Question: Please hand write and draw it. Stream data for a chemical process are given in Table 1.1. A Maximum Energy Recovery Heat Exchanger Network (MER

Please hand write and draw it.

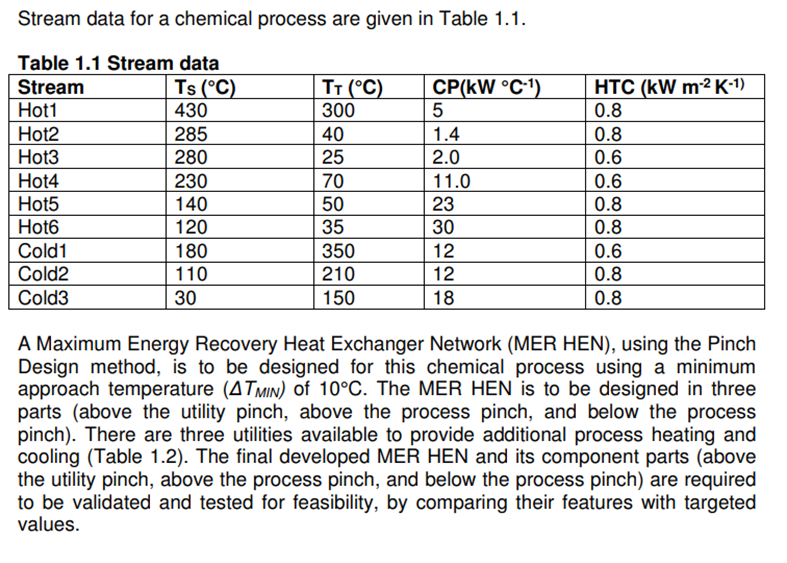

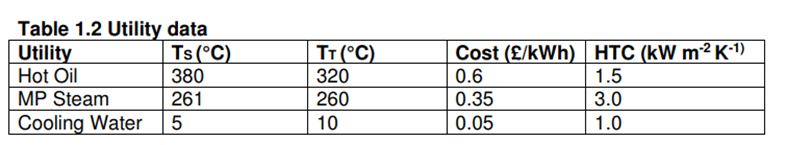

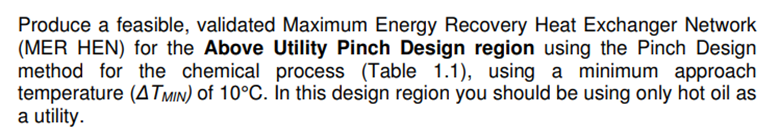

Stream data for a chemical process are given in Table 1.1. A Maximum Energy Recovery Heat Exchanger Network (MER HEN), using the Pinch Design method, is to be designed for this chemical process using a minimum approach temperature (TMIN) of 10C. The MER HEN is to be designed in three parts (above the utility pinch, above the process pinch, and below the process pinch). There are three utilities available to provide additional process heating and cooling (Table 1.2). The final developed MER HEN and its component parts (above the utility pinch, above the process pinch, and below the process pinch) are required to be validated and tested for feasibility, by comparing their features with targeted values. Tahlo 19 Iltility data Produce a feasible, validated Maximum Energy Recovery Heat Exchanger Network (MER HEN) for the Above Utility Pinch Design region using the Pinch Design method for the chemical process (Table 1.1), using a minimum approach temperature (TMIN) of 10C. In this design region you should be using only hot oil as a utility. Stream data for a chemical process are given in Table 1.1. A Maximum Energy Recovery Heat Exchanger Network (MER HEN), using the Pinch Design method, is to be designed for this chemical process using a minimum approach temperature (TMIN) of 10C. The MER HEN is to be designed in three parts (above the utility pinch, above the process pinch, and below the process pinch). There are three utilities available to provide additional process heating and cooling (Table 1.2). The final developed MER HEN and its component parts (above the utility pinch, above the process pinch, and below the process pinch) are required to be validated and tested for feasibility, by comparing their features with targeted values. Tahlo 19 Iltility data Produce a feasible, validated Maximum Energy Recovery Heat Exchanger Network (MER HEN) for the Above Utility Pinch Design region using the Pinch Design method for the chemical process (Table 1.1), using a minimum approach temperature (TMIN) of 10C. In this design region you should be using only hot oil as a utility

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts