Question: Please Formulate as a Linear Programming model with detailed steps Thank you so much for helping out in Advance (6.) (a) Baker Robbins & Company

Please Formulate as a Linear Programming model with detailed steps

Thank you so much for helping out in Advance

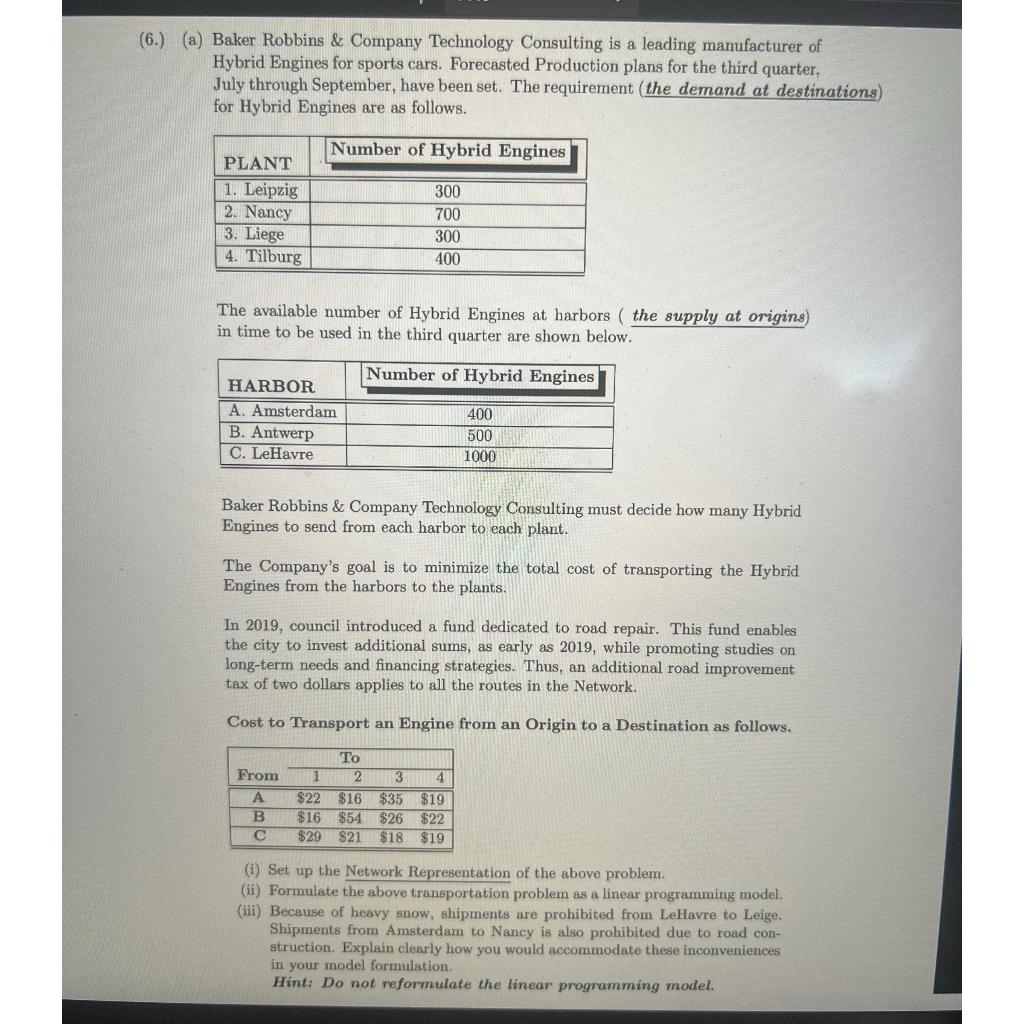

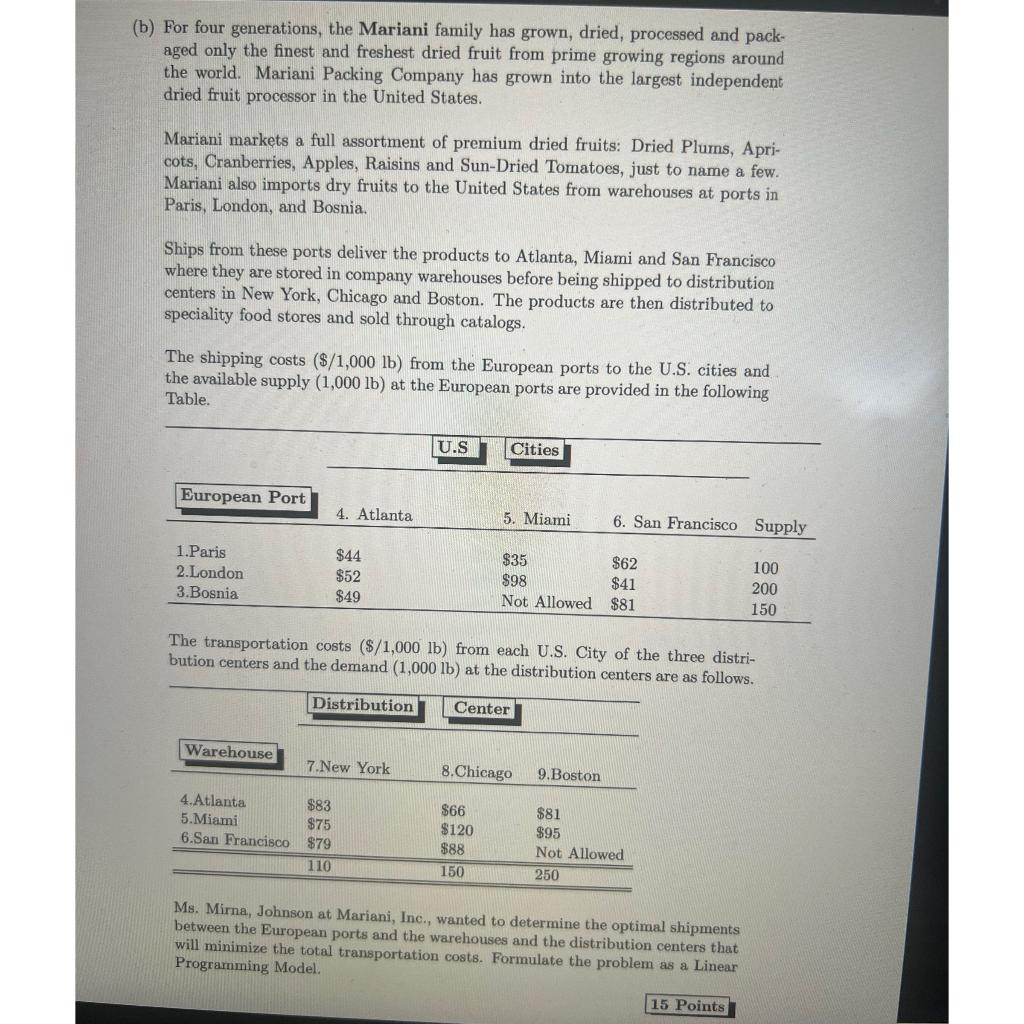

(6.) (a) Baker Robbins & Company Technology Consulting is a leading manufacturer of Hybrid Engines for sports cars. Forecasted Production plans for the third quarter, July through September, have been set. The requirement (the demand at destinations) for Hybrid Engines are as follows. Number of Hybrid Engines PLANT 1. Leipzig 300 2. Nancy 700 3. Liege 300 4. Tilburg 400 The available number of Hybrid Engines at harbors (the supply at origins) in time to be used in the third quarter are shown below. Number of Hybrid Engines HARBOR A. Amsterdam 400 B. Antwerp 500 C. LeHavre 1000 Baker Robbins & Company Technology Consulting must decide how many Hybrid Engines to send from each harbor to each plant. The Company's goal is to minimize the total cost of transporting the Hybrid Engines from the harbors to the plants. In 2019, council introduced a fund dedicated to road repair. This fund enables the city to invest additional sums, as early as 2019, while promoting studies on long-term needs and financing strategies. Thus, an additional road improvement tax of two dollars applies to all the routes in the Network. Cost to Transport an Engine from an Origin to a Destination as follows. From To 1 2 3 4 $22 $16 $35 $19 A B $16 $54 $26 $22 C $29 $21 $18 $19 (i) Set up the Network Representation of the above problem. (ii) Formulate the above transportation problem as a linear programming model. (iii) Because of heavy snow, shipments are prohibited from LeHavre to Leige. Shipments from Amsterdam to Nancy is also prohibited due to road con- struction. Explain clearly how you would accommodate these inconveniences in your model formulation. Hint: Do not reformulate the linear programming model. (b) For four generations, the Mariani family has grown, dried, processed and pack- aged only the finest and freshest dried fruit from prime growing regions around the world. Mariani Packing Company has grown into the largest independent dried fruit processor in the United States. Mariani markets a full assortment of premium dried fruits: Dried Plums, Apri- cots, Cranberries, Apples, Raisins and Sun-Dried Tomatoes, just to name a few. Mariani also imports dry fruits to the United States from warehouses at ports in Paris, London, and Bosnia. Ships from these ports deliver the products to Atlanta, Miami and San Francisco where they are stored in company warehouses before being shipped to distribution centers in New York, Chicago and Boston. The products are then distributed to speciality food stores and sold through catalogs. The shipping costs ($/1,000 lb) from the European ports to the U.S. cities and the available supply (1,000 lb) at the European ports are provided in the following Table. U.S Cities European Port 4. Atlanta 5. Miami 6. San Francisco Supply 1.Paris $44 $35 $62 100 2.London $52 $98 $41 200 3.Bosnia $49 Not Allowed $81 150 The transportation costs ($/1,000 lb) from each U.S. City of the three distri- bution centers and the demand (1,000 lb) at the distribution centers are as follows. Distribution Center Warehouse 7.New York 8. Chicago 9.Boston 4.Atlanta $83 $66 $81 5.Miami $75 $120 $95 6.San Francisco $79 $88 Not Allowed 110 150 250 Ms. Mirna, Johnson at Mariani, Inc., wanted to determine the optimal shipments between the European ports and the warehouses and the distribution centers that will minimize the total transportation costs. Formulate the problem as a Linear Programming Model. 15 PointsStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts