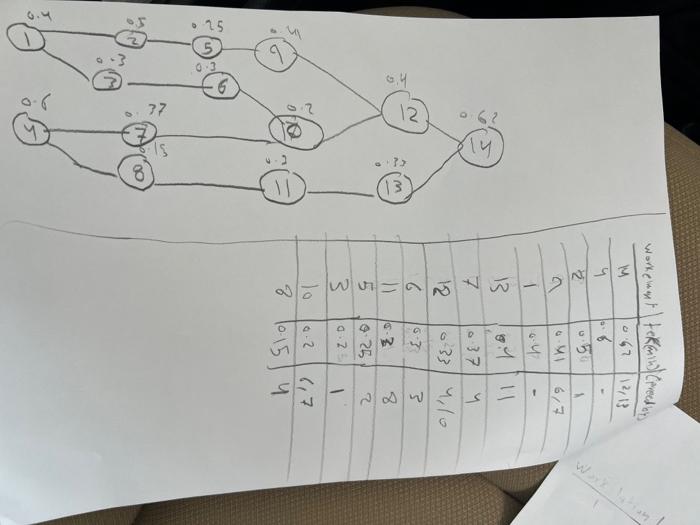

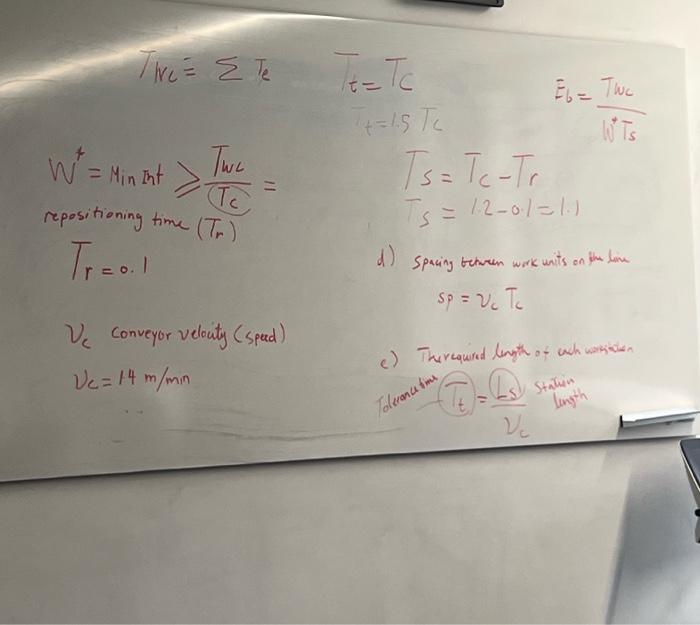

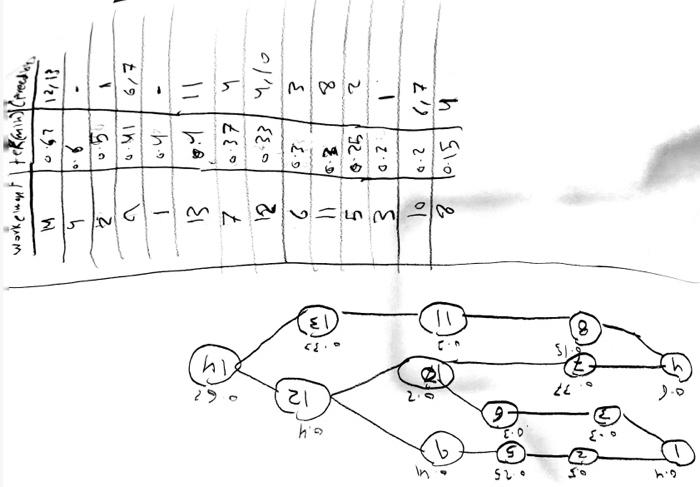

A manual assembly line is being planned to produce a smalt consumer appliance. The work elements, element times, and precedence constraints are indicated in the table below. The workers will work for 420 min/shift and must produce 350 units/day. A mechanized conveyor. workers will work for 420min/shift and must produce 350 units/day. A mechanized conveyor, and repositioning time is 0.1min. Because worker service time at each station is variable, it has (a) Determine the ideal minimum number of workers. (b) Use the largest candidate rule to solve the line balancing problem. (c) For your line balancing solution, compute the balancing efficiency. (d) Dhe required length of each workstation to satisfy the tion to satisfy the specifications of the line. Tc=crcletime=350420=12minutesTWC=0.4+0.5+0.7+0.6+0.25+=3+0.37+0.15+0.0T0.3+0.37+0.4+0.62=5.03W=1.25.03=5 () Ts=TsTr=120.1=1.1 A manual assembly line is being planned to produce a smalt consumer appliance. The work elements, element times, and precedence constraints are indicated in the table below. The workers will work for 420 min/shift and must produce 350 units/day. A mechanized conveyor. workers will work for 420min/shift and must produce 350 units/day. A mechanized conveyor, and repositioning time is 0.1min. Because worker service time at each station is variable, it has (a) Determine the ideal minimum number of workers. (b) Use the largest candidate rule to solve the line balancing problem. (c) For your line balancing solution, compute the balancing efficiency. (d) Dhe required length of each workstation to satisfy the tion to satisfy the specifications of the line. Tc=crcletime=350420=12minutesTWC=0.4+0.5+0.7+0.6+0.25+=3+0.37+0.15+0.0T0.3+0.37+0.4+0.62=5.03W=1.25.03=5 () Ts=TsTr=120.1=1.1 W+=MinihtTcTwc=repositioningtime(Tr)TS=TcTrTS=1.20.1=1.1Tr=0.1sp=vcTcVc=14m/min A manual assembly line is being planned to produce a small consumer appliance. The work elements, element times, and precedence constraints are indicated in the table below. The workers will work for 420min/shift and must produce 350 units/day. A mechanized conveyor. moving at a speed of 1.4m/min will transport work units through stations. Manning level is 1.0 , and repositioning time is 0.1min. Because worker service time at each station is variable, it has been decided to use a tolerance time that is 1.5 times the cycle time. (a) Determine the ideal minimum number of workers. (b) Use the largest candidate rule to solve the line balancing problem. (c) For your line balancing solution, compute the balancing efficiency. (d) Determine spacing between work units on the line (e) The required length of each workstation to satisfy the specifications of the line. Tc==reletime=350420=1minutesTWCT,rus=0.4+0.5+0.2+0.60.25+03+0.37+0.15+.T0.3+0.37+0.4+0.62=5.03W=1.25.03=5(b)TS=TcTr=1.20.1=1.1

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts