Question: Please do Problem 5 and 6 (based on Problem 12.13) Problem 5. Joe Henry (see question 12.13) notices that the demand for the unit he

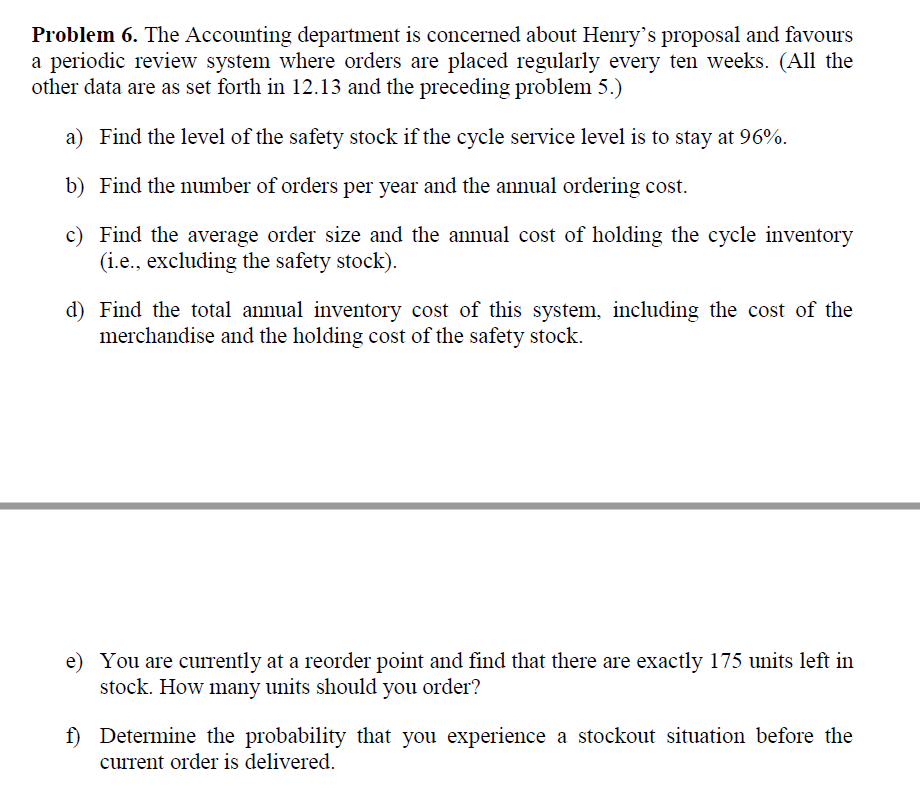

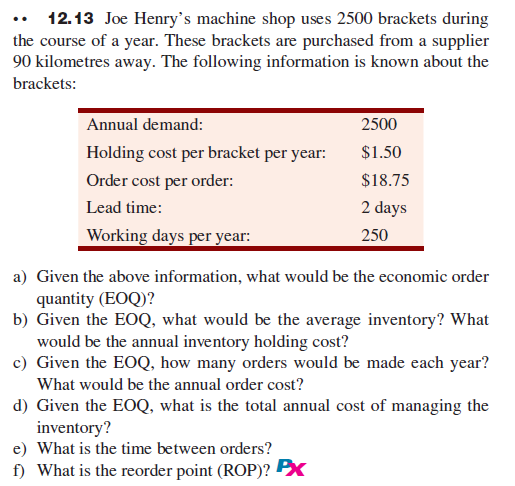

Please do Problem 5 and 6 (based on Problem 12.13)

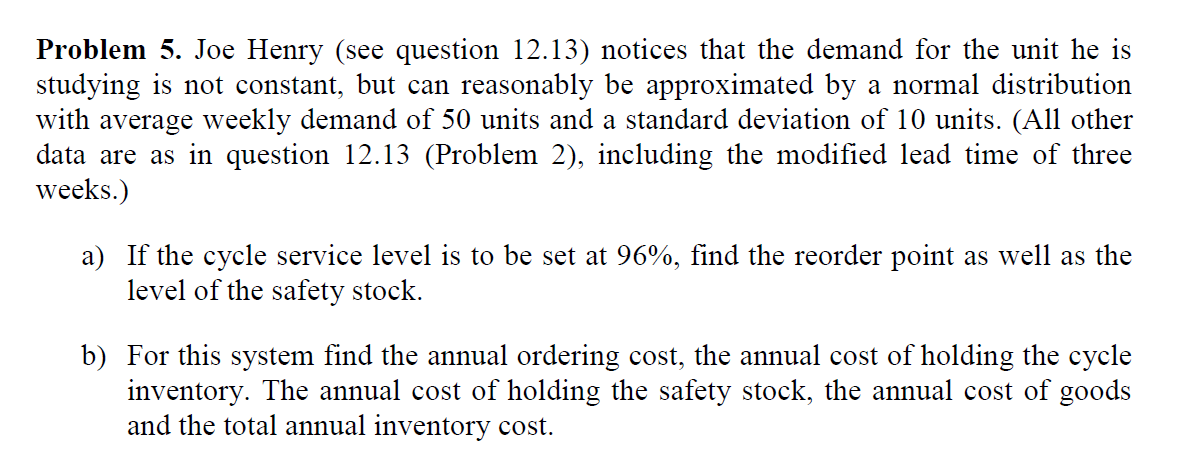

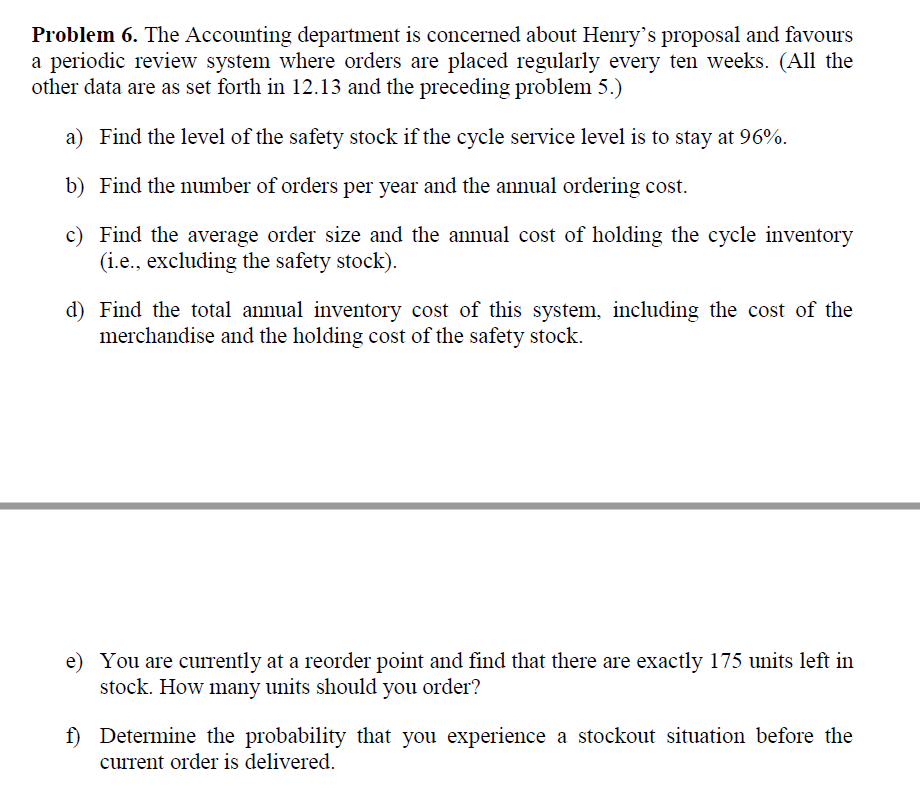

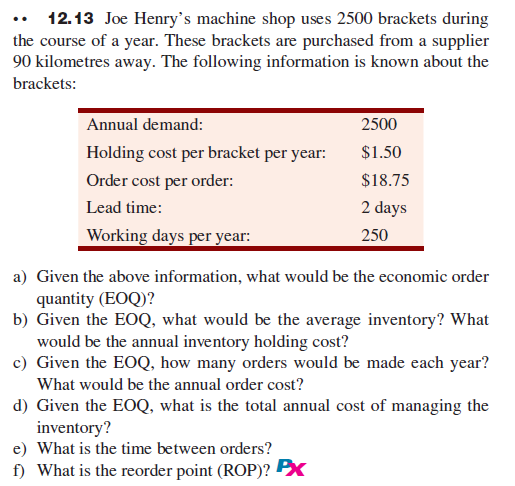

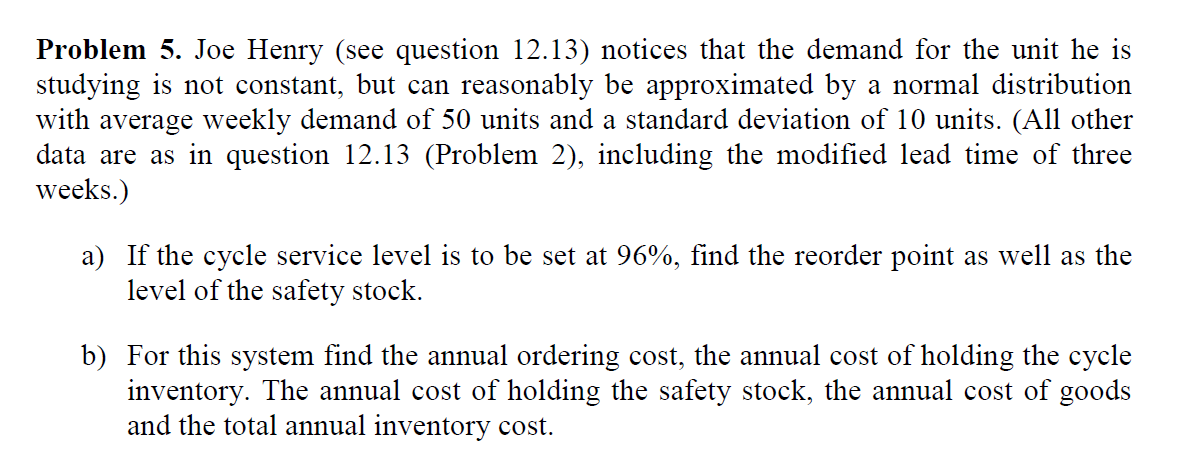

Problem 5. Joe Henry (see question 12.13) notices that the demand for the unit he is studying is not constant, but can reasonably be approximated by a normal distribution with average weekly demand of 50 units and a standard deviation of 10 units. (All other data are as in question 12.13 (Problem 2), including the modified lead time of three weeks.) a) If the cycle service level is to be set at 96%, find the reorder point as well as the level of the safety stock. b) For this system find the annual ordering cost, the annual cost of holding the cycle inventory. The annual cost of holding the safety stock, the annual cost of goods and the total annual inventory cost. Problem 6. The Accounting department is concerned about Henry's proposal and favours a periodic review system where orders are placed regularly every ten weeks. (All the other data are as set forth in 12.13 and the preceding problem 5.) a) Find the level of the safety stock if the cycle service level is to stay at 96%. b) Find the number of orders per year and the annual ordering cost. c) Find the average order size and the annual cost of holding the cycle inventory (i.e., excluding the safety stock). d) Find the total annual inventory cost of this system, including the cost of the merchandise and the holding cost of the safety stock. e) You are currently at a reorder point and find that there are exactly 175 units left in stock. How many units should you order? f) Determine the probability that you experience a stockout situation before the current order is delivered. .. 12.13 Joe Henry's machine shop uses 2500 brackets during the course of a year. These brackets are purchased from a supplier 90 kilometres away. The following information is known about the brackets: Annual demand: Holding cost per bracket per year: Order cost per order: Lead time: Working days per year: 2500 $1.50 $18.75 2 days 250 a) Given the above information, what would be the economic order quantity (EOQ)? b) Given the EOQ, what would be the average inventory? What would be the annual inventory holding cost? c) Given the EOQ, how many orders would be made each year? What would be the annual order cost? d) Given the EOQ, what is the total annual cost of managing the inventory? e) What is the time between orders? f) What is the reorder point (ROP)? PX Problem 5. Joe Henry (see question 12.13) notices that the demand for the unit he is studying is not constant, but can reasonably be approximated by a normal distribution with average weekly demand of 50 units and a standard deviation of 10 units. (All other data are as in question 12.13 (Problem 2), including the modified lead time of three weeks.) a) If the cycle service level is to be set at 96%, find the reorder point as well as the level of the safety stock. b) For this system find the annual ordering cost, the annual cost of holding the cycle inventory. The annual cost of holding the safety stock, the annual cost of goods and the total annual inventory cost. Problem 6. The Accounting department is concerned about Henry's proposal and favours a periodic review system where orders are placed regularly every ten weeks. (All the other data are as set forth in 12.13 and the preceding problem 5.) a) Find the level of the safety stock if the cycle service level is to stay at 96%. b) Find the number of orders per year and the annual ordering cost. c) Find the average order size and the annual cost of holding the cycle inventory (i.e., excluding the safety stock). d) Find the total annual inventory cost of this system, including the cost of the merchandise and the holding cost of the safety stock. e) You are currently at a reorder point and find that there are exactly 175 units left in stock. How many units should you order? f) Determine the probability that you experience a stockout situation before the current order is delivered. .. 12.13 Joe Henry's machine shop uses 2500 brackets during the course of a year. These brackets are purchased from a supplier 90 kilometres away. The following information is known about the brackets: Annual demand: Holding cost per bracket per year: Order cost per order: Lead time: Working days per year: 2500 $1.50 $18.75 2 days 250 a) Given the above information, what would be the economic order quantity (EOQ)? b) Given the EOQ, what would be the average inventory? What would be the annual inventory holding cost? c) Given the EOQ, how many orders would be made each year? What would be the annual order cost? d) Given the EOQ, what is the total annual cost of managing the inventory? e) What is the time between orders? f) What is the reorder point (ROP)? PX