Question: Please complete Q4. No extra information needed thabk you BlueBolt Bottlers has a bottle-filling process with a mean value of 62 ounces and a standard

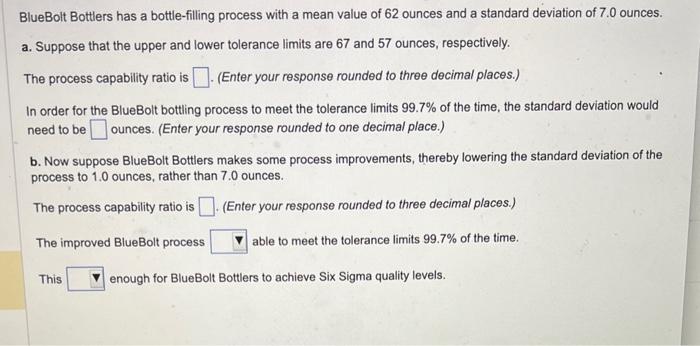

BlueBolt Bottlers has a bottle-filling process with a mean value of 62 ounces and a standard deviation of 7.0 ounces. a. Suppose that the upper and lower tolerance limits are 67 and 57 ounces, respectively. The process capability ratio is ( Enter your response rounded to three decimal places.) In order for the BlueBolt bottling process to meet the tolerance limits 99.7% of the time, the standard deviation would need to be ounces. (Enter your response rounded to one decimal place.) b. Now suppose BlueBolt Bottlers makes some process improvements, thereby lowering the standard deviation of the process to 1.0 ounces, rather than 7.0 ounces. The process capability ratio is (Enter your response rounded to three decimal places.) The improved BlueBolt process able to meet the tolerance limits 99.7% of the time. This enough for BlueBolt Bottlers to achieve Six Sigma quality levels

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts