Question: please do not use excell 3. CCC is a small high-precision machining company with facilities in San Francisco, Los Angelis, and Phoenix that produces specialty

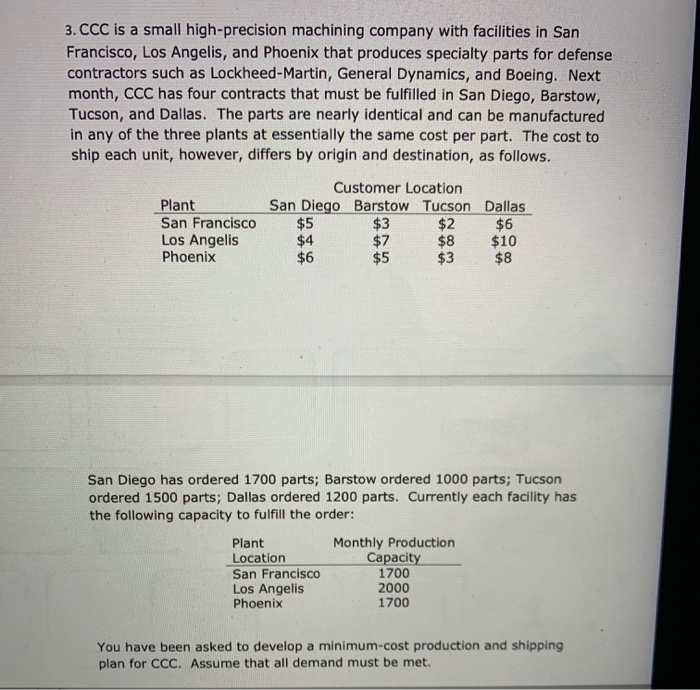

3. CCC is a small high-precision machining company with facilities in San Francisco, Los Angelis, and Phoenix that produces specialty parts for defense contractors such as Lockheed Martin, General Dynamics, and Boeing. Next month, CCC has four contracts that must be fulfilled in San Diego, Barstow, Tucson, and Dallas. The parts are nearly identical and can be manufactured in any of the three plants at essentially the same cost per part. The cost to ship each unit, however, differs by origin and destination, as follows. Customer Location Plant San Diego Barstow Tucson Dallas San Francisco $5 $3 $6 Los Angelis $4 $7 $8 $10 Phoenix $5 $8 $2 $6 $3 San Diego has ordered 1700 parts; Barstow ordered 1000 parts; Tucson ordered 1500 parts; Dallas ordered 1200 parts. Currently each facility has the following capacity to fulfill the order: Plant Monthly Production Location Capacity San Francisco 1700 Los Angelis 2000 Phoenix 1700 You have been asked to develop a minimum-cost production and shipping plan for CCC. Assume that all demand must be met

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts