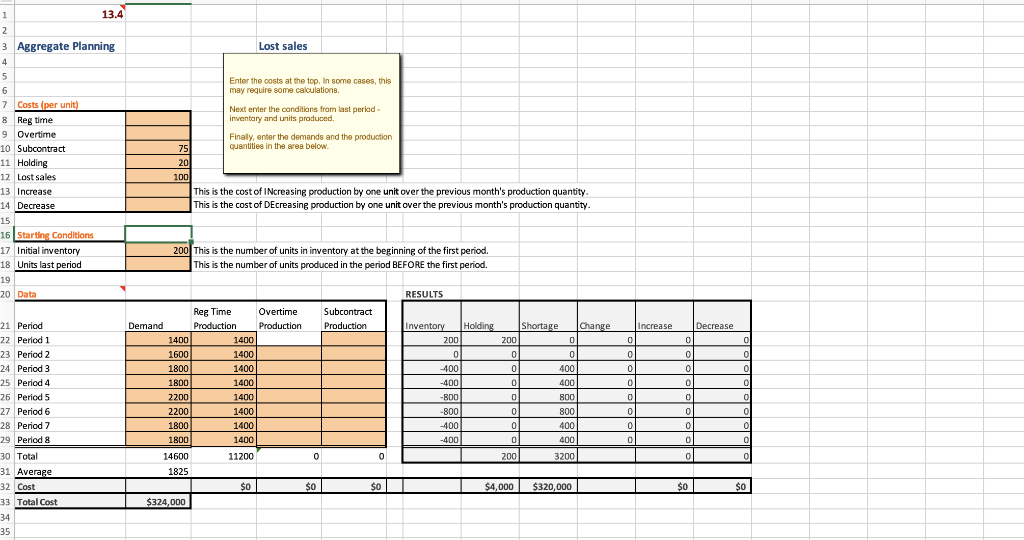

Question: Please do just 13.4 for me. Answer is supposed to be 244,000. please tell me what I did wrong and what inputs are supposed to

Please do just 13.4 for me. Answer is supposed to be 244,000. please tell me what I did wrong and what inputs are supposed to be. im so confused

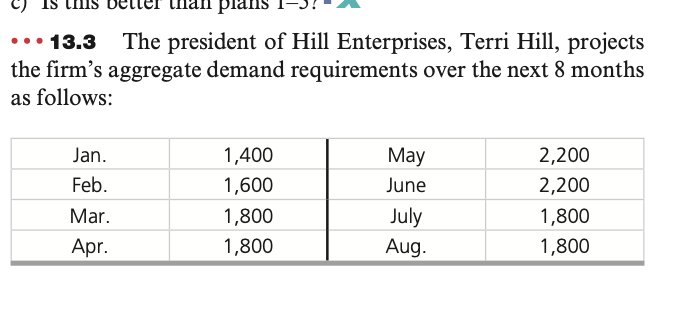

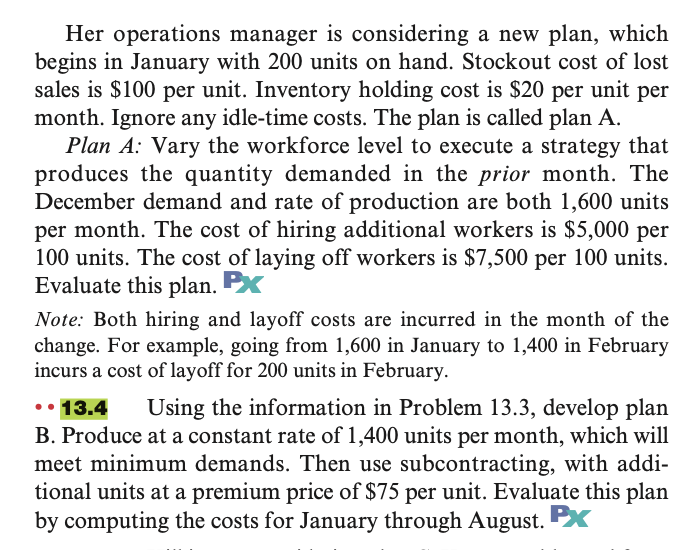

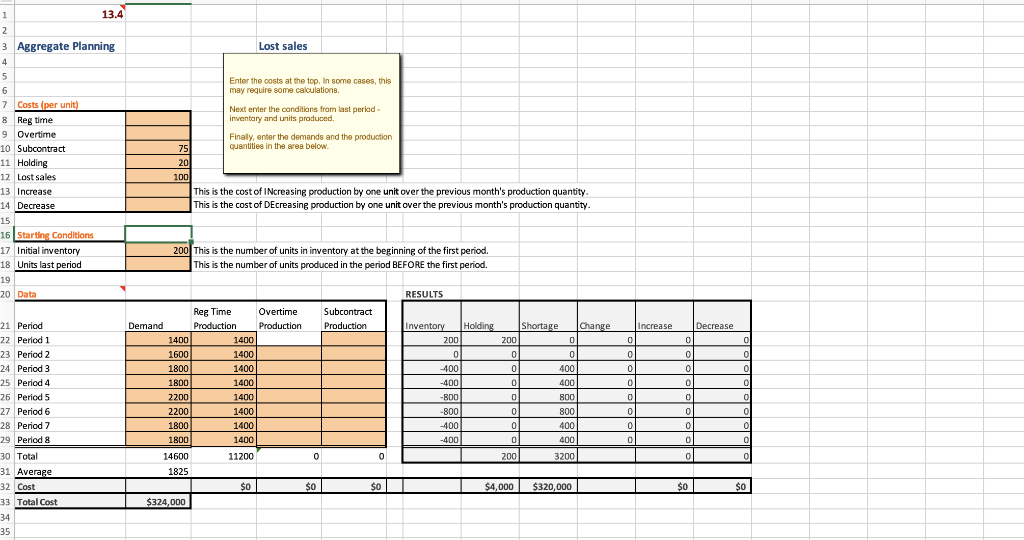

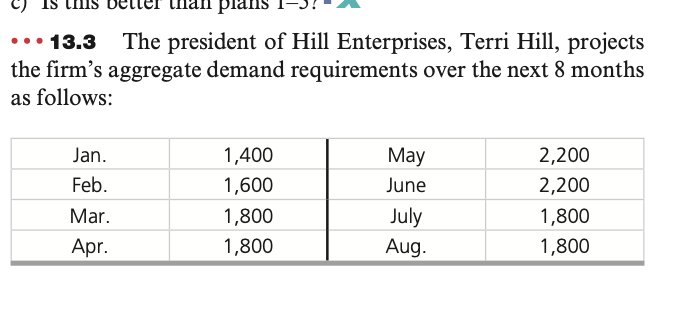

plans 13.3 The president of Hill Enterprises, Terri Hill, projects the firm's aggregate demand requirements over the next 8 months as follows: Jan. Feb. Mar. Apr. 1,400 1,600 1,800 1,800 May June July Aug. 2,200 2,200 1,800 1,800 Her operations manager is considering a new plan, which begins in January with 200 units on hand. Stockout cost of lost sales is $100 per unit. Inventory holding cost is $20 per unit per month. Ignore any idle-time costs. The plan is called plan A. Plan A: Vary the workforce level to execute a strategy that produces the quantity demanded in the prior month. The December demand and rate of production are both 1,600 units per month. The cost of hiring additional workers is $5,000 per 100 units. The cost of laying off workers is $7,500 per 100 units. Evaluate this plan. PX Note: Both hiring and layoff costs are incurred in the month of the change. For example, going from 1,600 in January to 1,400 in February incurs a cost of layoff for 200 units in February. 13.4 Using the information in Problem 13.3, develop plan B. Produce at a constant rate of 1,400 units per month, which will meet minimum demands. Then use subcontracting, with addi- tional units at a premium price of $75 per unit. Evaluate this plan by computing the costs for January through August. Px 1 13.4 2 3 Aggregate Planning Lost sales 4 Enter the costs at the top. In some cases, this may require some calculations, 5 6 7 Costs (per unit) 8 Reg time 9 Overtime 10 Subcontract 11 Holding 12 Lost sales 13 Increase 14 Decrease 15 16 Starting Conditions 17 Initial inventory 18 Units last period 19 20 Data Next enter the conditions from last period inventary and units produced Finally, enter the demands and the production 75 quantities in the area below. 20 100 This is the cost of Increasing production by one unit over the previous month's production quantity This is the cost of Decreasing production by one unit over the previous month's production quantity 200 This is the number of units in inventory at the beginning of the first period This is the number of units produced in the period BEFORE the first period. RESULTS Subcontract Production Demand Change Increase Decrease Shortage 200 0 0 0 0 Reg Time Overtime Production Production 1400 1400 1600 1400 1800 14001 1800 1400 0 0 0 0 0 0 Inventory Holding 200 0 -400 -400 -800 -800 -400 0 0 0 0 0 0 0 0 400 400 800 800 400 1400 0 0 0 0 0 0 0 2200 2200 1800 1800 1400 1400 1400 0 21 Period 22 Period 1 23 Period 2 24 Period 3 25 Period 4 26 Period 5 27 Period 6 28 Period 7 29 Period 8 30 Total 31 Average 32 Cost 33 Total Cost 34 35 0 0 0 0 0 0 0 -400 0 400 0 0 11200 0 0 200 3200 0 0 14600 1825 $ so $0 o $0 $4,000 $320,000 $0 $0 $324,000