Question: please give the answer in more detail because it worth 10% I. Major Facts - What facts could be causing the issue or issues? (Intro)

please give the answer in more detail because it worth 10%

I. Major Facts - What facts could be causing the issue or issues? (Intro)

State here the major facts as you see them. Make statements clear and concise for your own understanding. Consider the implications of the stated facts. Do they point to a problem?

II. Major Problem - What is the key issue to be analyzed? (Intro)

State here the major problem as you see it. Emphasize the present major problem. You may wish to phrase your statement in the form of a question. In a few cases, there may be more than one major problem. A good problem statement will be concise, usually only one sentence.

III. Possible Solutions/Alternatives - What are the options to resolve the key issue or issues? (Body)

A. List here the possible solutions to the major problem. Let your imagination come up with alternative ways to solve the problem.

B. Do not limit yourself to only one or two possible solutions. These solutions should be distinct from each other.

C. However, you may wish to include portions of one solution in another solution, as long as each solution stands alone. Only in this manner will your subsequent choice be definitive.

D. Briefly note advantages and disadvantages of each possible solution.

IV. Choice and Rationale - What would you do? (Body)

State here your choice, A or B or ___ and the detailed reasons for your choice. You may also state your reasons for not choosing the other alternative solutions.

V. Implementation/The Action Plan - How would you implement your plan? How would you track progress of your plans execution? (Body)

Who does what, where, how, when, etc.

and conclusion

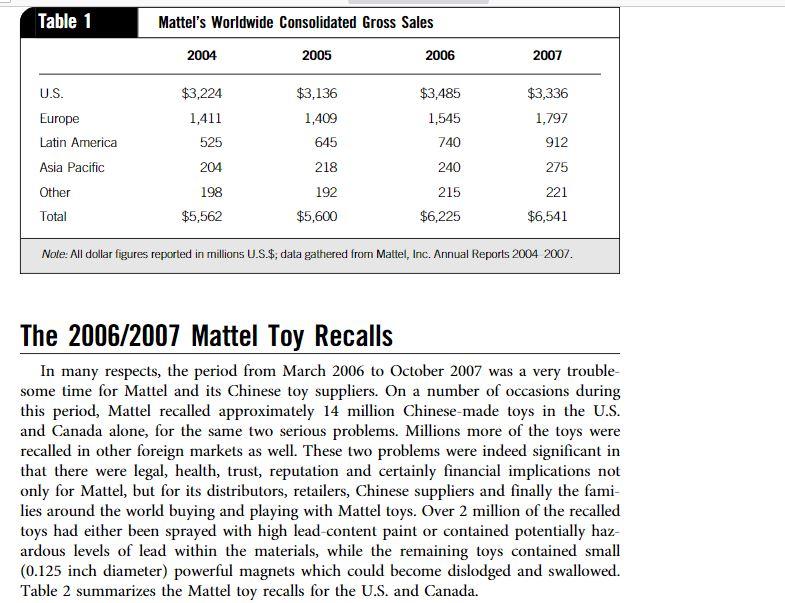

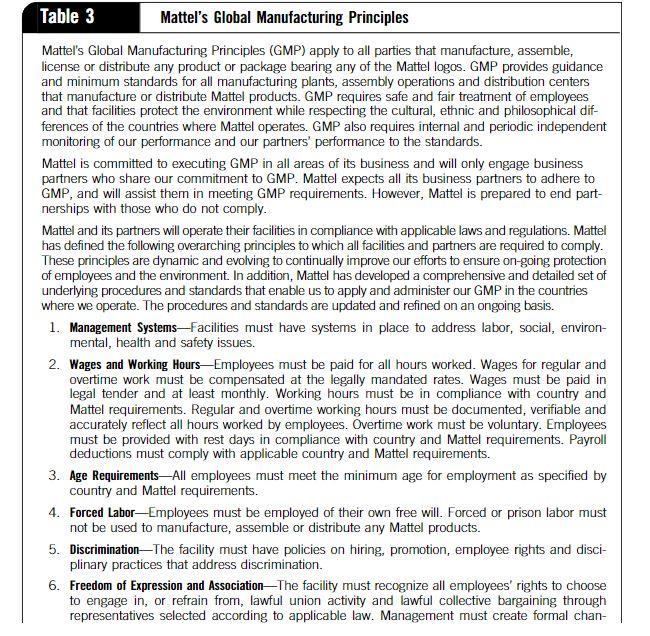

23 The Chinese-Made Toy Recalls at Mattel, Inc. On September 21, 2007 in Beijing China, a meeting took place between Mr. Li Changiang, a top Chinese quality official, Mr. Thomas Debrowski, a senior Mattel executive, and a group of reporters. In what was most certainly a humbling encounter, Mr. Debrowski offered an apology to Chinese toy industry workers and to all of Mattel's worldwide customers who had recently purchased millions of its defective toys. "Mattel takes full responsibility for these recalls and apologizes personally to you, the Chinese people, and all of our customers who received the toys," he said (The Economist, 2007). In fact, Mattel executives and other representatives had been busy for several weeks, apologizing to the U.S. Congress, to Mattel's trading partners, to the American people and to its worldwide customers for the recalls of over 20 million of its toys during the previous 18 months. Managing the business, ethical, legal and political fallout caused by the massive toy recalls had become a very expensive and time-consuming job for Mattel. By late September 2007, employees had logged over 50,000 hours investigating the issues surrounding the toy recalls. The financial losses due to the recalls were large and mountingby the middle of October, Mattel reported spending an estimated U.S. $40 million on product recall-related activities (Farrell 2007). Ultimately for the year, Mattel reported a 4 percent decline in U.S. gross sales, compared to an 11 percent increase the previous year, and the apparent impact from the 2007 toy recalls had reduced gross profits by approximately U.S. $71 million (Mattel Annual Report 2007). Mattel was clearly in a global crisis-management mode. A Brief History of Mattel The company began in 1945 and initially became successful making doll house furniture. Mattel was incorporated in 1947, and by 1955 the toy company's annual sales were U.S. $5 million. In 1959 Mattel introduced the Barbie doll, the best-selling toy of all time, launching the company to the forefront of the toy industry. The firm became publicly held in 1960 , and by 1965 , annual sales topped U.S. $100 million, placing Mattel within the Fortune 500. In 1968, Mattel introduced its Hot Wheels cars, which quickly became the world's number-one die-cast toy vehicles. In that same year, Mattel began acquiring a number of entertainment companies including Ringling Brothers and Barnum \& Bailey Circus, a theme park, a publishing company and a motion picture company. In the early 1970 s, Mattel began experiencing some growth problems. In a move purportedly to appease stockholders, executive vice-president and CFO Seymour Rosenberg 1. Joel D. Wisner, University of Nevada, Las Vegas, College of Business, Department of Management, Las Vegas, Nevada (joel.wisner@unlv.edu). Copyright @2010 by Business Case Journal and the author. Used with permission. This case was prepared solely to provide material for classroom discussion. The author does not intend to illustrate either effective or ineffective handling of a managerial situation. The author has disguised some names and other identifying information to protect confidentiality. The views presented here are those of the case author only. Distribution (Customer) Issues began altering Mattel's books by reporting toy orders as actual sales, even though many began altering Mattel's books by reporting toy orders as actual sales, even though many orders were never filled. This practice of false sales reporting continued for two years until 1973, when Mattel reported an unexpected U.S. $32 million loss, causing a freefall in Mattel's stock price and prompting an investigation by the U.S. Securities and Exchange Commission (SEC). Later that year, original Mattel owner Ruth Handler along with Rosenberg pleaded no contest to SEC charges resulting from the investigation. In 1974 , Rosenberg was fired and Handler was forced to resign. The company reorganized, and returned to profitability in 1977. In the 1980s, Mattel's video games and other non-toy business interests began generating large revenue losses, ultimately resulting in a U.S. $394 million loss in 1983 and placing Mattel in danger of bankruptcy. Several venture capital firms stepped in to save the company in 1984 , and Mattel sold off a number of subsidiaries to concentrate solely on toys. In the latter 1980s, Mattel renewed an earlier collaboration with the Disney Company and began increasing its international presence by acquiring Hong Kongbased toy company ARCO Industries, entering into a joint venture with Japanese toymaker Bandai, and acquiring French doll manufacturer Carolle S.A. and British die-cast toy car maker Corgi Toys Ltd. By the end of the 1980s, Mattel's Barbie doll had become a worldwide phenomenon, accounting for approximately U.S. $1 billion per year in sales, over half of the firm's total worldwide sales at the time. In the 1990s, Mattel's alliance with Disney allowed it to develop and sell toys in Disney theme parks and to sell toys elsewhere based on Disney movie characters. Mattel acquired Fisher-Price, Inc. in 1993. To keep pace with international demand, Mattel began adding manufacturing facilities and sales offices in Indonesia, Austria, Scandinavia and New Zealand. By 1996, the 38 year-old Barbie doll was pulling in U.S. $1.7 billion annually, and in 1997 Mattel completed the acquisition of the world's number-three toy-maker Tyco Toys, Inc. Other acquisitions in the 1990s included Aviva Sports, Inc. and International Games, Inc. In 1998, Mattel was named one of the "100 Best Companies to Work For" by Forbes magazine. The end of the decade, though, was a difficult time for Mattel-its acquisition of the Learning Co. for U.S. $3.5 billion "100 Best Companies to Work For" by Forbes magazine. The end of the decade, though, was a difficult time for Mattel-its acquisition of the Learning Co. for U.S. \$3.5 billion eventually contributed to large unexpected revenue and profit downturns, restructuring charges, job cuts and ultimately the resignation of the company's CEO, Jill Barad. Robert Eckert, formerly head of Kraft Foods, Inc., was named chairman and CEO of Mattel in 2000. The Learning Co. was eventually sold to a corporate turnaround firm, leaving Mattel with a sizeable Learning Co. debt, further losses and liability claims from shareholders alleging mismanagement and breach of fiduciary duty by company executives. Eventually, Mattel was able to streamline its operations, introduce several popular interactive computer games and continue to expand internationally. While some analysts were disappointed with Mattel's single-digit revenue growth during these years, Eckert remained committed to improving the firm's bottom line, rather than concentrating on sales (Mattel Company History, 2002). By the end of 2007, Mattel was selling its toys in over 150 countries, they had more than 30,000 employees worldwide, and had annual gross sales of approximately U.S. $6.5 billion (half of which came from outside the U.S.). Mattel had become the world's largest manufacturer of toy-related products, including dolls, vehicles, playsets and games. Mattel was manufacturing (either directly or through use of contract manufacturers) a whopping 800 million toys per year, and fully two-thirds of these were made in China. Mattel's three largest customers-Wal-Mart, Toys " R " Us and Target-accounted for approximately 40 percent of Mattel's worldwide sales. Table 1 shows Mattel's global gross sales from 2004 to 2007. The 2006/2007 Mattel Toy Recalls In many respects, the period from March 2006 to October 2007 was a very troublesome time for Mattel and its Chinese toy suppliers. On a number of occasions during this period, Mattel recalled approximately 14 million Chinese-made toys in the U.S. and Canada alone, for the same two serious problems. Millions more of the toys were recalled in other foreign markets as well. These two problems were indeed significant in that there were legal, health, trust, reputation and certainly financial implications not only for Mattel, but for its distributors, retailers, Chinese suppliers and finally the families around the world buying and playing with Mattel toys. Over 2 million of the recalled toys had either been sprayed with high lead-content paint or contained potentially hazardous levels of lead within the materials, while the remaining toys contained small (0.125 inch diameter) powerful magnets which could become dislodged and swallowed. Table 2 summarizes the Mattel toy recalls for the U.S. and Canada. On March 30, 2006, approximately 180,000 of Mattel's American Girl jewelry and accessory pieces in the U.S. were recalled by the U.S. Consumer Product Safety Commission (CPSC) because the Chinese-made jewelry contained high levels of lead. On November 21, 2006, following 170 reports of loose magnets on Polly Pocket play sets, the CPSC recalled over 2.4 million of Mattel's Polly Pocket play sets in the U.S. and Canada and another two million were recalled worldwide. In at least three of the reported cases, children had swallowed magnets and suffered serious intestinal perforations requiring surgery and hospitalization. Nine months later on August 2, 2007, almost 1 million of Mattel's Fisher-Price toys were recalled for using paint exceeding the 0.06 percent lead content limit set by the CPSC. Barely two weeks later, the CPSC announced five separate additional recalls of hundreds of thousands of Mattel die cast toy cars for potentially hazardous levels of lead paint and over 9 million play sets in the U.S. and Canada, following hundreds of reports of small magnets falling out of the toys. Immediately following the last of the August recalls, Mattel publicly announced that some of the lead-tainted toys had been painted by a third-party subcontractor working for one of Mattel's primary Asian toy suppliers, Hong Kong-based Early Light Industrial Co., a large toy maker for many of the world's biggest toy companies. Hong Li Da, a Chinese subcontractor used by Early Light, was required to use a Mattel-specified lowlead paint; however, it chose instead to use a less costly, higher lead-content paint from an unapproved supplier. Another Chinese subcontractor, Lee Der Industrial Co., had also used an unauthorized paint supplier when making many of the toys included in the August 2 recall (Zamiska and Casey, 2007). Tragically, one of the co-owners of Lee Der Industrial committed suicide shortly after the August 2 recall announcement (Lindner, 2007). In early September, Mattel announced yet another major recall-over 700,000 units of eleven different toy models for having paint containing excess lead. Finally, on October 25, 2007, still another Mattel recall was announced by the CPSC for Chinesemanufactured toys containing paint with excess lead. In some cases, the Mattel toys had surface paints containing more than 10,000ppm lead or about fifteen times the legal U.S. limit (The Skanner, 2008). All told, Mattel recalled approximately 20 million toys worldwide in 2006 and 2007. According to Mattel spokesperson Michele Sturdivant, "If these vendors and their subcontractors had adhered to our procedures, we wouldn't have this issue. We have instituted changes to our required procedures to catch cases of our policies not being adhered to, and to improve accountability" (Sun, 2007). Mattel typically performed monthly audits of manufacturers' toys, which sometimes included testing random units and other times involved reviewing manufacturers' testing records. Jim Walter, Mattel's senior vice president of worldwide quality assurance, explained, "They didn't perform the testing they should have, and the audit we performed didn't catch it" (Spencer and Casey, 2007). Mattel's Responses to the Recalls In mid-August 2007, Mattel CEO Robert Eckert filmed a video apology to parents, placing it on the company's and on Yahoo's website. "I can't change what has happened in the past, but I can change how we work in the future," he said, adding that he had four children of his own. Mattel pledged to increase the frequency of its paint inspections, testing every batch delivered to every supplier. The firm purchased full-page explanatory ads in the New York Times, USA Today and Wall Street Journal. "Nothing is more important than the safety of our children," began the letter. "Our long record of safety at Mattel is why we're one of the most trusted names with parents," it continued. The letter went on to identify Early Light Industrial, which Eckert described as a victim along with Mattel of Hong Li Da and Lee Der Industrial, the producers of many of the lead-tainted toys (Barboza and Story, 2007). Following the third-quarter 2007 recalls, Mattel slowed down the shipments coming out of Asia to conduct product testing and safety reviews. Similarly, Mattel's shipments of finished product to global markets were curtailed while various regulatory authorities reviewed Mattel's safety procedures. Ultimately, Mattel was able to prevent more than two-thirds of the recalled toys from reaching consumers by contacting and warning distribution centers and retailers (Schuman, 2007). On September 5, 2007, Mattel representatives told an American congressional committee that the problem with toys containing small loose magnets was the result of Mattel's own flawed toy designs, and not due to any lack of adherence to manufacturing requirements in China. According to Mattel CEO Eckert, "We apologize again to everyone affected and promise that we will continue to focus on ensuring the safety and quality of our toys" (Steverman, 2007). Following the apology of Mattel's Mr. Debrowski on September 21 in Beijing, Mr. Li, the Chinese quality official, told reporters that the Chinese government had shut down operations and revoked the business license of Lee Der Industrial, one of the subcontractors producing the lead-tainted Mattel toys. With regard to the unsafe magnet problem, Mattel made several manufacturing changes to better retain magnets in its toys, including longer cure times for adhesives, the use of additional adhesive and the use of injection molding to better encapsulate magnets inside the toys. A timeline of the toy recalls and Mattel's responses to them is shown in Figure 1. Most of the recalled toy export/import issues were resolved by the end of 2007 . Mattel decided to continue using the Early Light, since they had been a trusted supplier for Most of the recalled toy export/import issues were resolved by the end of 2007 . Mattel decided to continue using the Early Light, since they had been a trusted supplier for more than fifteen years. As a result of the recalls, Mattel created a Corporate Responsibility division, which had accountability internally and externally for adherence to company safety and compliance procedures (Mattel Annual Report, 2007). New policies were instituted requiring all direct suppliers to conduct quality tests on all of their incoming materials as well as finished toys made by any of their subcontractors. The Chinese Manufacturing and Regulatory Environments To discuss Chinese toy manufacturing and the regulatory environment impacting Mattel, it is necessary first to move back in time to 1995. U.S. trade with foreign toy manufacturers changed quite dramatically in 1995, when U.S. duties on all imported toys were completely eliminated as a result of the World Trade Organization (WTO) agreement. When China joined the WTO in 2001 and was granted permanent "normal trade relations" status along with several other Asian countries under U.S. tariff laws enacted in 2002 , China with its millions of available low-wage workers suddenly became an attractive alternative for Mattel's toy manufacturing operations. At the end of 2007 , the legal minimum wage for factory workers in China was 4.02 yuan RMB (about U.S. \$0.57) per hour. While technically the workweek in China A Discussion of buyer-suppiler kelationsinips Mattel and Early Light had been doing business together for over fifteen years. Apparently, this relationship created enough value for both trading partners to justify this long-term trading relationship. The notion of managing relationships with suppliers to create value-enhancing long-term partnerships has become quite popular in recent years as the practice has become widely accepted as a major component of supply chain management. The Council of Supply Chain Management Professionals (CSCMP) defines supply chain management as "[t]he planning and management of all activities involved in sourcing and procurement, conversion and all logistics management activities. Importantly, it also includes coordination and collaboration with channel partners, which can be suppliers, intermediaries, third-party service providers and customers" (CSCMP website). The objective of supply chain management is to improve operating efficiencies, quality and customer service through collaboration, to create sustainable competitive advantage for the supply chain participants and better, cheaper products for the final consumers. Supply chain management and its constituent parts-supplier relationship management, inventory and quality management, and customer relationship management - have been widely researched over the past twenty years, are discussed in was 40 hours, workers typically worked more than 60 hours per week. Six workdays per week was very common. In a few short years and with the help of Mattel and other toy companies, China had quickly become the world's primary toy producer. At the time of this case, for example, China's Guangdong province, about the size of Florida, contained more than 5,000 toy factories and employed about one-third of China's migrant factory workers (Newsgd.com, 2008). Companies operating in China were subject to very few regulations, and had little legal recourse when problems arose. Foreign firms operating in China tried to protect themselves by securing guarantees from Chinese suppliers that they would follow specific procedures. Unfortunately, these procedures were almost impossible to enforce. In September 2007, Yan Jiangying of the Chinese State Food and Drug Association admitted that "supervisory foundations are still very weak." The oversight of food safety, for instance, was split between five ministries, resulting in overlapping and unclear responsibilities. Further, there was almost no history of regulatory compliance for Chinese businesses; consequently, many safety and quality shortcuts tended to be taken when suppliers were pressured by their customers to reduce prices. In many cases, Chinese suppliers felt forced to put pressure on their own suppliers to reduce prices, occasionally with the disastrous results seen in this case and in others, such as the instances of unsafe Chinese pet food in 2007 and contaminated Chinese milk in 2008. With respect to lead paint use, China had laws banning high lead-content paint from consumer products, but lax regulatory enforcement meant these laws were routinely ignored. For example, in a test conducted by the University of Cincinnati from 2004 to 2007, 38 Chinese paint samples representing 11 different brands were tested, and more than 25 percent were found to contain lead levels exceeding the U.S. safe limit of 0.06 percent. Fast-food operator McDonald's Corp., one of the world's largest toy buyers, said the problem of high lead-content paint in China was so widespread, their company was forced to monitor paint quality all the way back to the original paint suppliers (Spencer and Casey, 2007). Ironically, Chinese cultural norms were often at odds with the way some companies were managed, as noted earlier with the suicide of Lee Der Industrial's co-owner. Another example of this can be seen in a Chinese news item from about the same time period-Zheng Xiaoyu, a Chinese State Food and Drug Administration official who took bribes totaling more than U.S. $800,000 to approve the export of medicines tainted with toxic materials, was convicted and executed. Cao Wenzhuang, one of Zheng's department directors, received life in prison for taking bribes of about U.S. $300,000 (Caldwell, 2007 and Trunick, 2007). For a number of years, Mattel had used the New York-based International Center for Corporate Accountability (ICCA), a nonprofit research organization, to conduct audits of its company-managed and third-party Chinese manufacturers to insure compliance with Mattel's Global Manufacturing Principles (GMP), shown in Table 3. Chinese plant managers were required to complete GMP compliance reports prior to actual field audits. Audits consisted of a firm's accounting practices; confidential one-on-one interviews with employees; an examination of the plant's policies, procedures and practices with regard to the environment; employee health and safety issues; inspections of the general maintenance of the manufacturing facilities; storage, treatment and disposal of hazardous waste materials; hygiene issues; and dormitories and recreational facilities. The ICCA provided post-audit reports to Mattel, whereby corrective actions were taken in response to the findings (Mattel website, 2007). Table 3 Mattel's Global Manufacturing Principles Mattel's Global Manufacturing Principles (GMP) apply to all parties that manufacture, assemble, license or distribute any product or package bearing any of the Mattel logos. GMP provides guidance and minimum standards for all manufacturing plants, assembly operations and distribution centers that manufacture or distribute Mattel products. GMP requires safe and fair treatment of employees and that facilities protect the environment while respecting the cultural, ethnic and philosophical differences of the countries where Mattel operates. GMP also requires internal and periodic independent monitoring of our performance and our partners' performance to the standards. Mattel is committed to executing GMP in all areas of its business and will only engage business partners who share our commitment to GMP. Mattel expects all its business partners to adhere to GMP, and will assist them in meeting GMP requirements. However, Mattel is prepared to end partnerships with those who do not comply. Mattel and its partners will operate their facilities in compliance with applicable laws and regulations. Mattel has defined the following overarching principles to which all facilities and partners are required to comply. These principles are dynamic and evolving to continually improve our efforts to ensure on-going protection of employees and the environment. In addition, Mattel has developed a comprehensive and detailed set of underlying procedures and standards that enable us to apply and administer our GMP in the countries where we operate. The procedures and standards are updated and refined on an ongoing basis. 1. Management Systems-Facilities must have systems in place to address labor, social, environmental, health and safety issues. 2. Wages and Working Hours - Employees must be paid for all hours worked. Wages for regular and overtime work must be compensated at the legally mandated rates. Wages must be paid in legal tender and at least monthly. Working hours must be in compliance with country and Mattel requirements. Regular and overtime working hours must be documented, verifiable and accurately reflect all hours worked by employees. Overtime work must be voluntary. Employees must be provided with rest days in compliance with country and Mattel requirements. Payroll deductions must comply with applicable country and Mattel requirements. 3. Age Requirements-All employees must meet the minimum age for employment as specified by country and Mattel requirements. 4. Forced Labor-Employees must be employed of their own free will. Forced or prison labor must not be used to manufacture, assemble or distribute any Mattel products. 5. Discrimination-The facility must have policies on hiring, promotion, employee rights and disciplinary practices that address discrimination. 6. Freedom of Expression and Association-The facility must recognize all employees' rights to choose to engage in, or refrain from, lawful union activity and lawful collective bargaining through representatives selected according to applicable law. Management must create formal chan- As global competition increases, companies are pressured to focus more on their key competitive strengths while outsourcing many other operational activities. Companies today believe strongly that developing win-win supplier relationships is critical to achieving long-term success. According to Kenichi Ohmae, globally acclaimed speaker and founder of Japan-based Ohmae \& Associates, "Companies are just beginning to learn what nations have always known: in a complex world filled with dangerous opponents, it is best not to go it alone" (Ohmae, 1989). Trust is critical for any buyer-supplier partnership to succeed. Trust has often been shown to be the outcome of the ability of a firm to meet its customers' requirements (see, for instance, Doney and Cannon, 1997; Chaudhuri and Holbrook, 2001). Accordingly, trust is a central attribute in relationship initiation, formation and management and has been found to be directly linked to customer loyalty (Sirdeshmukh, Singh and Sabol, 2002). When trust between trading partners exists, collaboration can occur. Collaboration in supply chains refers to the sharing of information and the pooling of resources to achieve an objective. In many cases, collaboration has been shown to provide positive benefits to both the buyer and supplier (see, for example, Jap, 1999; Corsten and Felde, 2005; Lam et al., 2007). Trust and collaboration are seen as the two key requirements for buyer-supplier relationship success. Ethical and Legal Considerations In the U.S., Mattel's toys are subject to provisions of the Consumer Product Safety Act, the Federal Hazardous Substances Act, the Flammable Fabrics Act, and the Food, Drug and Cosmetics Act. The Consumer Product Safety Commission (CPSC) can exclude products from the U.S. market for failing to comply with applicable regulations or that otherwise create a substantial risk of injury, including items containing excessive amounts of hazardous substances. The CPSC may require the recall, repurchase, replacement or repair of items (Mattel Annual Report, 2007). Additionally, U.S. Customs \& Border Protection (CRD) eneures that anode enterina the It S are cafe for concumere The CRD has the In the U.S., Mattel's toys are subject to provisions of the Consumer Product Safety Act, the Federal Hazardous Substances Act, the Flammable Fabrics Act, and the Food, Drug and Cosmetics Act. The Consumer Product Safety Commission (CPSC) can exclude products from the U.S. market for failing to comply with applicable regulations or that otherwise create a substantial risk of injury, including items containing excessive amounts of hazardous substances. The CPSC may require the recall, repurchase, replacement or repair of items (Mattel Annual Report, 2007). Additionally, U.S. Customs \& Border Protection (CBP) ensures that goods entering the U.S. are safe for consumers. The CBP has the authority to detain and exclude any products based on instructions from the CPSC. The CPSC initiated all of the Mattel toy recalls previously shown in Table 2. Mattel was facing public relations, ethical and legal problems following the 2006 and 2007 toy recalls. According to Fred Perez, vice president of claims services for McLarens Young International, a global claims management service, Mattel was ultimately effective at minimizing its liability damages, with only about 30 percent of the recalled toys actually making it to retail outlets. "The actual exposure is not great. This is more of a public relations nightmare for Mattel," said Perez. While these and other recent recall troubles could have created a "suspicion about importing products, especially from China," Perez claimed there would likely not be any major long-term implications for Chinese manufacturers. "China is too big a market for manufacturers to abandon," he said (Brady, 2007). Doug Hart, a law partner at New York-based BDO Seidman, who follows the toy industry, echoed Perez's public relations warning. "This could be the time that consumer perception begins to change in relation to Mattel and Barbie," he said (Casey and Zamiska, 2007). On August 20, 2007, a class-action lawsuit was filed in Los Angeles County Superior Court against Mattel, regarding the toys with high lead-content paint. This lawsuit sought to have Mattel establish a fund so that parents could be reimbursed for testing their children for lead poisoning (the cost to test for lead poisoning is approximately U.S. $50 per person). On September 4, 2007, the CPSC began investigating whether Mattel knowingly withheld information regarding any safety risks posed by the millions of toys recalled. Mattel could be substantially fined if it is found in violation of the Consumer Product Safety Act of 1972, which stipulates that companies must inform the CPSC within 24 hours when they obtain product defect information that could create a health hazard. Finally, a second class-action lawsuit was filed against Mattel on September 27, 2007 in California, seeking damages for injuries suffered from swallowing magnets improperly attached to Mattel toy sets (Luk and Wong, 2007). The Global Toy Industry Response In the U.S. alone, there were a total of 72 toy recalls in 2007 involving the U.S. toy industry. Fifty of these recalls were for Chinese-made toys with high lead-content paint. These recalls by Mattel and other toy manufacturers highlighted the need for stricter toy quality and safety controls and raised awareness throughout the global toy industry of the need to reassure consumers about the safety of toys. By the end of 2007 , several initiatives had already been instituted. The British Toy and Hobby Association, for example, added a new parent's webpage for safety reassurance. Organizations such as the Toy Industries of Europe, Toy Industries of America, American National Standards Institute, U.S. CPSC and the European Commission began working together to produce an international audit system for the safety processes of toy manufacturers. According to spokesperson Bryan Ellis, "This is a serious and genuine attempt to create a global standard. The industry takes this very seriously" (Collins, 2007). In the U.S., laws regarding toy safety were becoming tougher in large part because of the many toy recalls of 2007. On December 17, 2007 the U.S. Congress voted unanimously to approve the Consumer Product Safety Modernization Act to further reduce the acceptable lead levels in toy paints and to require independent third-party testing of all toys. By the end of 2007, the Chinese toy industry was struggling. In Foshan, a major Chinese toy manufacturing hub in Guangdong province, some companies were tightening standards and increasing testing to reassure their Western buyers. Others were closing down or looking for less regulated markets. "It's very difficult to do business now," said Ms. Deng Xiling, sales manager at a factory making plastic components for toys. Her company closed its painted-toy division following the Mattel toy recalls and laid off almost one-third of its workforce because they could not afford the types of product testing Western buyers started requiring. Stanley Wong, vice president of Foshan Dayi Toy Co. said their firm was raising prices by 10 ten percent to cover the increased testing required by their customers, which included Mattel and Wal-Mart. Other companies in Foshan also began raising prices. "In the past, customers bringing in small orders usually had no requirements on testing," explained one toy company executive. "Now they want testing for every piece." The Lee Der Co., a major player in Mattel's August 2007 toy recalls, was shut down entirely (Fairclough, 2007). Some of the issues surrounding this case remained to be resolved. A Final Assessment Mattel executive managers such as CEO Robert Eckert, senior executive Thomas Debrowski and VP of worldwide quality Jim Walter were left to ponder the primary causes of Mattel's recall problems, its responses to the problems and the proper steps going forward to assure no similar problems occurred again. How could a multi-billion dollar global giant like Mattel have possibly allowed all of this to happen? Over a period of nineteen months Mattel recalled approximately 20 million toys worldwide. The company was subjected to numerous lawsuits and regulatory actions, and suffered sales and profit losses along with significant damage to its reputation. Two issues were involved: excessive levels of lead in numerous toy surface paints because Chinese subcontractors used unapproved paint; and small unsecured magnets in toys that could be swallowed, caused by faulty Mattel toy designs. Because of the two problems, many Chinese toy manufacturers and their suppliers were either put out of business entirely or lost significant business; toy distributors, retailers and logistics companies had potentially incurred additional costs to manage the millions of recalled toys; parents had become more concerned about toy safety and buying Mattel toys; and children had been and might still be harmed. Had Mattel's management taken the proper precautions with its Chinese operations and contract suppliers? Were their problems unavoidable, as in "the cost of doing business in developing countries"? Did Mattel respond quickly enough and appropriately once the problems began? How might Mattel's management address the ethical, legal and reputation issues going forward? And finally, were the rewards Mattel garnered by doing business in China worth the risks and problems involvedStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts