Question: Please do it without using the the solver thanks PK Village purchases energy drinks from a supplier in Port St. Lucie. Demand for this product

Please do it without using the the solver thanks

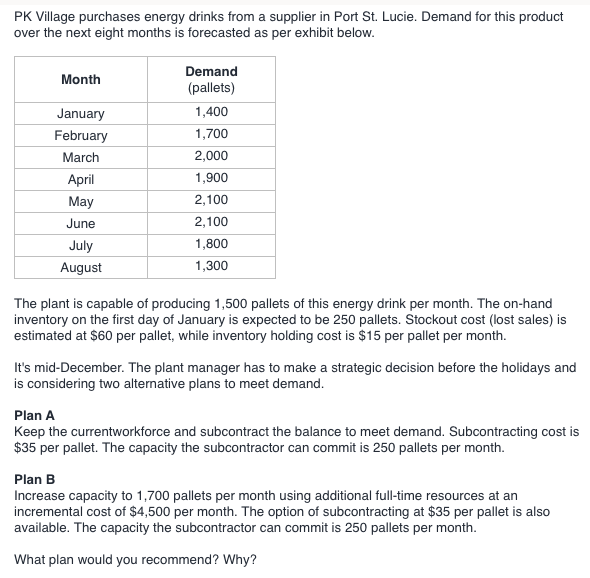

PK Village purchases energy drinks from a supplier in Port St. Lucie. Demand for this product over the next eight months is forecasted as per exhibit below. Month January February March April May June July August Demand (pallets) 1,400 1,700 2,000 1,900 2,100 2,100 1,800 1,300 The plant is capable of producing 1,500 pallets of this energy drink per month. The on-hand inventory on the first day of January is expected to be 250 pallets. Stockout cost (lost sales) is estimated at $60 per pallet, while inventory holding cost is $15 per pallet per month. It's mid-December. The plant manager has to make a strategic decision before the holidays and is considering two alternative plans to meet demand. Plan A Keep the currentworkforce and subcontract the balance to meet demand. Subcontracting cost is $35 per pallet. The capacity the subcontractor can commit is 250 pallets per month. Plan B Increase capacity to 1,700 pallets per month using additional full-time resources at an incremental cost of $4,500 per month. The option of subcontracting at $35 per pallet is also available. The capacity the subcontractor can commit is 250 pallets per month. What plan would you recommend? WhyStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock