Question: please do not solve it in excel. Question 13 FlexSteal, marketed as a miracle brush-on sealant and baldness cure, is manufactured at three plants to

please do not solve it in excel.

please do not solve it in excel.

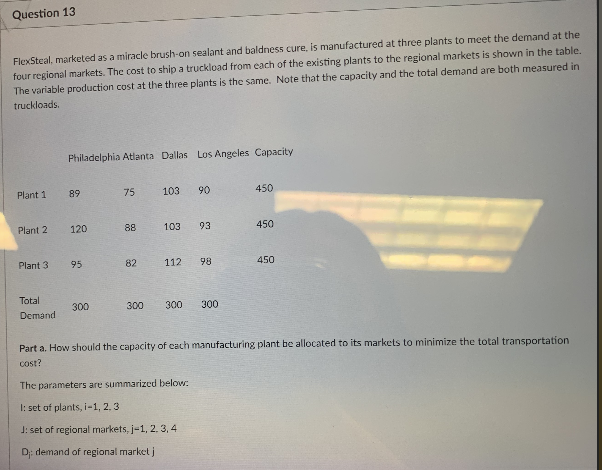

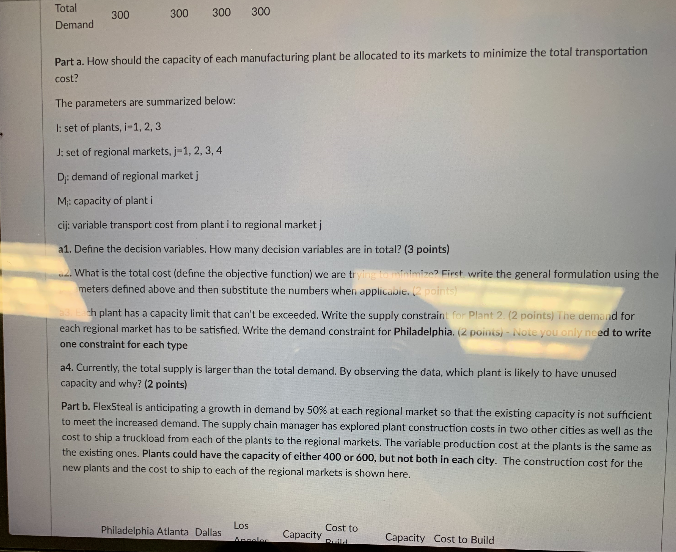

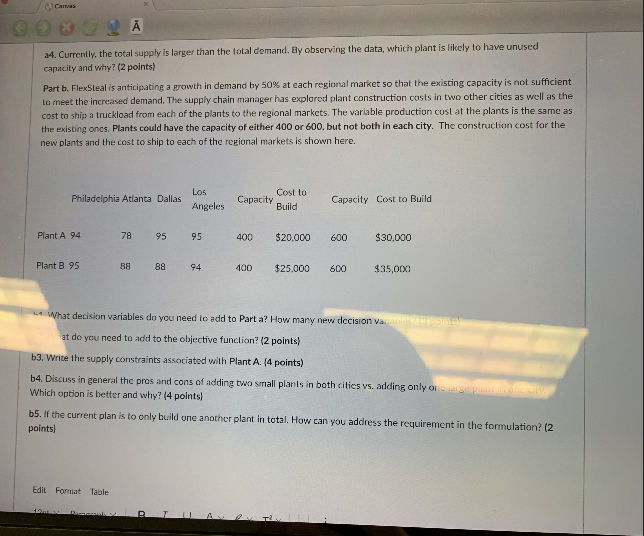

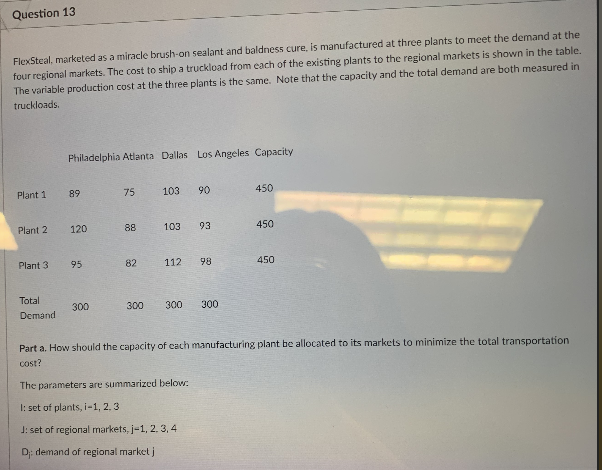

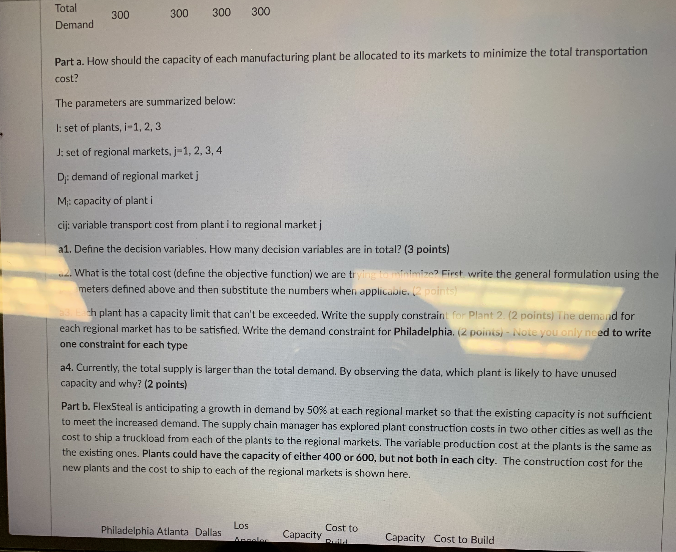

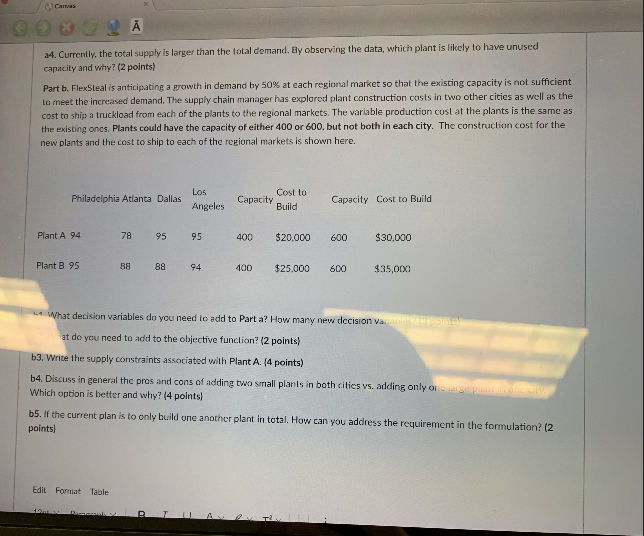

Question 13 FlexSteal, marketed as a miracle brush-on sealant and baldness cure, is manufactured at three plants to meet the demand at the four regional markets. The cost to ship a truckload from each of the existing plants to the regional markets is shown in the table. The variable production cost at the three plants is the same. Note that the capacity and the total demand are both measured in truckloads. Philadelphia Atlanta Dallas Los Angeles Capacity Plant 1 89 75 103 90 450 120 88 103 93 450 Plant 2 95 82 Plant 3 112 98 450 Total Demand 300 300 300 300 Part a. How should the capacity of each manufacturing plant be allocated to its markets to minimize the total transportation COST? The parameters are summarized below: 1: set of plants, 1-1, 2.3 1: set of regional markets, 1-1, 2.3.4 Di demand of regional marketi Total Demand 300 300 300 300 Part a. How should the capacity of each manufacturing plant be allocated to its markets to minimize the total transportation cost? The parameters are summarized below: 1: set of plants, 1-1,2,3 J: set of regional markets, j-1,2,3,4 D demand of regional market i Mi capacity of planti cij: variable transport cost from plant i to regional market i a1. Define the decision variables. How many decision variables are in total? (3 points) What is the total cost define the objective function, we are trying to minimiza? First write the general formulation using the meters defined above and then substitute the numbers when applicable. 2 points Eth plant has a capacity limit that can't be exceeded. Write the supply constraint for Plant 2. (2 points) The demand for each regional market has to be satisfied. Write the demand constraint for Philadelphia. (2 points) - Note you only need to write one constraint for each type a4. Currently, the total supply is larger than the total demand. By observing the data, which plant is likely to have unused capacity and why? (2 points) Part b. FlexSteal is anticipating a growth in demand by 50% at each regional market so that the existing capacity is not sufficient to meet the increased demand. The supply chain manager has explored plant construction costs in two other cities as well as the cost to ship a truckload from each of the plants to the regional markets. The variable production cost at the plants is the same as the existing ones. Plants could have the capacity of either 400 or 600, but not both in each city. The construction cost for the new plants and the cost to ship to each of the regional markets is shown here. Philadelphia Atlanta Dallas Los Cost to Capacity RL Capacity Cost to Build Canvas 24. Currently, the total supply is larger than the total demand. By observing the data, which plant is likely to have unused capacity and why? (2 points) Part b. FlexSteal is anticipating a growth in demand by 50% at each regional market so that the existing capacity is not sufficient to meet the increased demand. The supply chain manager has explored plant construction costs in two other cities as well as the cost to ship a truckload from each of the plants to the regional markets. The variable production cost at the plants is the same as the existing ones. Plants could have the capacity of either 400 or 600, but not both in each city. The construction cost for the new plants and the cost to ship to each of the regional markets is shown here. Philadelphia Atlanta Dallas Los Angeles Cost to Capacity Build Capacity Cost to Build Plant A 94 78 95 95 400 $20,000 600 $30,000 Plant B 95 Ra 88 94 400 $25.000 600 $35,000 What decision variables do you need to add to Parta? How many new decision van at do you need to add to the objective function? (2 points) b3. Write the supply constraints associated with Plant A. (4 points) 64. Discuss in general the pros and cons of adding two small plants in both dities vs. adding only on e pension Which option is better and why? (4 points bs. If the current plan is to only build one another plant in total. How can you address the requirement in the formulation? (2 points) Edit Format Table . Question 13 FlexSteal, marketed as a miracle brush-on sealant and baldness cure, is manufactured at three plants to meet the demand at the four regional markets. The cost to ship a truckload from each of the existing plants to the regional markets is shown in the table. The variable production cost at the three plants is the same. Note that the capacity and the total demand are both measured in truckloads. Philadelphia Atlanta Dallas Los Angeles Capacity Plant 1 89 75 103 90 450 120 88 103 93 450 Plant 2 95 82 Plant 3 112 98 450 Total Demand 300 300 300 300 Part a. How should the capacity of each manufacturing plant be allocated to its markets to minimize the total transportation COST? The parameters are summarized below: 1: set of plants, 1-1, 2.3 1: set of regional markets, 1-1, 2.3.4 Di demand of regional marketi Total Demand 300 300 300 300 Part a. How should the capacity of each manufacturing plant be allocated to its markets to minimize the total transportation cost? The parameters are summarized below: 1: set of plants, 1-1,2,3 J: set of regional markets, j-1,2,3,4 D demand of regional market i Mi capacity of planti cij: variable transport cost from plant i to regional market i a1. Define the decision variables. How many decision variables are in total? (3 points) What is the total cost define the objective function, we are trying to minimiza? First write the general formulation using the meters defined above and then substitute the numbers when applicable. 2 points Eth plant has a capacity limit that can't be exceeded. Write the supply constraint for Plant 2. (2 points) The demand for each regional market has to be satisfied. Write the demand constraint for Philadelphia. (2 points) - Note you only need to write one constraint for each type a4. Currently, the total supply is larger than the total demand. By observing the data, which plant is likely to have unused capacity and why? (2 points) Part b. FlexSteal is anticipating a growth in demand by 50% at each regional market so that the existing capacity is not sufficient to meet the increased demand. The supply chain manager has explored plant construction costs in two other cities as well as the cost to ship a truckload from each of the plants to the regional markets. The variable production cost at the plants is the same as the existing ones. Plants could have the capacity of either 400 or 600, but not both in each city. The construction cost for the new plants and the cost to ship to each of the regional markets is shown here. Philadelphia Atlanta Dallas Los Cost to Capacity RL Capacity Cost to Build Canvas 24. Currently, the total supply is larger than the total demand. By observing the data, which plant is likely to have unused capacity and why? (2 points) Part b. FlexSteal is anticipating a growth in demand by 50% at each regional market so that the existing capacity is not sufficient to meet the increased demand. The supply chain manager has explored plant construction costs in two other cities as well as the cost to ship a truckload from each of the plants to the regional markets. The variable production cost at the plants is the same as the existing ones. Plants could have the capacity of either 400 or 600, but not both in each city. The construction cost for the new plants and the cost to ship to each of the regional markets is shown here. Philadelphia Atlanta Dallas Los Angeles Cost to Capacity Build Capacity Cost to Build Plant A 94 78 95 95 400 $20,000 600 $30,000 Plant B 95 Ra 88 94 400 $25.000 600 $35,000 What decision variables do you need to add to Parta? How many new decision van at do you need to add to the objective function? (2 points) b3. Write the supply constraints associated with Plant A. (4 points) 64. Discuss in general the pros and cons of adding two small plants in both dities vs. adding only on e pension Which option is better and why? (4 points bs. If the current plan is to only build one another plant in total. How can you address the requirement in the formulation? (2 points) Edit Format Table

please do not solve it in excel.

please do not solve it in excel.