Question: please explain each answer. A production manager needs to develop a production schedule to meet the following demand: Productions costs are as follows: (a) regular

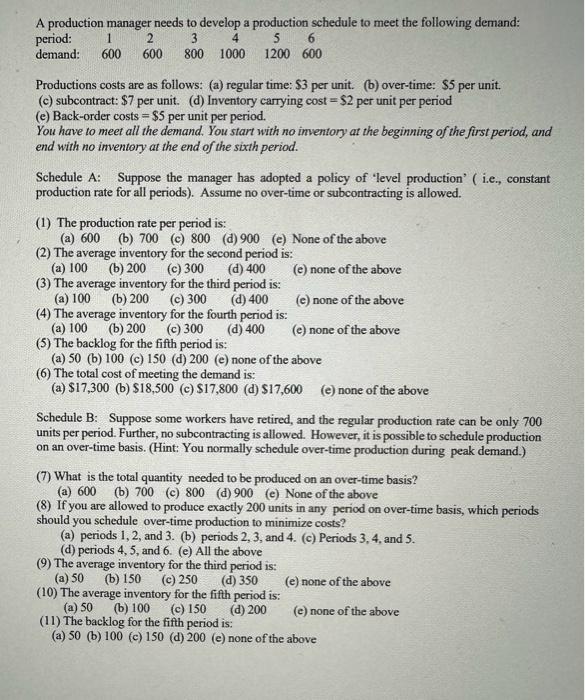

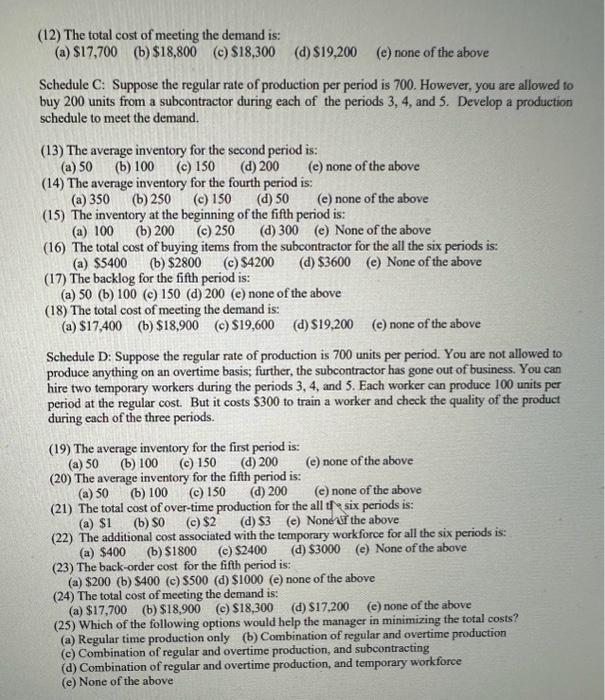

A production manager needs to develop a production schedule to meet the following demand: Productions costs are as follows: (a) regular time: $3 per unit. (b) over-time: $5 per unit. (c) subcontract: $7 per unit. (d) Inventory carrying cost =$2 per unit per period (e) Back-order costs =$5 per unit per period. You have to meet all the demand. You start with no inventory at the beginning of the first period, and end with no imventory at the end of the sixth period. Schedule A: Suppose the manager has adopted a policy of 'level production' (i.e., constant production rate for all periods). Assume no over-time or subcontracting is allowed. (1) The production rate per period is: (a) 600 (b) 700 (c) 800 (d) 900 (e) None of the above (2) The average inventory for the second period is: (a) 100 (b) 200 (c) 300 (d) 400 (e) none of the above (3) The average inventory for the third period is: (a) 100 (b) 200 (c) 300 (d) 400 (e) none of the above (4) The average inventory for the fourth period is: (a) 100 (b) 200 (c) 300 (d) 400 (e) none of the above (5) The backlog for the fifth period is: (a) 50 (b) 100 (c) 150 (d) 200 (e) none of the above (6) The total cost of meeting the demand is: (a) $17,300 (b) $18,500 (c) $17,800 (d) $17,600 (e) none of the above Schedule B: Suppose some workers have retired, and the regular production rate can be only 700 units per period. Further, no subcontracting is allowed. However, it is possible to schedule production on an over-time basis. (Hint: You normally schedule over-time production during peak demand.) (7) What is the total quantity needed to be produced on an over-time basis? (a) 600 (b)700(c)800(d)900(c)Noneoftheabove (8) If you are allowed to produce exactly 200 units in any period on over-time basis, which periods should you schedule over-time production to minimize costs? (a) periods 1, 2, and 3. (b) periods 2,3, and 4. (c) Periods 3,4, and 5 . (d) periods 4,5, and 6. (e) All the above (9) The average inventory for the third period is: (a) 50 (b) 150 (c) 250 (d) 350 (e) none of the above (10) The average inventory for the fifth period is: (a) 50 (b) 100 (c) 150 (d) 200 (c) none of the above (11) The backlog for the fifth period is: (a) 50 (b) 100 (c) 150 (d) 200 (e) none of the above (12) The total cost of meeting the demand is: (a) $17,700 (b) $18,800 (c) $18,300 (d) $19,200 (e) none of the above Schedule C: Suppose the regular rate of production per period is 700. However, you are allowed to buy 200 units from a subcontractor during each of the periods 3,4 , and 5 . Develop a production schedule to meet the demand. (13) The average inventory for the second period is: (a) 50 (b) 100 (c) 150 (d) 200 (c) none of the above (14) The average inventory for the fourth period is: (a) 350 (b) 250 (c) 150 (d) 50 (e) none of the above (15) The inventory at the beginning of the fifth period is: (a) 100 (b) 200 (c) 250 (d) 300 (e) None of the above (16) The total cost of buying items from the subcontractor for the all the six periods is: (a) $5400 (b) $2800 (c) $4200 (d) $3600 (e) None of the above (17) The backlog for the fifth period is: (a) 50 (b) 100 (c) 150 (d) 200 (e) none of the above (18) The total cost of meeting the demand is: (a) $17,400 (b) $18,900 (c) $19,600 (d) $19,200 (e) none of the above Schedule D: Suppose the regular rate of production is 700 units per period. You are not allowed to produce anything on an overtime basis; further, the subcontractor has gone out of business. You can hire two temporary workers during the periods 3,4 , and 5 . Fach worker can produce 100 units per period at the regular cost. But it costs $300 to train a worker and check the quality of the product during each of the three periods. (19) The average inventory for the first period is: (a) 50 (b) 100 (c) 150 (d) 200 (e) none of the above (20) The average inventory for the fifth period is: (a) 50 (b) 100 (c) 150 (d) 200 (e) none of the above (21) The total cost of over-time production for the all tf six periods is: (a) $1 (b) $0 (c) $2 (d) $3 (e) Noneri the above (22) The additional cost associated with the temporary workforce for all the six periods is: (a) $400 (b) $1800 (c) $2400 (d) $3000 (e) None of the above (23) The back-order cost for the fifth period is: (a) $200 (b) $400 (c) $500 (d) $1000 (e) none of the above (24) The total cost of meeting the demand is: (a) $17,700 (b) $18,900 (c) $18,300 (d) $17,200 (c) none of the above (25) Which of the following options would help the manager in minimizing the total costs? (a)Regulartimeproductiononly(b)Combinationofregularandovertimeproduction (c) Combination of regular and overtime production, and subcontracting (d) Combination of regular and overtime production, and temporary workforce (e) None of the above

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts