Question: Please help answer all, step by step with the excel solutions. Want to learn how it's done thank you, will give you a like! Sanders

Please help answer all, step by step with the excel solutions. Want to learn how it's done thank you, will give you a like!

Please help answer all, step by step with the excel solutions. Want to learn how it's done thank you, will give you a like!

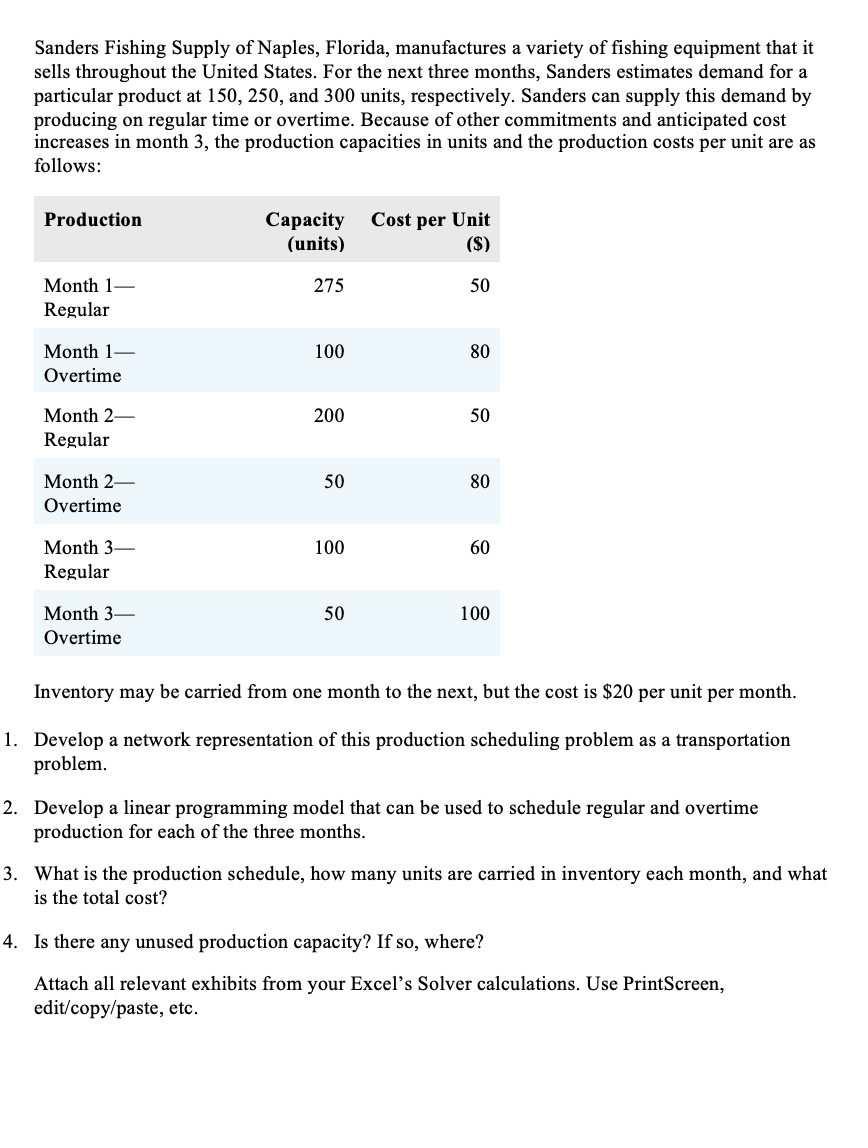

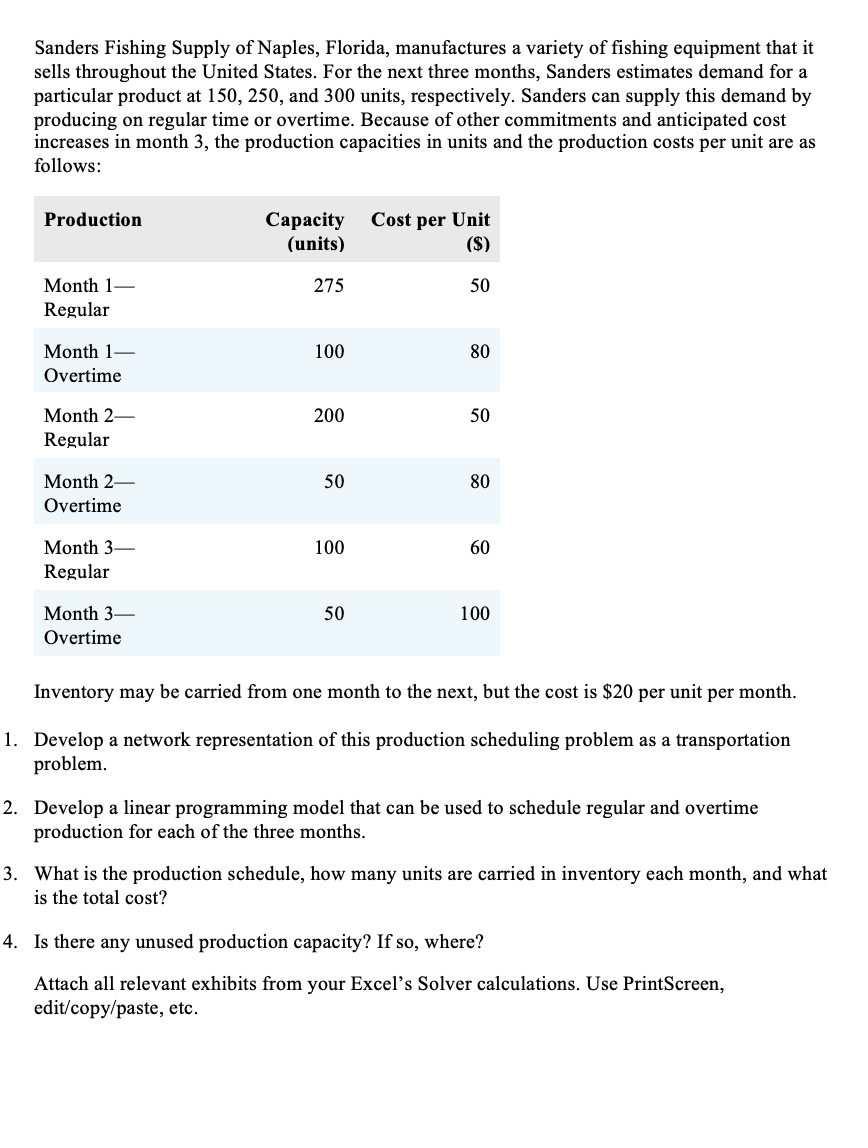

Sanders Fishing Supply of Naples, Florida, manufactures a variety of fishing equipment that it sells throughout the United States. For the next three months, Sanders estimates demand for a particular product at 150, 250, and 300 units, respectively. Sanders can supply this demand by producing on regular time or overtime. Because of other commitments and anticipated cost increases in month 3, the production capacities in units and the production costs per unit are as follows: Production Capacity (units) Cost per Unit (S) 275 50 Month 1- Regular 100 80 Month 1 Overtime 200 50 Month 2- Regular 50 80 Month 2- Overtime 100 60 Month 3- Regular 50 100 Month 3 Overtime Inventory may be carried from one month to the next, but the cost is $20 per unit per month. 1. Develop a network representation of this production scheduling problem as a transportation problem. 2. Develop a linear programming model that can be used to schedule regular and overtime production for each of the three months. 3. What is the production schedule, how many units are carried in inventory each month, and what is the total cost? 4. Is there any unused production capacity? If so, where? Attach all relevant exhibits from your Excel's Solver calculations. Use PrintScreen, edit/copy/paste, etc

Please help answer all, step by step with the excel solutions. Want to learn how it's done thank you, will give you a like!

Please help answer all, step by step with the excel solutions. Want to learn how it's done thank you, will give you a like!