Question: Please find attached the case study 2: A troubled Project at Modern Materials Inc. Page 498-505 for this assignment. You will critically analyze the attached

Please find attached the case study 2: A troubled Project at Modern Materials Inc. Page 498-505 for this assignment. You will critically analyze the attached case study: A troubled Project at Modern Materials Inc. Page 498-505, summarize the key ideas, discuss the IT challenges, and present your recommendations. This report will be organized as follows: 1. Introduction Short summary of the business problem. This section will also include a background of the organization. 2. Challenges Provide for a brief description of the challenges that the organization is facing and how they are planning to address them. This section will provide the audience with a picture of how the organization is planning to address some of the challenges. 3. Change Management Discuss how change is being managed by the organization. 4. Recommendations Discuss what you would have done differently and why. 5. Conclusions Discuss the lessons learned and the key messages that you would like the audience to take away.

The report should not be more than 1000 words.

Can't upload the higher resolution pics chegg doesn't allow the file.

Please write 1000 words report Including all the above given details

And pictures would only be uploaded like this. As they do not accept high resolution pics.

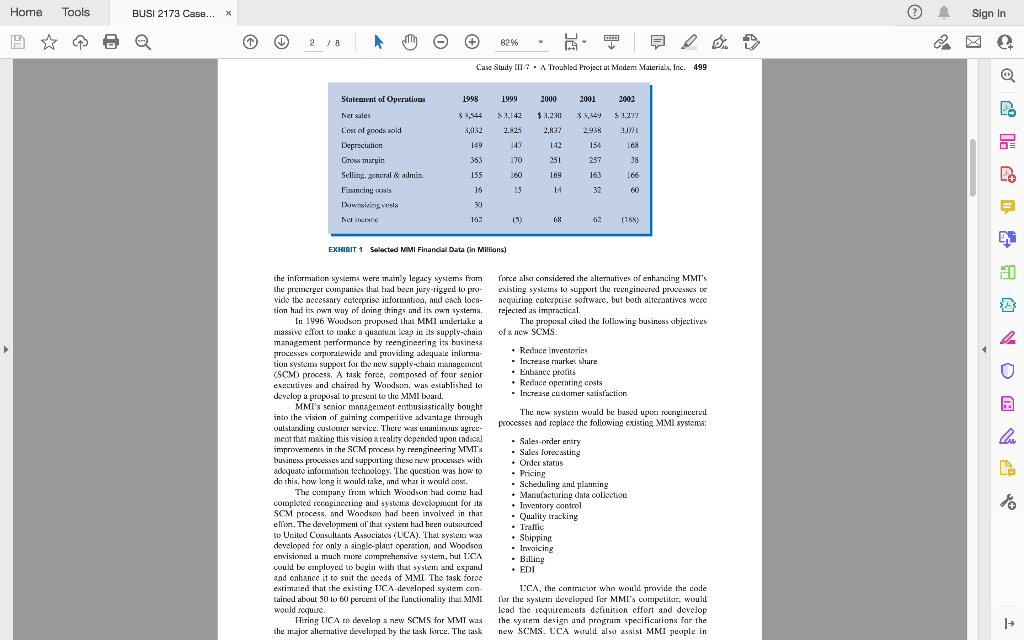

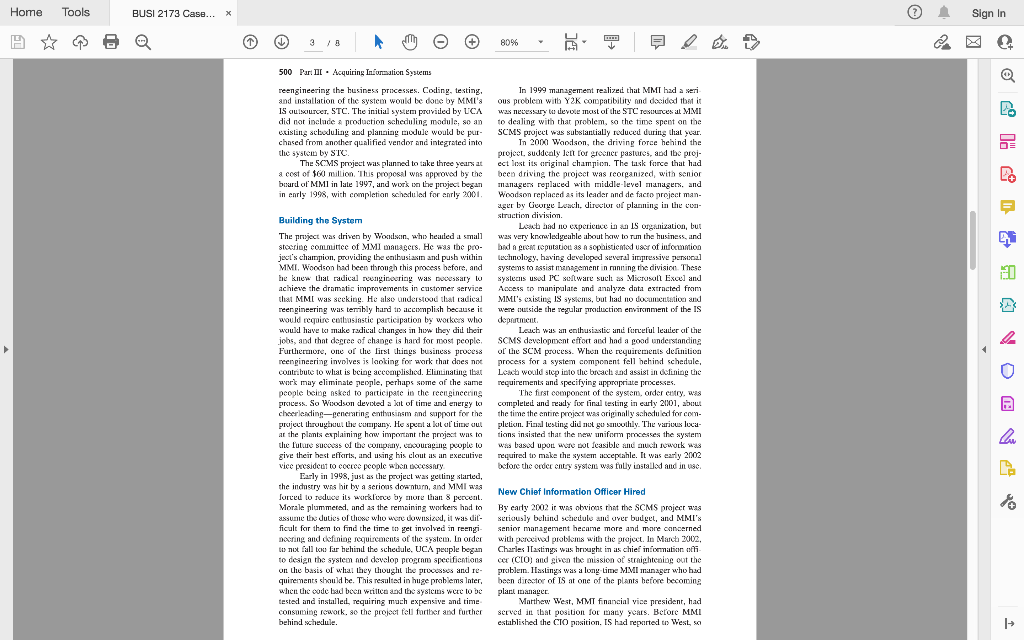

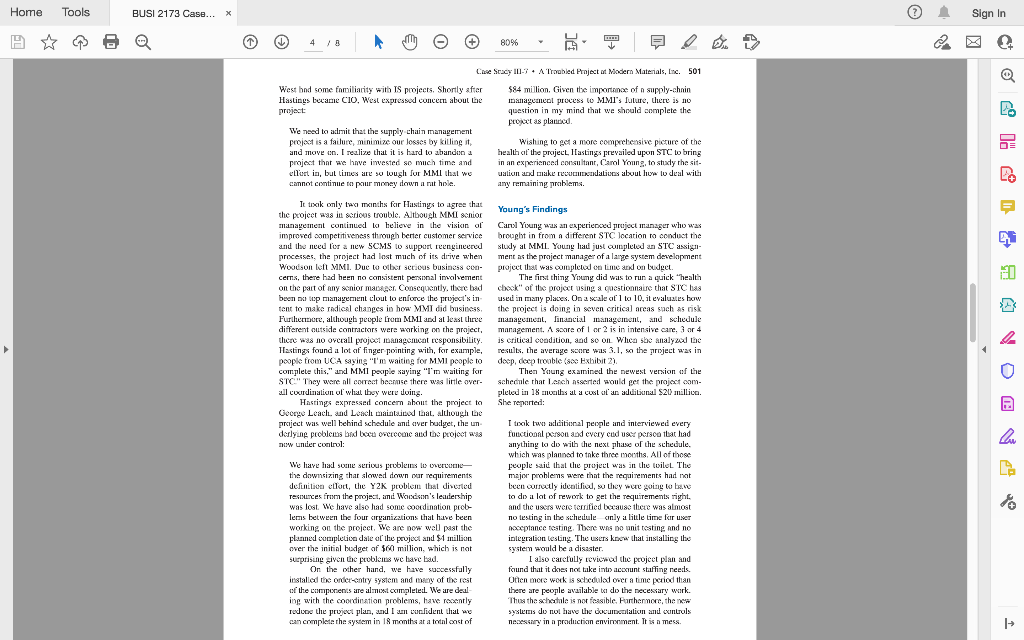

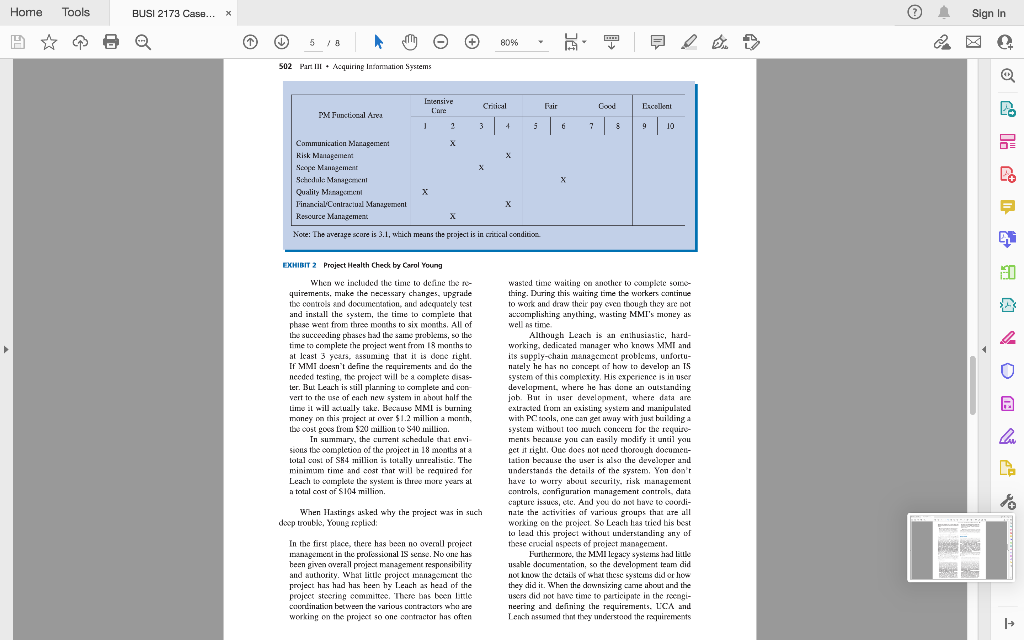

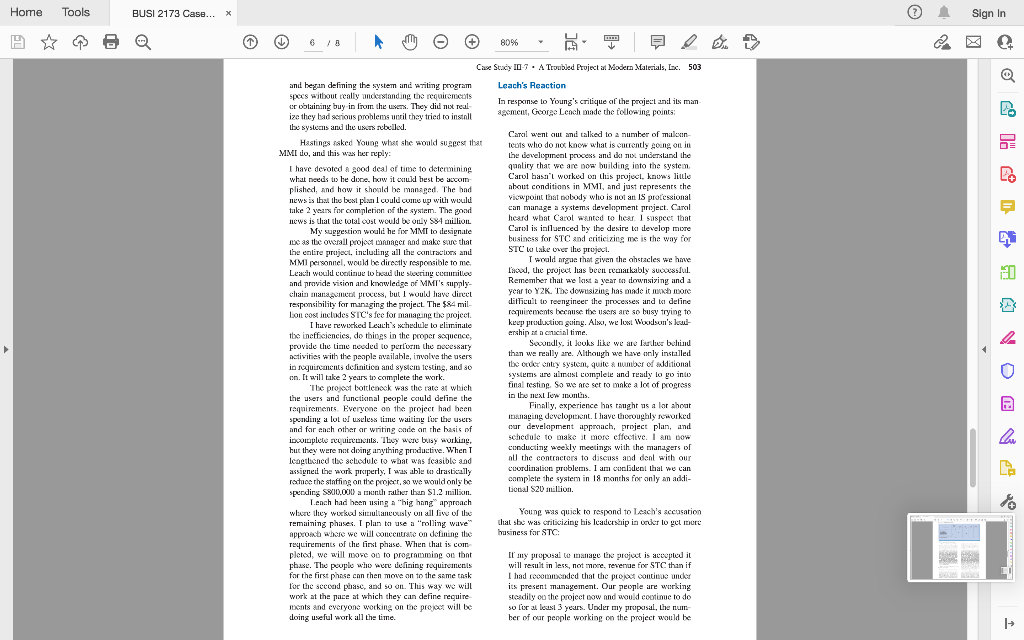

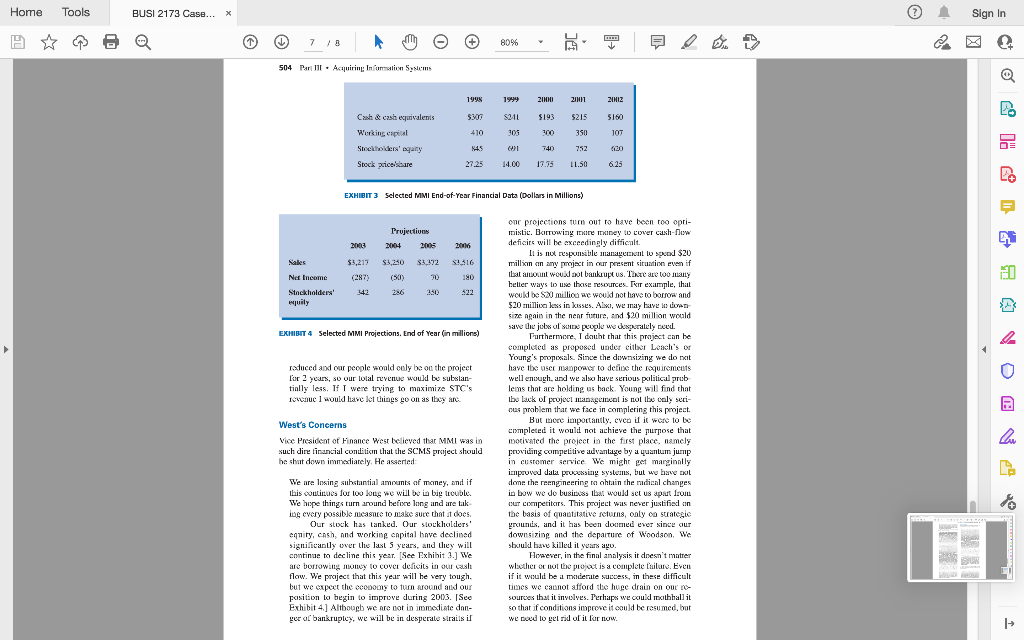

Home Tools BUSI 2173 Case... X Sign In @ 1 / 8 + 78% CASE STUDY III-7 7 A Troubled Project at Modern Materials, Inc. Le = 0 Modern Materials, Inc. (MMI) memutactures products that In 1994 MMI Outsourced its IS organization to are used as www materials by love manuaclurces and the con- STC, a major player in the IT vulsourcing business. As a struction industry. With yearly sales exceeding S3 billion, part of the contract, STC affered employment to all of mer 10.000 employees, in: four large manufacturing facili MMT'S IS people, and most of them accepted jobs with ties in the United States, MMI I one of the giants in the man SIC. Thus MMI' IS staff was very much the same as ufacturing accials inxtosty, Two of the facilities produce before, but under new macagement And the band and basic products and the other two prowuss these mazials lur- sollware were also taken over by STC. MMI retained the produce prudurls with special properties and shapes. Sinall group of analys Concord with problem delini MMI was established under another name in 1927 tion and process analysis and grew over time through a series of small mergers and acquisitions until 1991, when it took over a major comperi- Initiation of the Supply Chain Management tor and the resulting company took the name MMI. Tot System (SCMSI Project ils mamulcturing facilities came with this merger, wluca broadened MMI's product line In 1995 Harvey Woodson was hired fruen a senaller com The last several years have been difficult ones for the petitor to become executive vice president for quality at manufacturing material industry, with overcapacity, foreign MMI. Wondean brought with him a passionate vision of competition, and a depressi maafacturing economy rot- how to improve MMI's comperitive position and profitabil ting pressure ca protits. MMI his faced better than itytuowab exemplary customer service being able to take , - most of ils compellers, but as can be noted in Exhibit 1. orders, produce un product, and put it to cut with MMI bas lost money in two of the past five yours. the desired quality and package lype bea il was needed. Furthermore, at this time it looks like the year 2003 will Everyone in the industry had similar products and similar he worse than 2002. MMI went through a wrenching down quality, and Woodson helieved that outstanding customer sizing in 1998 that has left the remnining workers stretched service could make MMI srand Apart from its competirion, thin and working in hoc pc Providing outstanding customer service depends upul excel al supply chain issyorkcal, which involves Information Services at MMI entering an orier, creating a manufacturing order to guide it through the required manufacturing processes, scheduling Lp until 1994 MMI had a conventional internal IS struc- it into production, producing it, warehousing it, shipping fore, with a small corporate Is group and decentralized and routing it so that it arrives at the proper time, icicing Organizations serving the two major divisious created with and Lg us, and landling an esting issins or clairls ilal the mayor in 1991. Each pemerger company became a might aris. This chain of events starts with the initial orckor division in MMI, and each division inherited the 15 organi and carries all the way through the customer receiving and zation at the company from which it was formed Each using the product in his manufacturing process. division had its legacy people and legacy systems modified Woodson understood that excellent supply-chain to pride the necessary enterprised to corpornte IS. management depends apon efficient processes supported by appropriate information processing systems. MMI's productive processes were highly automated, will coup Coprile 2014 F. W. Martir. Abubline is local ut a patile sinsiane-UNI illa baat learly Lional computer controls, but the business processes and the digion, and find that might by the parente supporting information systems were clearly inadequate to distills provide cutstanding customer service. As previcasly noted. C 498 | Home Tools BUSI 2173 Case... X Sign In 28 2 B + 82% Case Study III 7. Trovabled Project at Modem Materials, Inc. 499 Statement of Operativas 1998 1999 2000 2001 2002 $3,142 $3.290 $3,449 $ 2.2 3,02 2.825 2,832 2958 3.071 149 142 168 143 170 154 257 353 18 Ner sales Cost of goods sold Depreciation Cross margin Selling general & admin Financing assis Downsizing costs Nerince 251 169 155 160 163 166 CA 16 15 14 32 30 162 ) (5) 68 62 (188) EXHIBIT 1 Selected MIMI Financial Data (in Millions) fisce also considered the alternatives of enhancing MMT'S existing systems to support the reengineered processos e acquiring cutcrprise software, but both alternatives were rejected as impractical The proposal cited the following business cibjectives of a new SCMS - Reduce inventories - Increase market share . Embance proti Reduce operating costs - Increase customer satisfaction 0 C The new sysle would be based upoc rengineered processes and replace the following cxisting MMI systems: the information systems were mainly legacy systems from the premerger companies thal had been jury-tigged to pro- vide the necessary cutcuprise information, and each loca- tion had its yarn way of doing things and its in systems In 1996 Woods proposed that MMI underlike a massive cifort to make a quantum lapin its supply chain management performance by reengineering its business processes corporatewide and providing adequate inca tion systems support for the new supply chain imagecent (SCM) process. A task force, composed of four senior executives and chaired by Waxlsun, was established to Jevelop a proposal to present to the MMI board. MMI's senior management entusiastically bought into the vision of gaining competitive advantage through vulstarling customer service. There was unanimou agree meet that making this vision a ceality depended upon indical improvements in the SCM pecexs by reengineering MMT'S business processes and supporting these new processes with adequate information technology. The question was how to do this, how long it would take, and whar it wald cost The company from which Woudson had come ad completed recogineering and systems developucat for its SCM process, and Woodson had been involved in that eftixt. The development of that systern hard heen outsourced to Un Consultants Associals (LCA). Tlal system was developed for only a single-plant operation, and Woodson envisioned a much more comprehensive system, but LICA would be employed to begin with the system and expand and cnhance it to suit the Deeds of MMI. The task force estimated that the existing UCA-developed system on lained alxiul 50 W 60 percent of the functionality that MMI would require Hiring UCA to develop a new SCMS for MMT was the major alternative developed by the task force. The task Sales-order entry Sales forecasting Order status Pricing Scheduling and planning Manufacturing data collection Inventory control . Quality tracking Trafic Shipping - Inscricing Billig EDI LICA, the contractor who would provide the code l'or the system developed for MMI's competik, would Icad the icquchouts dotuition cffort and develop the system design and program specifications for the new SCMS. UCA would also assist MMI people in | Home Tools BUSI 2173 Case... X Sign In @ 3 3 80% 2 500 Par: III. Acquiring Information Systems reengineering the business processes. Coding, testing, and installation of the system would be done by MMI's IS CIUILTET, STC. The initial system provided by LCA did not include a production scheduling module, so an , veisling scheduling and planning module would be pur- chased from another qualified vendor and integrated into the system by STO The SCMS project was planned to take three years at a cost of 100 million. This proposal was approved by the beard of MMI in late 1997, and work in the project began in enrly 1998, with completion scheduled for enrly 2001 Building the System The preject was driven by Wool, who headed a small steering committee of MMI managers. He was the pro- ject's champion, providing the enthusiasm and push within MMI, Woodson had been through this process before, and he knew that radical wengineering was sucessary to achieve the dramatic improvements in customer service the MMI was seeking. He also understood that radical reengineering was terribly hard to accomplish because it would require cettosiastic participation by workers who would have to make radical changes in how they did their jobs, and that degree of change is hard for most people Furthermore, one of the lirst things business process reengineering involves is looking for work that does not contribute to what is being accomplished. Eliminating that . work may eliminate people, perhaps some of the same people being asked to participate in the reengineering process. So Woodson devoted a kit of time and energy to cheerleading-enerating enthasinum and support for the project throughout the cuspany. He spolu all out at the plants explaining how important the project was to the future success of the comply. Coulugang pople lo give their best efforts, and using his clout is an executive viec pecsidcut to coccee people who doessary Early in 1998, just as the project was getting klarted, the incastry was hit by a serious downturn, and MMI 38 Torced to reduce its workloce by more than 3 percent. Morale plummered, and as the remaining workers had to assume the duties of those who were downsizod, it was dit- ficult for them to find the time to get involved in reengi Daring and defining requirements of the system. In order to not fall too far behind the schedule. UCA peuple began to design the systeon and develop program specifications on the basis of what they thought be processes and re- quirements should be. This resulted in huge problems Inter, when the code bad been written and the systems were to be tested and installed, requiring much expensive and time consuming work, so the projet fell farther and further behind schedule. In 1999 management realized that MMT had a seri ous problem with Y2K compatibility and decided that it was necessary to devote most of the STC TOUTES at MMI to dealing with that problem, so the time spent on the SCMS project was substantially reduced during that year. In 2000 Woodson, the driving force hehind the project, suddcaly lett for grochet pastures, and the proj- ect lost its original champion. The task force that had been driving the project was reorganized, with senior managers replaced with middle-level managers, and Woodson replaced as its leader and de facto project man- ager by George Leuch, director of plarining in the con- struction division Leat ad no experience in a lS organization, but was very knowledgeable about how to run the husiness, and had a great reputation as a sophistionod usor of information technology, having develuped several impressive personal systems to assist moment in running the division. These xyxlens used IPC soll ware such as Micro Excel and Access to manipulate and analyze data extracted from MMI's cxisting 18 systems, but had no documentation and were outside the regular production environment of the IS department Leuch was an enthusiastic and forceful leader of the SCMS development effort and had a good understanding of the SCM process. When the requirements definition process for a system component fell hehind schedule, Leat would step into the breach and assist in defining the requirements and specifying appropriate processes. The first component of the system, order entry, was completed and ready foxetinal testing in early 21/01, about the time the entire project was originally scheduled for com- pletion. Final testing did not go smoothly. The various loca- tions insisted that the new uniform processes the system was based upon wure not feasible and much mork was required to make the system acceptable. It was early 2002 before the order entry systems was fully installed and in use. 9 SPgo As New Chief Information Officer Hired By early 2002 ir was obvices that the SCMS project was seriously behind schedule and over budget, and MMI'S senior management became more and more concerned with porocio problems with the project. In March 2002, Charles Castings was hrought in as chief information CEE (CIO) and given the mission of strnightcoing out the problem. Hastings was a long time MMI manager who had been director of IS at one of the plants before becoming plant manager Matthew West, MMT financial vice president, had served in that position for many years. Before MMI established the CTO position. I had reported to West, so | Home Tools BUSI 2173 Case... X Sign In @ 4 3 80% 2 Cue Stacy 10-7. Trovabled Project Modern Materials, Inc. 501 West bnd some familiarity with IS projects. Shortly after $84 million. Given the importance of supply-chnin Hastings became CIO, West expressed concern about the Imagenel process to MMI's future, there is no project question in my mind that we should complete the project as plaud We need to admit that the supply chain management project is a failure, minimize our losses by killing it Wishing to get a more comprehensive picture of the and move on. I realize that it is hard to abandona health of the project. Hastings prevailed upon STC to bring project thnt we have invested so much time and in an experienced consultanr, Carol Young, to study the sit- ellert in, but times are so lough for MMI that we alion and make recordations about how to deal with cannot continue to pour money down a nut hole. any remaining problems It txak only two mainch for lastings to agree that the project was lusorious trouble. Altbough MMI schior Young's Findings management continued to believe in the vision of Carul Young was an experienced project manager who was improved competitiveness through berter customer service brought in from a different STC location to conduct the and the need for a new SCMS to support reengineered study at MML. Young and just completed an STC assiga processes, the project had lost much of its drive when ment as the project manager of a large system development Woodson leh MMI. Due to the serious business con- project that was completolon Lime and on budget. cems, there had heen no consistent personal implement The first thing Young did was to run a quick "health on the part of any senior manager. Consequently, the band check of the project using a questionnaire that STC has " been notip management clout to enforce the project's in used in many places. On a scale of 1 to 10, it evaluates how tent to make radical changes in how MMI did business the project is doing in seven critical aceas such as risk Furthermore, although people crom MMI and at least three management, financial management, and schedule different outside contractors were working on the project, management. A score of 1 or 2 is in intensive care, 3 or 4 there was no overall project managoncal responsibility, is critical condition, and SO OIL Wlica sbc analyze the Hastings found a lot of finger pointing with, for example, results, the average score was 3.1, so the project was in people from UCA saying "I'm waiting for MMI people to deep, deep trouble (no Exbibit) complete this," and MMI people saying "I'm waiting for Then Young examined the newest version of the STC" They were all correct become there was linle over- schedule that loch Assorted would per the project com. all coordination of what they were doing. pleted in 18 months at a cost of an additional $20 milliva. Hastings expressed concern about the project to She reported: George Leacli and Lonchaninta taal, although the project was well behind schedule ani aver budget, the un in cucu ante I took two additional people and interviewed every derlying problems bad boca recome and the project 133 functional person and every cud user perscatarlad now under control anything to do with the next phase of the schedule. which was planned to take three months. All of these We have had some serious problems to overcome people said that the project was in the toilet The the downsizing that slowed down ar requirements major peoblems were that the requirements had not definition etlott, the Y2K problem that diserted been correctly identifical, so they were going to be Tesources from the project, and Woodson's leadership to do a lot of rework to get the requirements right was lost. We have also had some coordination preb and the users were terrified because there was almost lems between the four ciryanications that have been no testing in the schedule only a little time for user working on the project. We are now well past the neceptance testing. There was no unit testing and no planned completion date at the project and $1 million integration testing. The users know that installing the over the initial budget of $0 million, which is not system would be a disaster surprising given the problems we have bad. I also carefully Levicwal the project plan and On the other hand, we have successfully found that it does not take into acerunt staffing needs. installed the order-catry system and many of the rest Often mere work is scheduled over a time period than of the components are almost impleted. We are deal there are people available to do the necessary work. ing with the coordination problems, have recently Thus the school is not feasible. Furthermore, the new reduce the project plan, and I am confident that we systems do not have the counculation and controls can complete the system in 18 months at a total cost of necessary in production environment. It is a mess. 9 SPgo As | Home Tools BUSI 2173 Case... X X Sign In @ 5 B 80% le E 19 2 502 Part Ill. Acquiring Internation Systems Intensive Care Critical Good Excellent PM Tunctional Anu ] 1 3 + 5 7 8 9 10 | X X Communication Management Risk Management Soge Management Schedule Map Quality Man Financial Contractual Management Resource Management X X = X Note: The average score is 3.1, which means the project is in critical condition EXHIBIT 2 Project Health Check by Carol Young When we included the time to define the re- quirements, make the necessary changes, upgrade the controls and documention, and adequately lost and install the system, the time to complete that phase went from three months to six months. All of the succeediny pases bad ibe same problems, so the time to complete the project went from 18 months to at least 3 years, assuming that it is done riglui. If MMI doesn't define the requirements and do the needed testing, the project will be a complere disas- ter. But Leuch is still planning to complete and con vert to the use of each new system in about half the Lite il will actually lake. Because MMI is burning money in this project at wwer $1.2 million a month. be cost goes from $20 million to 940 million. In summary, the current schedule that envi Sious the completion of the project in 18 moottes at a Lolaloms of SH4 million is kitally unrealistic. The minimum rime and cost that will be required for Leach locuplete the system is the ke years al a total cost of S104 million wasted time waiting on another to complote sol thing. During this waiting time the workers continue to work and draw their pay excetbough they are not accomplishing anything, wasting MMI's money as well as time Although Leach is an onibusiastie, hard- working, dedicated manager who knows MMI and its supply-chain management problems, unfortu- nately he has no concept af how to develop an IS system of this complexity. His experience is in user develapment, where he has done an outstanding jab. Kur in user development, where data are extracted treen 2.1 existing system and manipulated with Pools, on an get away with just building a system witbout too much concern for the require ments because you can easily modify it until you get it right. Ouc does not need thorough documeu- Lation because the user is also the developer and understands the details of the system. You don't have to worry about security, risk management controls, configuration management controls, data capture issues, et, And you do not have to coordi- nate the activities of various groups that are all working on the project. So Leach has tried his best to lead this project without understanding any of tbese crucial spects of project management Furthermore, the MMI legacy systems and little usable documentation, so the development team did Hoe know the details of what these systems did on they did it. When the downsizing care about and the users did not have time to participate in the recogi- neering and defining the requirements. LCA and Lenchenssumed that they understood the requirements @ g SP xo Ae When lastings asked why the project was in such deep trouble, Young, replied In the first place, there has been no overall project Inagement in the professional IS sro. No one has teen given averall project management responsibility and authority. What little project management the project has had has heen hy Leuch as head of the project steering committee. There has been little Corinalin between the various contractors who are working on the project so one contractor has often Home Tools BUSI 2173 Case... X X Sign In @ 80% le 2 Cc = Case Study 10-7. A Troubled Project at Modern Matecials, Lc. 503 and began defining the system und writing program Leach's Reaction specs without really understanding the requirercats croblaining buy in from the uvex. They did not real- In response to Young's critique of the project and is man ize they had scrious problems woril they tried to install agement, George Leach made the following points the systems and the uses rebelled. Caral went out and talked to a number of malen Hastings isked Young what she would suggest that tcuts who do not know what is currently going on in MMI do, and this was her reply: the developinent process and my understand the I have devoted a good deal of time to determining quoliry that we are now building into the system what needs to be done, hxw it u best be accom Carol basa'l worked on this project, knows little plished, and how it shoald be managed. The had about conditions in MMI, and just represents the news is that the best plan I could come up with would Vicwpoint that nobody who is not an IS professional take 2 years for completion of the system. The good can manage a systems development project. Carol news is that total cost would be only $81 million heard what Carol wanted to hear I suspect that My suggestion would he fixe MMI to designate Carol is influenced by the desire to develop more Le as the overall project manager and make sure that business for STC and criticizing me is the way for the entire project, including all the contractors and STC to take over le project. MMI personnel, would be directly responsible to me I would argue that given the obstacles we have Leach would continue to bude slooring ceni. l'aod, die project has been reutatkably successful. and provide vision and knowledge of MMT's supply Remember that we last a year to downsizing and a chain manage process, but I would have direct year to Y2K. The downsizing has made it much more responsibility for managing the project. The $84 mil- difficult to reengineer the processes and to define Lon cost includes STC's fee for managing the project requirements because the users are so busy trying to I have nowoked Leach's schedule to eliminate keep production going. Alm, we lov Woodson's lui tbc incfficiencies, do things in the proper sequence, ership this time provide the Lime needed to perform the necessary Secondly, it looks like we are far behind activities with the people available, involve the users than we really are. Although we have only installed in quirements definition and system testing, and so tbc Oudker only system, quite a number of ditional on. It will take 2 years to complete the work. systems are all complete and ready to go into The project bottleneck was the rate at which final testing. So we are set to make a lot of progress a the users and functional people could define the in the next low man. requirements. Everyone on the project had been Finally, experience has taught as a lor about spending a lot of useless time waiting for the users imaging development. I have thoroughly worked and for ench other ar writing onde on the basis of cur development approach, project plan, and incomplete requirements. They were busy working, schedule to make it more cffective. I am now but they were not doing anything productive. When I conducting weekly meetings with the managers of Icagttcncd tc scliodule to what was feasible and all the contractors to discuss and dent with our assigned the work properly, I was able to drastically coordination problemas. I am confident thal we can restuce the staffing on the project, so we would only be complete the system in 18 months for only an addi- spending S800.001) a bunch Taller than $1.2 million. Local S20 million Lench had been using a "highing approach wloze liey wukol sultaneously on all live of the Young was quick to respond to Leach's accusation remaining phases. I plan to use a "rolling wave that she was criticizing his cadastrip in under to get more Approab where we will concentrate on dcfining the Thrusiness for STC: requirements of the first phase. When that is com pleted, we will more on to programming on that If my proposal to manage the project is accepted it pbase. The people who were defining requirements will result in less, not mone, revenue for STC than if for the first phase can then move on to the same task I had recommended that the pro Continuo under for the second phase, and so on. This way we will its present management. Our people are working work at the pace at which they can define require steadily on the project bow and would cootinue to do ments and everyone working on the projet will be so ler at last 3 years. Under my propisal, the num doing useful work all the time ber of our people working on the project would be 0 C | Home Tools BUSI 2173 Case... X X Sign In @ 7/B + 80% la 2 504 Par 111. Acquiring Information Systems 1998 1999 201000 211 2012 Cash & cash equivalents SY S211 $193 5215 $150 410 205 400 350 JOT Working capital Stockholders' qarty Stock prices are 031 740 752 (130 27.25 14.00 . 17 11.50 6.25 EXHIBIT 3 Selected MMI End-of-Year Financial Data (Dollars in Millions) 2003 2016 Prujectius 2004 2005 $3,250 $5,372 (50) Sales $3,217 SI56 (287) 180 Net Income Stockholders' wuity 142 350 322 9 SPxo 44 EXHIBIT 4 Selected MMI Projections. End of Year (in millions) reduced and our people would only be on the project for 2 years, so our lolal revenue would be substan- tially less. If I were trying to maximize STC's Itenuc I would have let things go on as they are ont projections turn out to have been too opti- mistic. Borrowing ituire lexiney to cover cash-flow deficits will be exceedingly difficult Il is not responsible manage to spend $20 million in any project in our present situation even if that amount would not banka upus. The are too many helter ways to use those resources. Txir example, that would be S20 million we would not have to borrow and $20 millia lexs in kisses. Also, we may have leden size ngain in the near future, and $20 million would Save the juks oleme prople we desperately need. Turthermore, I doubt that this project can be completed as proposed under citar Lonchi's or Young's proposals. Since the downsizing we do not have the user man power to define the requiremcuts well enough, and we also have serious political prob lems that are holding as back. Young will find that the lack of project manager.col is not be caly seci- les problem that we face in completing this project. But more importantly, evca if it were to be completed it would not achieve the purpose that motivated the project in the first place, namely providing competitive advanlage by a quantum jump in customer service We might get marginnily improved data processing systems, but we have dil done the reengineering to chtain the radical changes in bow we do busiowasibu would act us apart from cur competitors. This project was never justified an the basis of quantitative returns, only a strategic yrcuns, and it has been coamed ver since our downsizing and the departure of Woodson. We sbould have killed it years ago However, in the final analysis it doesn't matter Wether or not the project is a complete l'ailure. Even if it would be a moderate success in these difficult times we cannot afford the huge drain on our - sources that it involves. Perhaps we could nothball it so that if conditions improve it could be resumed.lbot we boud to get rid of it for now. West's Concerns Vice President of Finance West believed thar MMI was in such dire tinancial condition that the SCMS project should The shut down immediately. He asserted We are losing substantial amounts of money, and if This continues for too long we will be in big trouble We hope things turn around before long and ure tak ing every possible cauce to make sure that it does. Our stock has lanked. Our stockholders' qnity, cash, and working onpital have declined significantly over the last 5 years, and they will continue to decline this year. See Exhibit 1.) We are borrowing money to cover deficits in our cash flow. We project that this year will be very tough. but we expect the cocong to turn around and our position to begin to improve during 2003. See [ Exhibit 4.] Although we are not in immediate dan- per of bankrupley, we will be in desperate stais il | Home Tools BUSI 2173 Case... X X Sign In 100% le 2 Case Study T-7. A Troubled Project at Modern Materials. Inc. 505 Leach contested West's assertion that the new system would not provide the competitive advantage originally cnvisioned: Cc = We have only installed one subsystem, and you can- not expect overall performance to be improved much until the entire system is installed and working. The results of this effort will be apparent when the full system is completed and installed. Our legacy systems that run production at the plants are stand-alone systems that are not integrated with other production systems or with the support systems administrative, financial, personnel, etc. The new system will integrale everything from the time the customer calls in an order through ordering the raw materials, scheduling and following through the production process, entering it into inventory shipping it, billing it, and handling any problems with the use of the product. As a result, the customer will be able to get exactly what he wants in the shortest possible time. When the customer calls with an order, it can be entered, scheduled, and the delivery date determined while the customer is on the phone. Changes to an order can be made quickly and eas- ily. The load time to deliver an order will be reduced from today's 120 days to 45 days, which is just a little more than a third of what it is today! That will be a huge improvement in customer service. No one else in our industry will be able to Furthermore, with this integrated system, man- agement information will be available in real time rather than months after the fact. We will be able to determine the profitability of cach product and focus our marketing cfforts on the most profitable prod- ucts, and we will be able to plan our production and load it on our facilities so as to minimize the cost of production. Not only will we be able to radically improve customer service, but we will also be able to improve the profitability of what we produce I admit that the project has had its problems, but I am sure that we can complete it in 18 months for an additional $20 million. Although our financial condition is not good, this is a strategic project that will greatly improve our competitiveness. It repre- sents a crucial top management vision, and I can't believe that we would abandon it because of tempo rary dilliculties. MMI's future depends upon it! 0 Mary J. Ellis, the construction division's represen- tative on the project steering committee, believed that the project should be continued and that Leach should continue to lead it. She asserted: C Admittedly our financial condition is not the best, but $20 million is not going to make or breuk us. We must not let short-range problems cause us to lose the vision that can make such an important contribu- tion to MMI's long-term success. George has the vision, the enthusiasm, and the experience needed to complcte the project. George has provided outstanding leadership, tighting through difficulty after difficulty. Without George's drive and enthusiasm the project would have failed long ago. It would be disastrous to change leadership now when the project is so close to completion. match this. Also, this reduction in the time to deliver an order will result in tremendous savings for MMI because in- process inventory will be reduced so dramatically. And time is money for us as well as for our customers. We . will be saving huge amounts of money, |

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts