Question: Please help explain below especially the Figure 1, Figure 2, Figure 3, and Figure 4. Thanks! Optimizing the Digital Camera Business Digital imaging is a

Please help explain below especially the Figure 1, Figure 2, Figure 3, and Figure 4. Thanks!

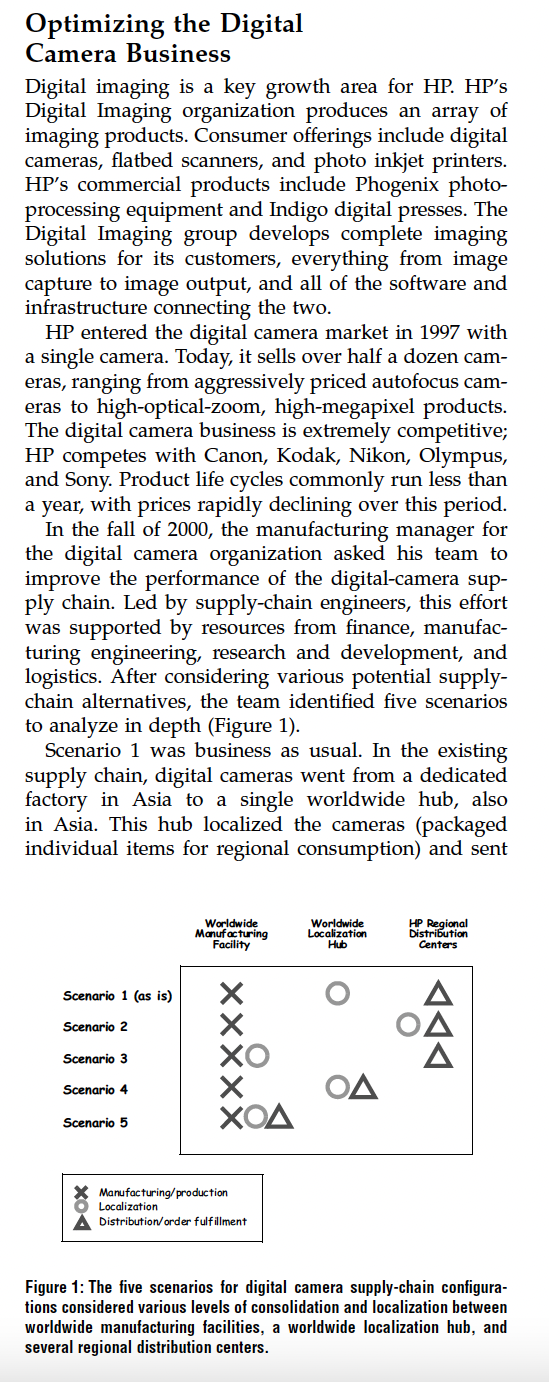

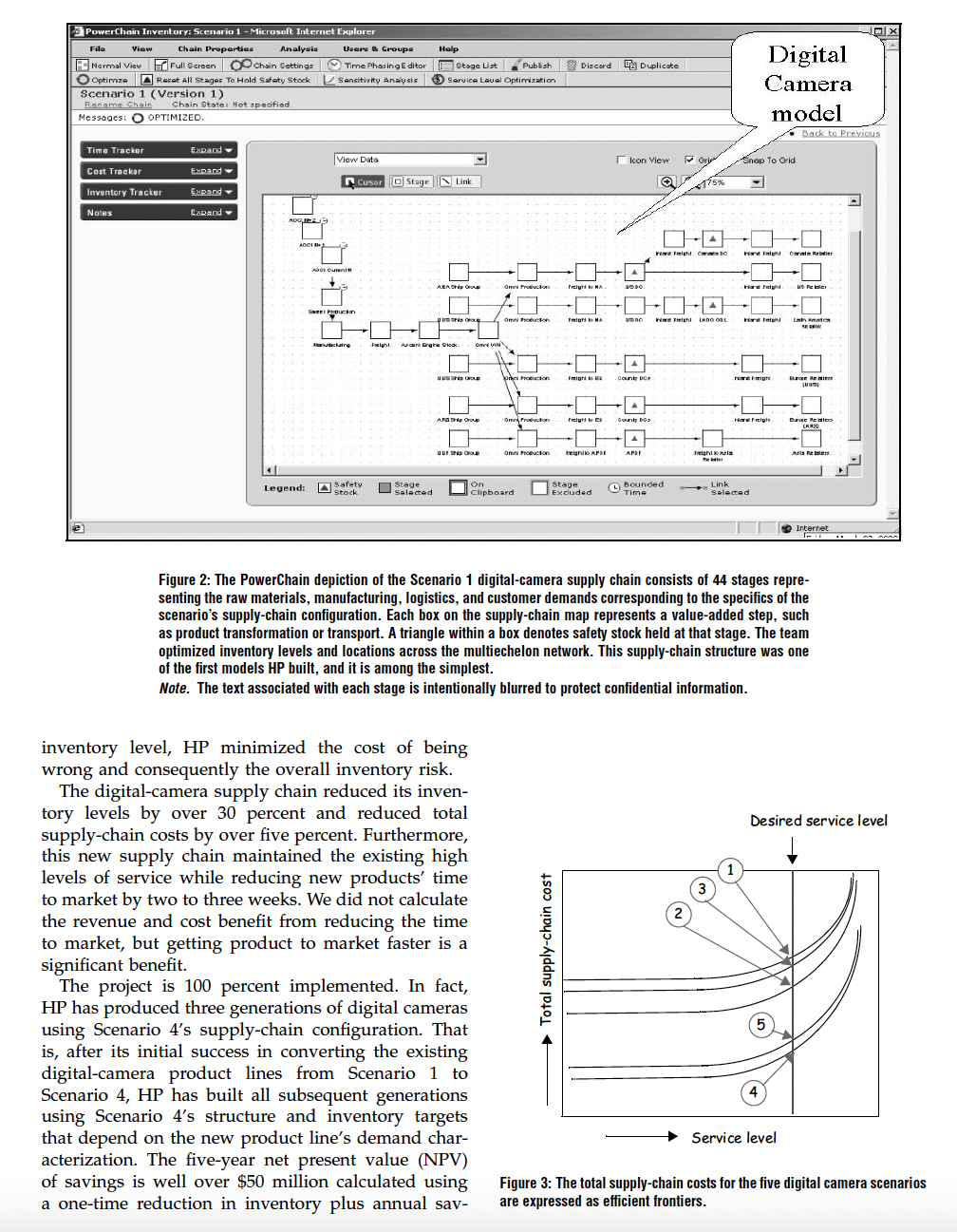

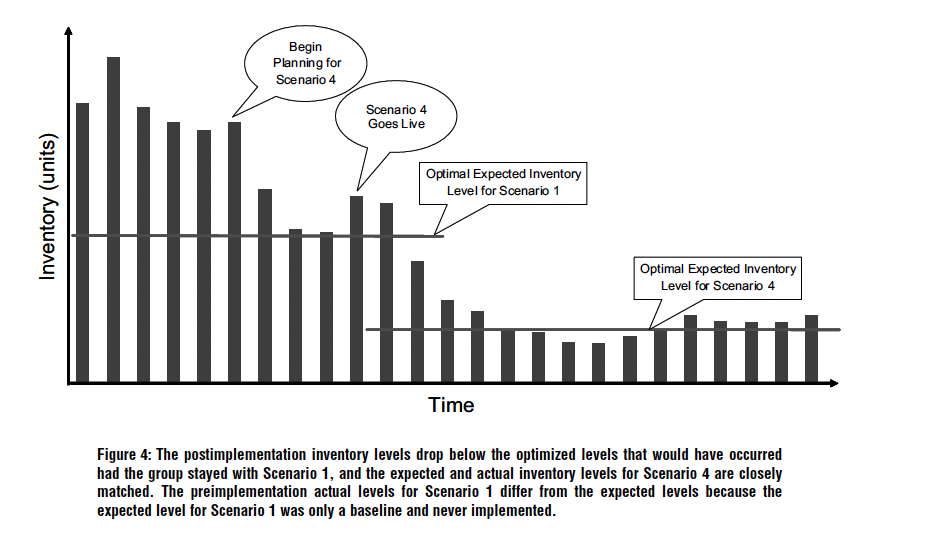

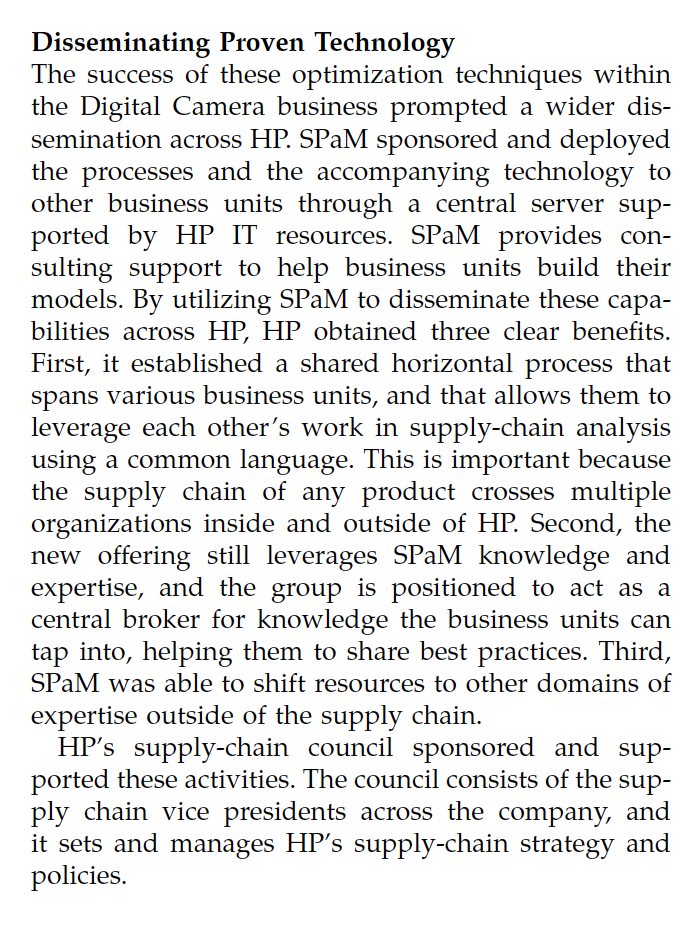

Optimizing the Digital Camera Business Digital imaging is a key growth area for HP. HP's Digital Imaging organization produces an array of imaging products. Consumer offerings include digital cameras, flatbed scanners, and photo inkjet printers. HP s commercial products include Phogenix photoprocessing equipment and Indigo digital presses. The Digital Imaging group develops complete imaging solutions for its customers, everything from image capture to image output, and all of the software and infrastructure connecting the two. HP entered the digital camera market in 1997 with a single camera. Today, it sells over half a dozen cameras, ranging from aggressively priced autofocus cameras to high-optical-zoom, high-megapixel products. The digital camera business is extremely competitive; HP competes with Canon, Kodak, Nikon, Olympus, and Sony. Product life cycles commonly run less than a year, with prices rapidly declining over this period. In the fall of 2000, the manufacturing manager for the digital camera organization asked his team to improve the performance of the digital-camera supply chain. Led by supply-chain engineers, this effort was supported by resources from finance, manufacturing engineering, research and development, and logistics. After considering various potential supplychain alternatives, the team identified five scenarios to analyze in depth (Figure 1). Scenario 1 was business as usual. In the existing supply chain, digital cameras went from a dedicated factory in Asia to a single worldwide hub, also in Asia. This hub localized the cameras (packaged individual items for regional consumption) and sent Manufacturing/production Localization Distribution/order fulfillment Figure 1: The five scenarios for digital camera supply-chain configurations considered various levels of consolidation and localization between worldwide manufacturing facilities, a worldwide localization hub, and several regional distribution centers. Figure 2: The PowerChain depiction of the Scenario 1 digital-camera supply chain consists of 44 stages representing the raw materials, manufacturing, logistics, and customer demands corresponding to the specifics of the scenario's supply-chain configuration. Each box on the supply-chain map represents a value-added step, such as product transformation or transport. A triangle within a box denotes safety stock held at that stage. The team optimized inventory levels and locations across the multiechelon network. This supply-chain structure was one of the first models HP built, and it is among the simplest. Note. The text associated with each stage is intentionally blurred to protect confidential information. inventory level, HP minimized the cost of being wrong and consequently the overall inventory risk. The digital-camera supply chain reduced its inventory levels by over 30 percent and reduced total supply-chain costs by over five percent. Furthermore, this new supply chain maintained the existing high levels of service while reducing new products' time to market by two to three weeks. We did not calculate the revenue and cost benefit from reducing the time to market, but getting product to market faster is a significant benefit. The project is 100 percent implemented. In fact, HP has produced three generations of digital cameras using Scenario 4's supply-chain configuration. That is, after its initial success in converting the existing digital-camera product lines from Scenario 1 to Scenario 4, HP has built all subsequent generations using Scenario 4's structure and inventory targets that depend on the new product line's demand characterization. The five-year net present value (NPV) of savings is well over $50 million calculated using a one-time reduction in inventory plus annual sav- Figure 3: The total supply-chain costs for the five digital camera scenarios are expressed as efficient frontiers. Figure 4: The postimplementation inventory levels drop below the optimized levels that would have occurred had the group stayed with Scenario 1, and the expected and actual inventory levels for Scenario 4 are closely matched. The preimplementation actual levels for Scenario 1 differ from the expected levels because the expected level for Scenario 1 was only a baseline and never implemented. Disseminating Proven Technology The success of these optimization techniques within the Digital Camera business prompted a wider dissemination across HP. SPaM sponsored and deployed the processes and the accompanying technology to other business units through a central server supported by HP IT resources. SPaM provides consulting support to help business units build their models. By utilizing SPaM to disseminate these capabilities across HP, HP obtained three clear benefits. First, it established a shared horizontal process that spans various business units, and that allows them to leverage each other's work in supply-chain analysis using a common language. This is important because the supply chain of any product crosses multiple organizations inside and outside of HP. Second, the new offering still leverages SPaM knowledge and expertise, and the group is positioned to act as a central broker for knowledge the business units can tap into, helping them to share best practices. Third, SPaM was able to shift resources to other domains of expertise outside of the supply chain. HP's supply-chain council sponsored and supported these activities. The council consists of the supply chain vice presidents across the company, and it sets and manages HP's supply-chain strategy and policies. Optimizing the Digital Camera Business Digital imaging is a key growth area for HP. HP's Digital Imaging organization produces an array of imaging products. Consumer offerings include digital cameras, flatbed scanners, and photo inkjet printers. HP s commercial products include Phogenix photoprocessing equipment and Indigo digital presses. The Digital Imaging group develops complete imaging solutions for its customers, everything from image capture to image output, and all of the software and infrastructure connecting the two. HP entered the digital camera market in 1997 with a single camera. Today, it sells over half a dozen cameras, ranging from aggressively priced autofocus cameras to high-optical-zoom, high-megapixel products. The digital camera business is extremely competitive; HP competes with Canon, Kodak, Nikon, Olympus, and Sony. Product life cycles commonly run less than a year, with prices rapidly declining over this period. In the fall of 2000, the manufacturing manager for the digital camera organization asked his team to improve the performance of the digital-camera supply chain. Led by supply-chain engineers, this effort was supported by resources from finance, manufacturing engineering, research and development, and logistics. After considering various potential supplychain alternatives, the team identified five scenarios to analyze in depth (Figure 1). Scenario 1 was business as usual. In the existing supply chain, digital cameras went from a dedicated factory in Asia to a single worldwide hub, also in Asia. This hub localized the cameras (packaged individual items for regional consumption) and sent Manufacturing/production Localization Distribution/order fulfillment Figure 1: The five scenarios for digital camera supply-chain configurations considered various levels of consolidation and localization between worldwide manufacturing facilities, a worldwide localization hub, and several regional distribution centers. Figure 2: The PowerChain depiction of the Scenario 1 digital-camera supply chain consists of 44 stages representing the raw materials, manufacturing, logistics, and customer demands corresponding to the specifics of the scenario's supply-chain configuration. Each box on the supply-chain map represents a value-added step, such as product transformation or transport. A triangle within a box denotes safety stock held at that stage. The team optimized inventory levels and locations across the multiechelon network. This supply-chain structure was one of the first models HP built, and it is among the simplest. Note. The text associated with each stage is intentionally blurred to protect confidential information. inventory level, HP minimized the cost of being wrong and consequently the overall inventory risk. The digital-camera supply chain reduced its inventory levels by over 30 percent and reduced total supply-chain costs by over five percent. Furthermore, this new supply chain maintained the existing high levels of service while reducing new products' time to market by two to three weeks. We did not calculate the revenue and cost benefit from reducing the time to market, but getting product to market faster is a significant benefit. The project is 100 percent implemented. In fact, HP has produced three generations of digital cameras using Scenario 4's supply-chain configuration. That is, after its initial success in converting the existing digital-camera product lines from Scenario 1 to Scenario 4, HP has built all subsequent generations using Scenario 4's structure and inventory targets that depend on the new product line's demand characterization. The five-year net present value (NPV) of savings is well over $50 million calculated using a one-time reduction in inventory plus annual sav- Figure 3: The total supply-chain costs for the five digital camera scenarios are expressed as efficient frontiers. Figure 4: The postimplementation inventory levels drop below the optimized levels that would have occurred had the group stayed with Scenario 1, and the expected and actual inventory levels for Scenario 4 are closely matched. The preimplementation actual levels for Scenario 1 differ from the expected levels because the expected level for Scenario 1 was only a baseline and never implemented. Disseminating Proven Technology The success of these optimization techniques within the Digital Camera business prompted a wider dissemination across HP. SPaM sponsored and deployed the processes and the accompanying technology to other business units through a central server supported by HP IT resources. SPaM provides consulting support to help business units build their models. By utilizing SPaM to disseminate these capabilities across HP, HP obtained three clear benefits. First, it established a shared horizontal process that spans various business units, and that allows them to leverage each other's work in supply-chain analysis using a common language. This is important because the supply chain of any product crosses multiple organizations inside and outside of HP. Second, the new offering still leverages SPaM knowledge and expertise, and the group is positioned to act as a central broker for knowledge the business units can tap into, helping them to share best practices. Third, SPaM was able to shift resources to other domains of expertise outside of the supply chain. HP's supply-chain council sponsored and supported these activities. The council consists of the supply chain vice presidents across the company, and it sets and manages HP's supply-chain strategy and policies

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts