Question: PLEASE DO NOT COPY THE ALREADY AVAILABLE ANSWER ON CHEGG!,THE ANSWER IS INCORRECT.Thank you EACHER PRACTICE ANOTHER The Ace Manufacturing Company has orders for three

PLEASE DO NOT COPY THE ALREADY AVAILABLE ANSWER ON CHEGG!,THE ANSWER IS INCORRECT.Thank you

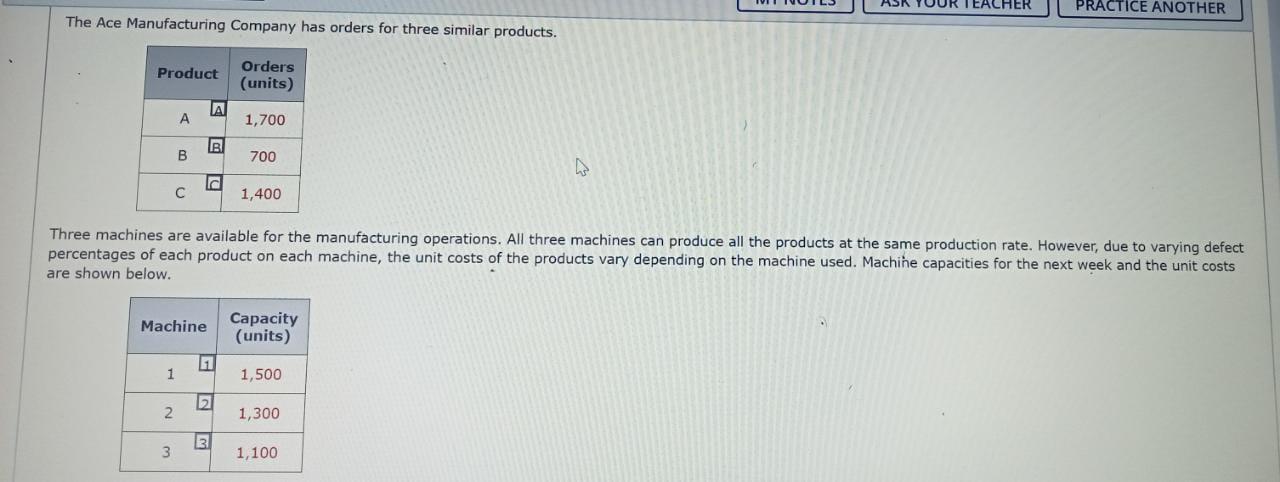

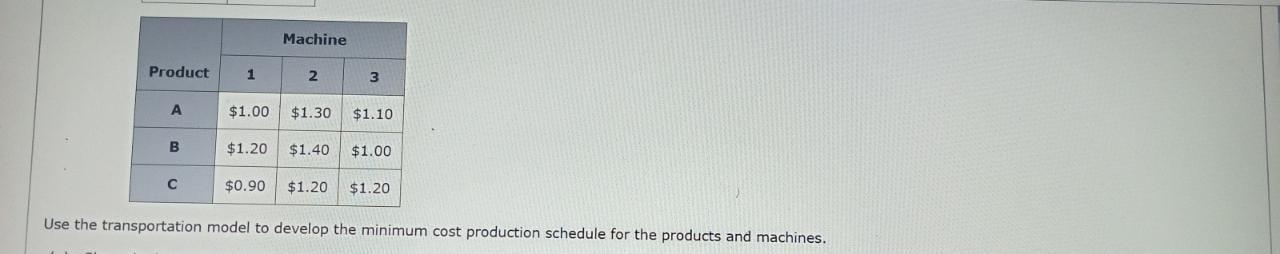

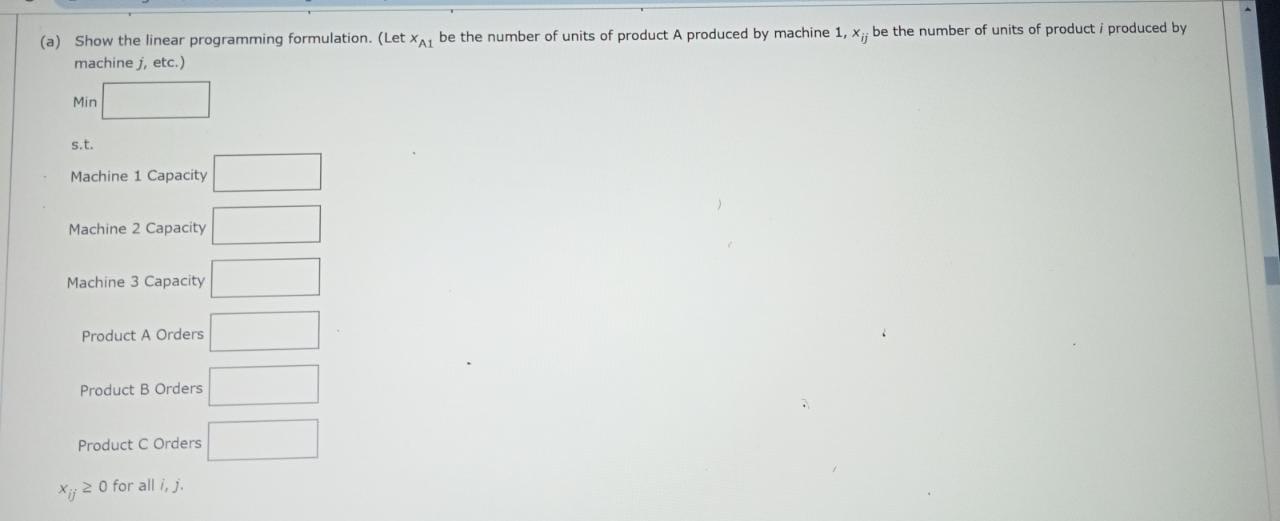

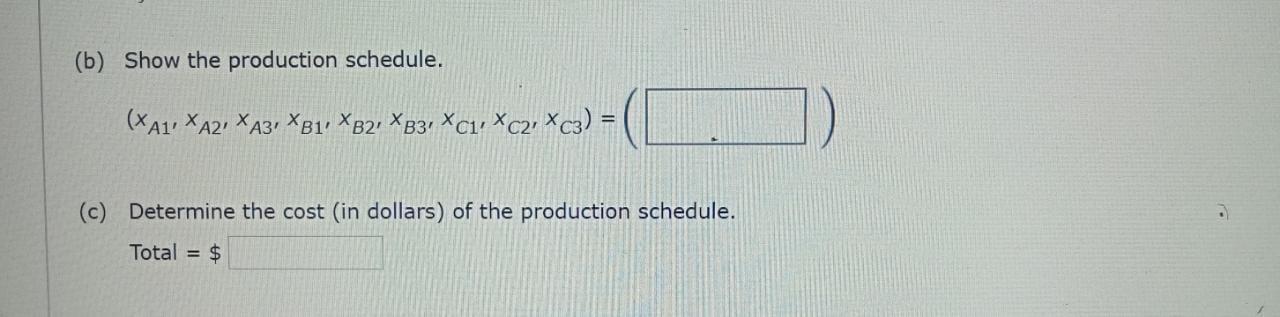

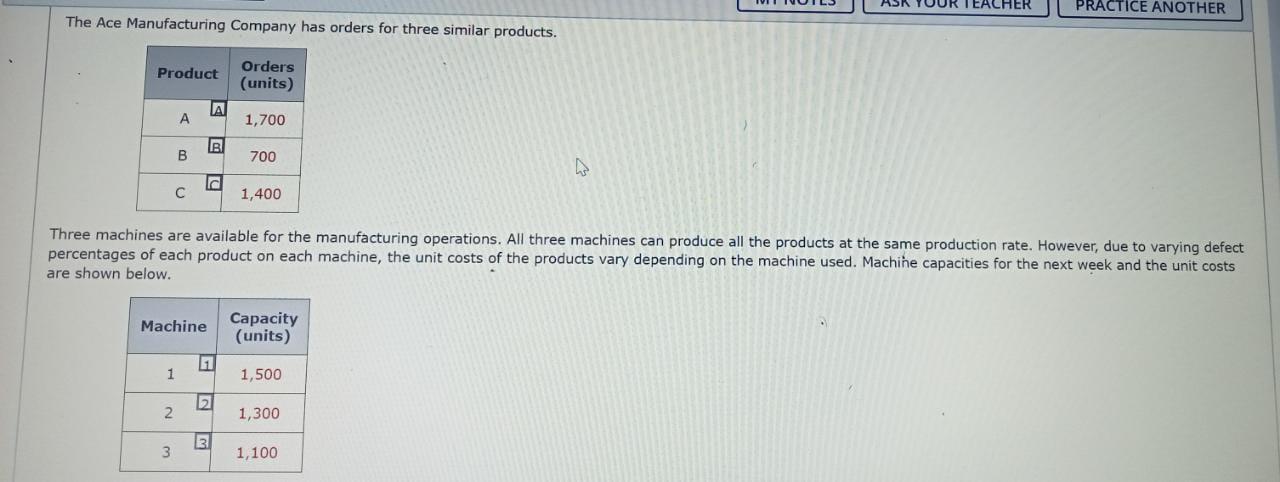

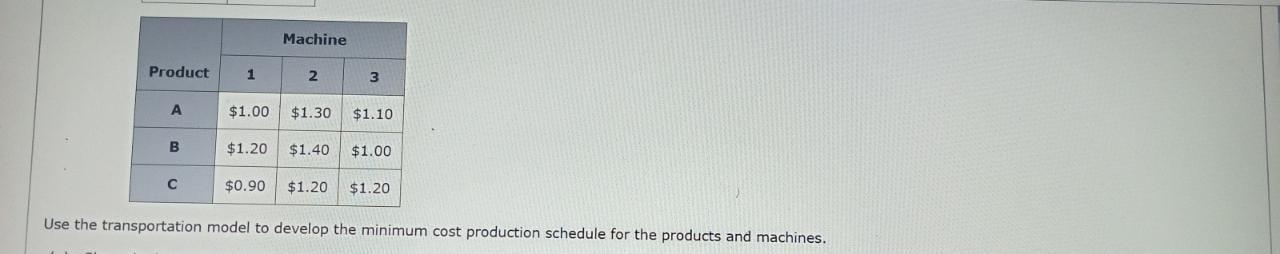

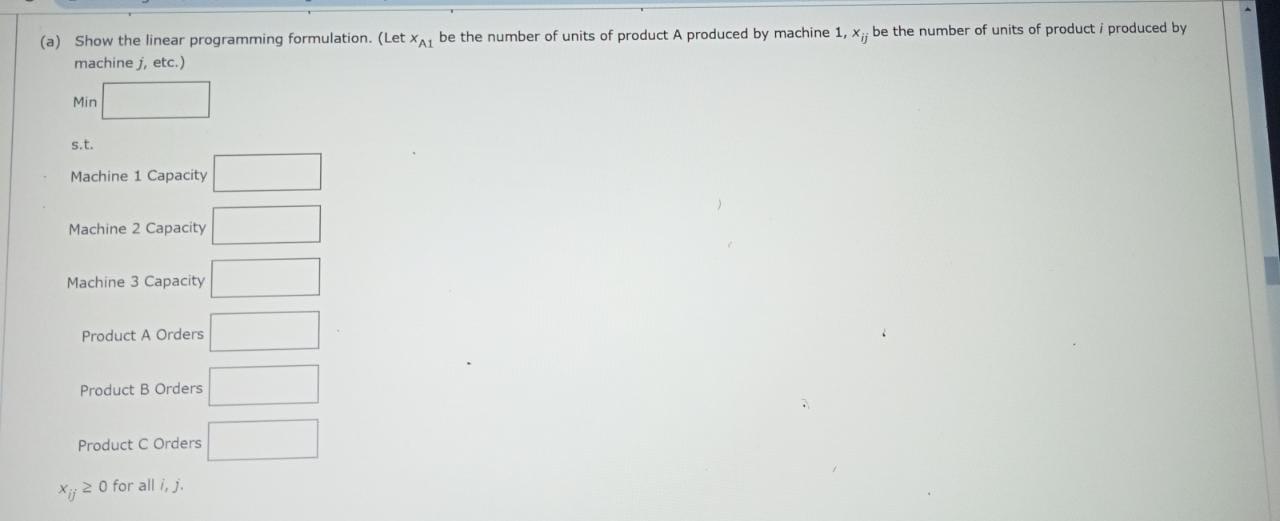

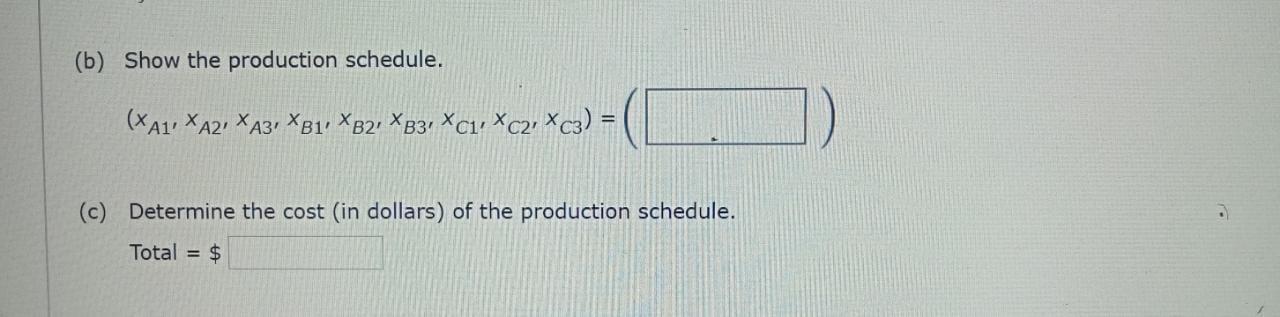

EACHER PRACTICE ANOTHER The Ace Manufacturing Company has orders for three similar products. Product Orders (units) A 1,700 B B 700 c 1,400 Three machines are available for the manufacturing operations. All three machines can produce all the products at the same production rate. However, due to varying defect percentages of each product on each machine, the unit costs of the products vary depending on the machine used. Machine capacities for the next week and the unit costs are shown below. Machine Capacity (units) 1 1,500 2 2 1,300 B 3 1,100 Machine Product 1 2 3 $1.00 $1.30 $1.10 B $1.20 $1.40 $1.00 $0.90 $1.20 $1.20 Use the transportation model to develop the minimum cost production schedule for the products and machines. (a) Show the linear programming formulation. (Let XA1 be the number of units of product A produced by machine 1, X;; be the number of units of product i produced by machine J, etc.) Min s.t. Machine 1 Capacity Machine 2 Capacity Machine 3 Capacity Product A Orders Product B Orders Product C Orders X;; 2 0 for all /,; (b) Show the production schedule. (XA1, XA2, XA3, XB1, XB2, XB3, Xc1, Xc2, Xc3) = (c) Determine the cost (in dollars) of the production schedule. Total = $