Question: please give answer Case Description This assignment will test your skills to conduct an analysis of an MRP. Consider your role as that of a

please give answer

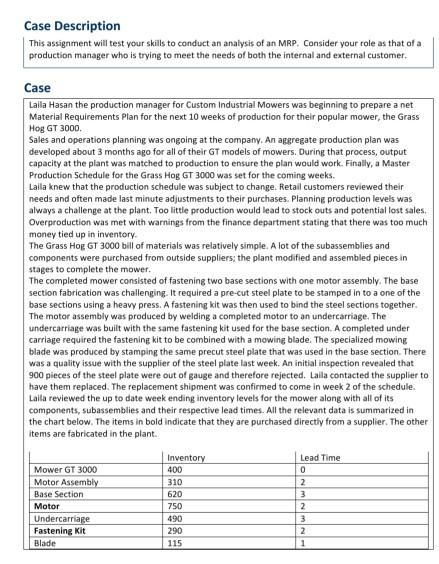

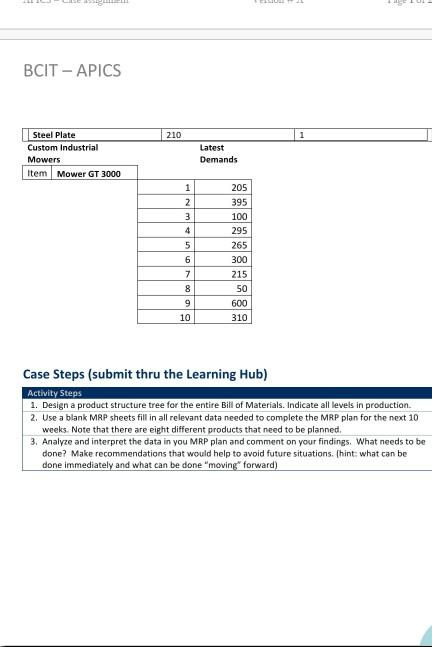

Case Description This assignment will test your skills to conduct an analysis of an MRP. Consider your role as that of a production manager who is trying to meet the needs of both the internal and external customer. Case Laila Hasan the production manager for Custom Industrial Mowers was beginning to prepare a net Material Requirements Plan for the next 10 weeks of production for their popular mower, the Grass Hog GT 3000 Sales and operations planning was ongoing at the company. An aggregate production plan was developed about 3 months ago for all of their GT models of mowers. During that process, output capacity at the plant was matched to production to ensure the plan would work. Finally, a Master Production Schedule for the Grass Hog GT 3000 was set for the coming weeks. Laila knew that the production schedule was subject to change. Retail customers reviewed their needs and often made last minute adjustments to their purchases, Planning production levels was always a challenge at the plant. Too little production would lead to stock outs and potential lost sales, Overproduction was met with warnings from the finance department stating that there was too much money tied up in inventory The Grass Hog GT 3000 bill of materials was relatively simple. A lot of the subassemblies and components were purchased from outside suppliers, the plant modified and assembled pleces in stages to complete the mower. The completed mower consisted of fastening two base sections with one motor assembly. The base section fabrication was challenging. It required a pre-cut steel plate to be stamped into a one of the base sections using a heavy press. A fastening kit was then used to bind the steel sections together. The motor assembly was produced by welding a completed motor to an undercarriage. The undercarriage was built with the same fastening kit used for the base section. A completed under carriage required the fastening kit to be combined with a mowing blade. The specialized mowing blade was produced by stamping the same precut steel plate that was used in the base section. There was a quality issue with the supplier of the steel plate last week. An initial inspection revealed that 900 pieces of the steel plate were out of gauge and therefore rejected. Laila contacted the supplier to have them replaced. The replacement shipment was confirmed to come in week 2 of the schedule. Laila reviewed the up to date week ending inventory levels for the mower along with all of its components, subassemblies and their respective lead times. All the relevant data is summarized in the chart below. The items in bold indicate that they are purchased directly from a supplier. The other items are fabricated in the plant. Mower GT 3000 Motor Assembly Base Section Motor Undercarriage Fastening Kit Blade Inventory 400 310 620 750 490 290 115 Lead Time 0 2 3 2 3 2 1 BCIT - APICS 210 1 Steel Plate Custom Industrial Mowers Item Mower GT 3000 Latest Demands 1 2 3 4 5 205 395 100 295 265 300 215 50 600 310 6 7 8 9 10 Case Steps (submit thru the Learning Hub) Activity Steps 1. Design a product structure tree for the entire Bill of Materials. Indicate all levels in production 2. Use a blank MRP sheets fill in all relevant data needed to complete the MRP plan for the next 10 weeks. Note that there are eight different products that need to be planned. 3. Analyze and interpret the data in you MRP plan and comment on your findings. What needs to be done? Make recommendations that would help to avoid future situations. Thint: what can be done immediately and what can be done "moving forward) Case Description This assignment will test your skills to conduct an analysis of an MRP. Consider your role as that of a production manager who is trying to meet the needs of both the internal and external customer. Case Laila Hasan the production manager for Custom Industrial Mowers was beginning to prepare a net Material Requirements Plan for the next 10 weeks of production for their popular mower, the Grass Hog GT 3000 Sales and operations planning was ongoing at the company. An aggregate production plan was developed about 3 months ago for all of their GT models of mowers. During that process, output capacity at the plant was matched to production to ensure the plan would work. Finally, a Master Production Schedule for the Grass Hog GT 3000 was set for the coming weeks. Laila knew that the production schedule was subject to change. Retail customers reviewed their needs and often made last minute adjustments to their purchases, Planning production levels was always a challenge at the plant. Too little production would lead to stock outs and potential lost sales, Overproduction was met with warnings from the finance department stating that there was too much money tied up in inventory The Grass Hog GT 3000 bill of materials was relatively simple. A lot of the subassemblies and components were purchased from outside suppliers, the plant modified and assembled pleces in stages to complete the mower. The completed mower consisted of fastening two base sections with one motor assembly. The base section fabrication was challenging. It required a pre-cut steel plate to be stamped into a one of the base sections using a heavy press. A fastening kit was then used to bind the steel sections together. The motor assembly was produced by welding a completed motor to an undercarriage. The undercarriage was built with the same fastening kit used for the base section. A completed under carriage required the fastening kit to be combined with a mowing blade. The specialized mowing blade was produced by stamping the same precut steel plate that was used in the base section. There was a quality issue with the supplier of the steel plate last week. An initial inspection revealed that 900 pieces of the steel plate were out of gauge and therefore rejected. Laila contacted the supplier to have them replaced. The replacement shipment was confirmed to come in week 2 of the schedule. Laila reviewed the up to date week ending inventory levels for the mower along with all of its components, subassemblies and their respective lead times. All the relevant data is summarized in the chart below. The items in bold indicate that they are purchased directly from a supplier. The other items are fabricated in the plant. Mower GT 3000 Motor Assembly Base Section Motor Undercarriage Fastening Kit Blade Inventory 400 310 620 750 490 290 115 Lead Time 0 2 3 2 3 2 1 BCIT - APICS 210 1 Steel Plate Custom Industrial Mowers Item Mower GT 3000 Latest Demands 1 2 3 4 5 205 395 100 295 265 300 215 50 600 310 6 7 8 9 10 Case Steps (submit thru the Learning Hub) Activity Steps 1. Design a product structure tree for the entire Bill of Materials. Indicate all levels in production 2. Use a blank MRP sheets fill in all relevant data needed to complete the MRP plan for the next 10 weeks. Note that there are eight different products that need to be planned. 3. Analyze and interpret the data in you MRP plan and comment on your findings. What needs to be done? Make recommendations that would help to avoid future situations. Thint: what can be done immediately and what can be done "moving forward)

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock