Question: Please go through the Review Article and submit a summary of 500-800 words to include. a. Focal points discussed regarding SCM. b. Important issues and

Please go through the Review Article and submit a summary of 500-800 words to include.

a. Focal points discussed regarding SCM.

b. Important issues and challenges concerning supply chain management.

c. Important conclusion drawn for improving overall supply chain performance.

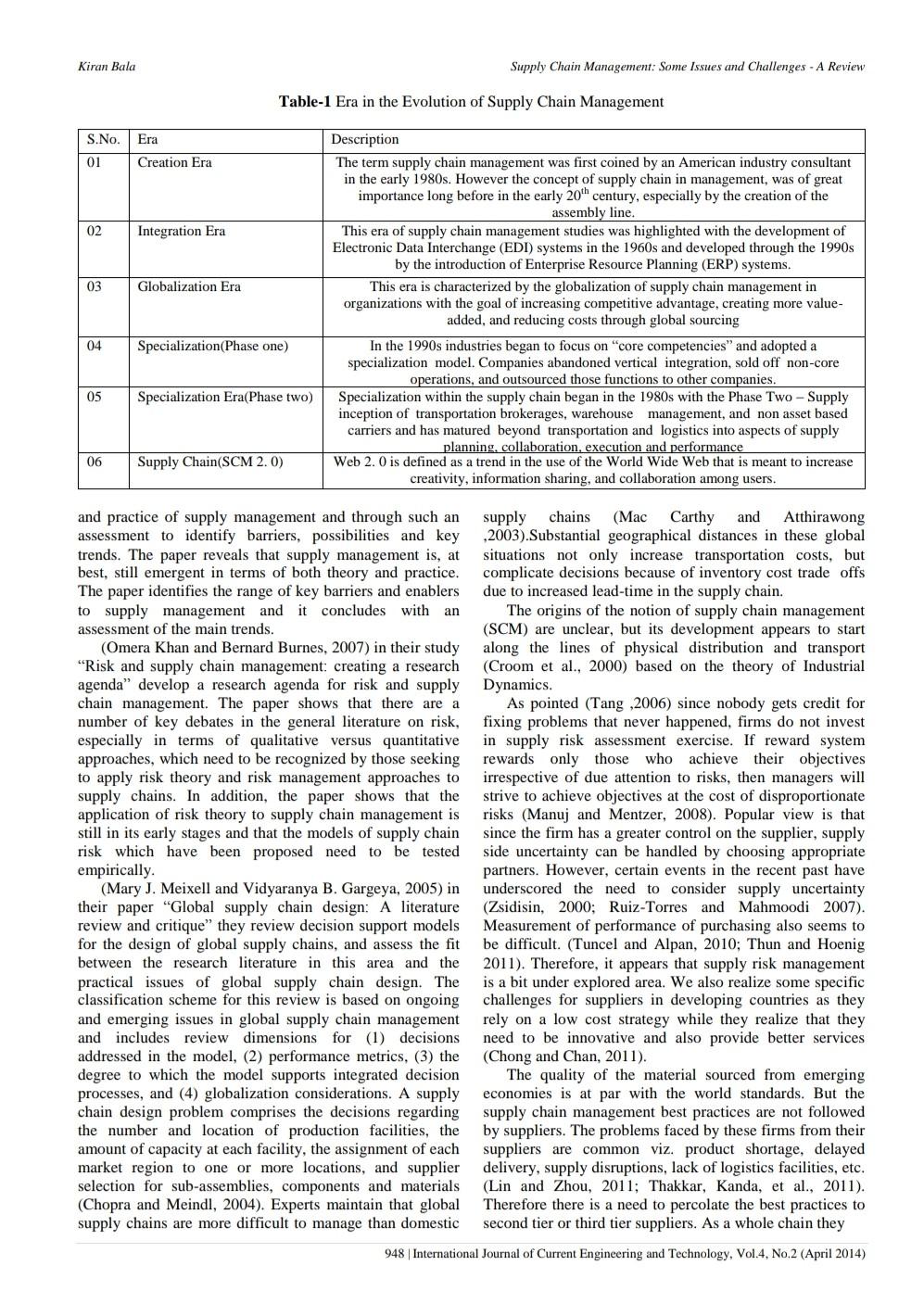

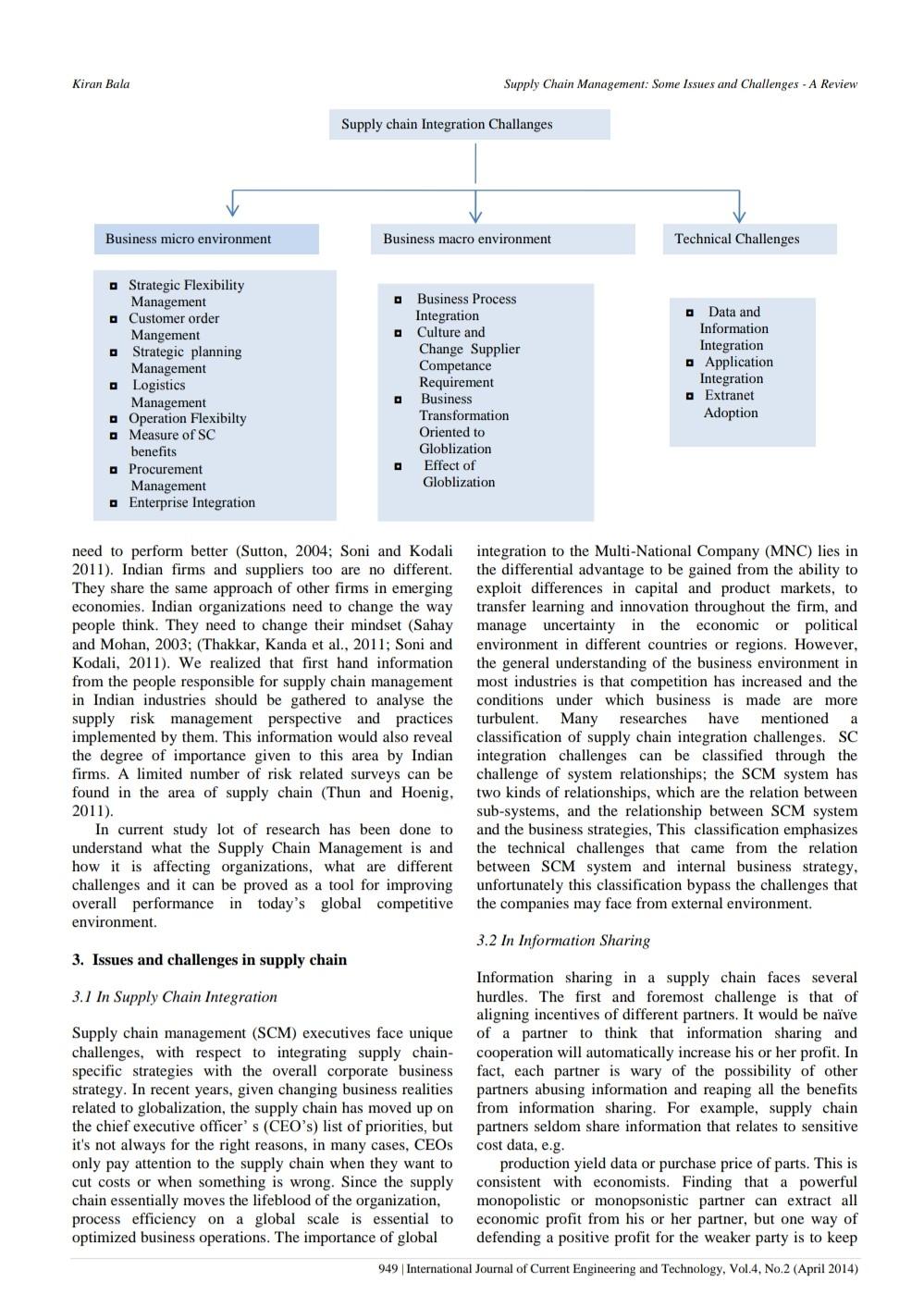

Abstract India is becoming a global manufacturing hub. Increasing demand in domestic and international markets is opening a new world of opportunities for the Indian Industry. Increasing competition, due to globalization is making inevitable for the Indian industries to provide cost effective quality output with stringent delivery schedules. Issues in supply of inferior quality, delayed supply, unwarranted cost escalation, etc. would adversely impact the credibility and business potential of the Indian industry. Amongst many difficulties faced by Indian manufacturers, supply chain disruption management is a major issue, which can result in large tangible and non-tangible losses. In current study lot of research has been done to understand what the Supply Chain Management is and how it is affecting organizations, what are different challenges and it can be proved as a tool for improving overall performance in today's global competitive environment. Keywords: Supply chain management. 1. Introduction his suppliers and through his suppliers' suppliers and so on back. By having the program driven by the customer, it is In the current competitive scenario supply chain hoped that inventories, caused by uncertainties and slow management assumes a significant importance and calls response, will be significantly eliminated. While there are for serious research attention, as companies are challenged sales incentives to major suppliers with the carrot of with finding ways to meet ever-rising customer category management or similar programs, the success of expectations at a manageable cost. To do so, businesses supply chain management rests with logistics. must search out which parts of their supply-chain process are not competitive, understand which customer needs are Functional areas of Logistics: not being met, establish improvement goals, and rapidly 1. Network Design implementnecessaryimprovements.2.InformationTechnology The term 'supply chain management' has not only 3. Transportation been used to explain the logistics activities and the 4. Inventory and Storage planning and control of materials and information flows 5. Warehousing internally within a company or externally between 6. Materials Handling, Loading and unloading companies (Christopher 1992, Cooper et al.,1997 and 7. Packaging and Re-packaging Fisher, 1997). Researchers have also used it to describe strategic, inter organizational issues (Cox, 1997, Harland It should be noted that supply chain management has both et al., 1999), to discuss an alternative organizational form "hard" (i.e., technical) and "soft" (i.e., people) aspects, to vertical integration (Thorelli ,1986 Hakansson and reflecting the fact that the field is at the intersection of Snehota, 1995), to identify and describe the relationship a many disciplines, such as marketing, procurement, company develops with its suppliers (Helper, 1991and management, operations research, logistics, and so on. It Hines, 1994, Narus and Anderson, 1995), and to address might be supposed that social network analysis the purchasing and supply perspective (Morgan and originating as it does in social psychology - would have Monczka, 1996 and Farmer, 1997). its greatest and most natural application on the soft side of Supply Chain Management is a reverse of prior SCM, helping to understand how patterns of personal practices where manufacturers supplied product to relationships translate to competitive advantage through customers. Now customers tell suppliers how and when diffusion of information, social control of opportunism, they want their inventory delivered. The driver behind coordination and aid and so on (Stephen P. and Xunli, Supply Chain Management is to remove inefficiencies, 2009). excess costs and excess inventories from the supply The initial benefits of supply chain management accrue pipeline which extends from the customer back through to the customer, the initiator of his supply chain. He earns the reduction in inventories by driving out excesses *Corresponding author is a Research Scholar inventories which he must purchase, store and be 946 International Journal of Current Engineering and Technology. Vol.4. No.2 (April 2014) Kiran Bala Supply Chain Management: Some Issues and Challenges - A Review Table-1 Era in the Evolution of Supply Chain Management and practice of supply management and through such an supply chains (Mac Carthy and Atthirawong assessment to identify barriers, possibilities and key ,2003).Substantial geographical distances in these global trends. The paper reveals that supply management is, at situations not only increase transportation costs, but best, still emergent in terms of both theory and practice. complicate decisions because of inventory cost trade offs The paper identifies the range of key barriers and enablers due to increased lead-time in the supply chain. to supply management and it concludes with an The origins of the notion of supply chain management assessment of the main trends. (SCM) are unclear, but its development appears to start (Omera Khan and Bernard Burnes, 2007) in their study along the lines of physical distribution and transport "Risk and supply chain management: creating a research (Croom et al., 2000) based on the theory of Industrial agenda" develop a research agenda for risk and supply Dynamics. chain management. The paper shows that there are a As pointed (Tang ,2006) since nobody gets credit for number of key debates in the general literature on risk, fixing problems that never happened, firms do not invest especially in terms of qualitative versus quantitative in supply risk assessment exercise. If reward system approaches, which need to be recognized by those seeking rewards only those who achieve their objectives to apply risk theory and risk management approaches to irrespective of due attention to risks, then managers will supply chains. In addition, the paper shows that the strive to achieve objectives at the cost of disproportionate application of risk theory to supply chain management is risks (Manuj and Mentzer, 2008). Popular view is that still in its early stages and that the models of supply chain since the firm has a greater control on the supplier, supply risk which have been proposed need to be tested side uncertainty can be handled by choosing appropriate empirically. partners. However, certain events in the recent past have (Mary J. Meixell and Vidyaranya B. Gargeya, 2005) in underscored the need to consider supply uncertainty their paper "Global supply chain design: A literature (Zsidisin, 2000; Ruiz-Torres and Mahmoodi 2007). review and critique" they review decision support models Measurement of performance of purchasing also seems to for the design of global supply chains, and assess the fit be difficult. (Tuncel and Alpan, 2010; Thun and Hoenig between the research literature in this area and the 2011). Therefore, it appears that supply risk management practical issues of global supply chain design. The is a bit under explored area. We also realize some specific classification scheme for this review is based on ongoing challenges for suppliers in developing countries as they and emerging issues in global supply chain management rely on a low cost strategy while they realize that they and includes review dimensions for (1) decisions need to be innovative and also provide better services addressed in the model, (2) performance metrics, (3) the (Chong and Chan, 2011). degree to which the model supports integrated decision The quality of the material sourced from emerging processes, and (4) globalization considerations. A supply economies is at par with the world standards. But the chain design problem comprises the decisions regarding supply chain management best practices are not followed the number and location of production facilities, the by suppliers. The problems faced by these firms from their amount of capacity at each facility, the assignment of each suppliers are common viz. product shortage, delayed market region to one or more locations, and supplier delivery, supply disruptions, lack of logistics facilities, etc. selection for sub-assemblies, components and materials (Lin and Zhou, 2011; Thakkar, Kanda, et al., 2011). (Chopra and Meindl, 2004). Experts maintain that global Therefore there is a need to percolate the best practices to supply chains are more difficult to manage than domestic second tier or third tier suppliers. As a whole chain they 948 International Journal of Current Engineering and Technology, Vol.4, No.2 (April 2014) Kiran Bala Supply Chain Management: Some Issues and Challenges - A Review need to perform better (Sutton, 2004; Soni and Kodali integration to the Multi-National Company (MNC) lies in 2011). Indian firms and suppliers too are no different. the differential advantage to be gained from the ability to They share the same approach of other firms in emerging exploit differences in capital and product markets, to economies. Indian organizations need to change the way transfer learning and innovation throughout the firm, and people think. They need to change their mindset (Sahay manage uncertainty in the economic or political and Mohan, 2003; (Thakkar, Kanda et al., 2011; Soni and environment in different countries or regions. However, Kodali, 2011). We realized that first hand information the general understanding of the business environment in from the people responsible for supply chain management most industries is that competition has increased and the in Indian industries should be gathered to analyse the conditions under which business is made are more supply risk management perspective and practices turbulent. Many researches have mentioned a implemented by them. This information would also reveal classification of supply chain integration challenges. SC the degree of importance given to this area by Indian integration challenges can be classified through the firms. A limited number of risk related surveys can be challenge of system relationships; the SCM system has found in the area of supply chain (Thun and Hoenig, two kinds of relationships, which are the relation between 2011). sub-systems, and the relationship between SCM system In current study lot of research has been done to and the business strategies, This classification emphasizes understand what the Supply Chain Management is and the technical challenges that came from the relation how it is affecting organizations, what are different between SCM system and internal business strategy, challenges and it can be proved as a tool for improving unfortunately this classification bypass the challenges that overall performance in today's global competitive the companies may face from external environment. environment. 3.2 In Information Sharing 3. Issues and challenges in supply chain Information sharing in a supply chain faces several 3.1 In Supply Chain Integration hurdles. The first and foremost challenge is that of aligning incentives of different partners. It would be nave Supply chain management (SCM) executives face unique of a partner to think that information sharing and challenges, with respect to integrating supply chain- cooperation will automatically increase his or her profit. In specific strategies with the overall corporate business fact, each partner is wary of the possibility of other strategy. In recent years, given changing business realities partners abusing information and reaping all the benefits related to globalization, the supply chain has moved up on from information sharing. For example, supply chain the chief executive officer' s (CEO's) list of priorities, but partners seldom share information that relates to sensitive it's not always for the right reasons, in many cases, CEOs cost data, e.g. only pay attention to the supply chain when they want to production yield data or purchase price of parts. This is cut costs or when something is wrong. Since the supply consistent with economists. Finding that a powerful chain essentially moves the lifeblood of the organization, monopolistic or monopsonistic partner can extract all process efficiency on a global scale is essential to economic profit from his or her partner, but one way of optimized business operations. The importance of global defending a positive profit for the weaker party is to keep

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts