Question: please help. I have attached the required information sheet Figure 3: Bolted joint application A pipeline is being designed and has a branch that will

please help. I have attached the required information sheet

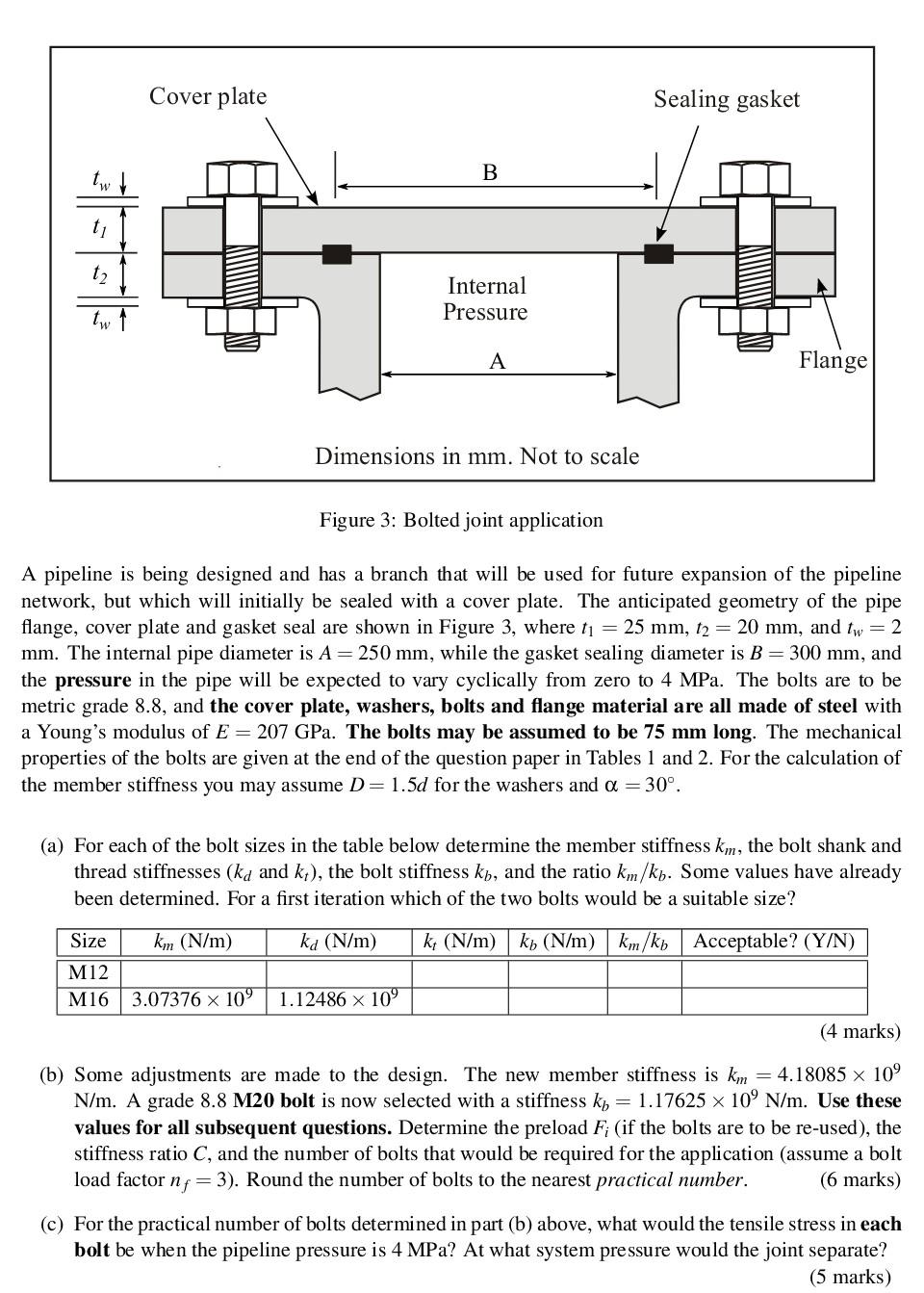

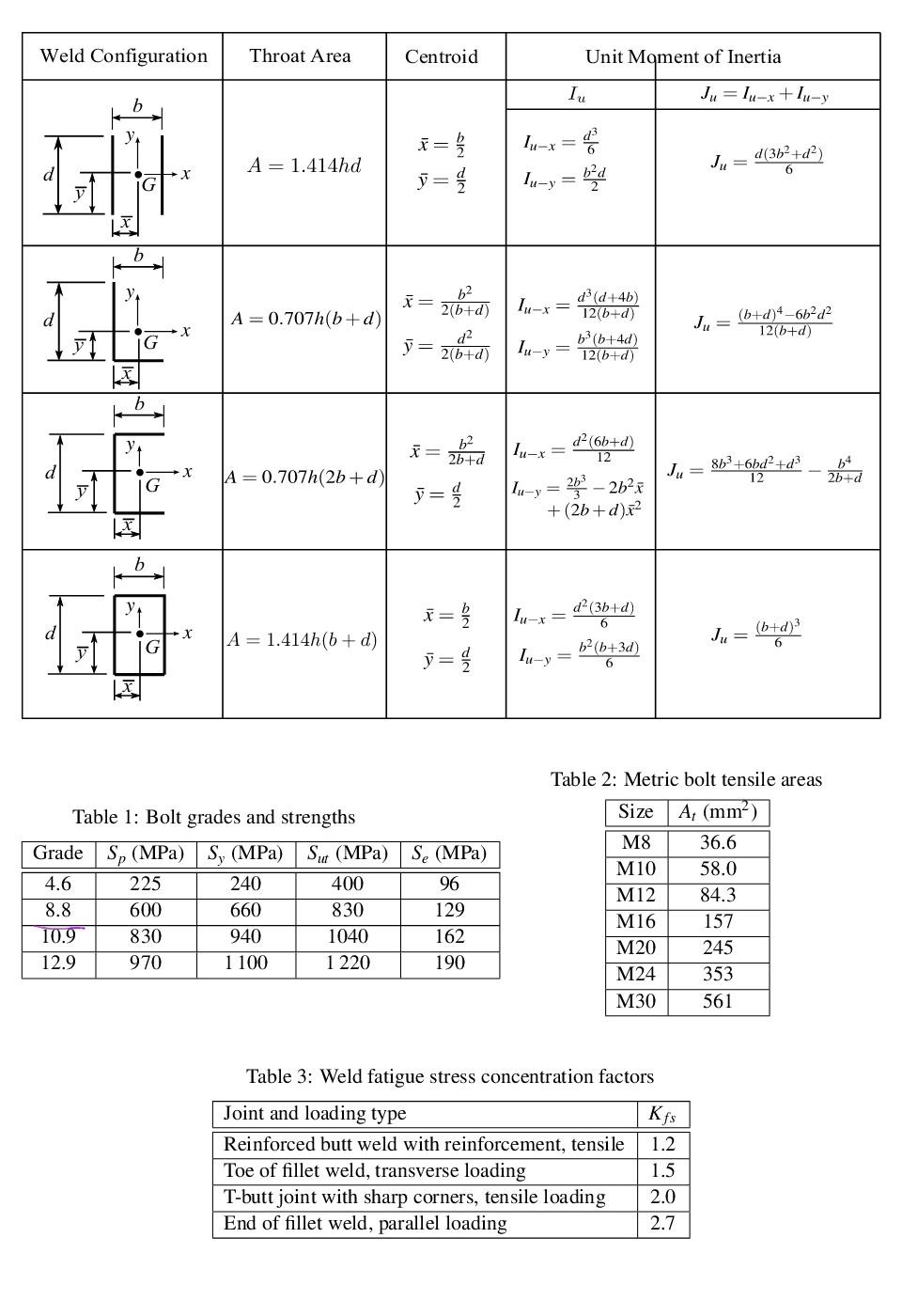

Figure 3: Bolted joint application A pipeline is being designed and has a branch that will be used for future expansion of the pipeline network, but which will initially be sealed with a cover plate. The anticipated geometry of the pipe flange, cover plate and gasket seal are shown in Figure 3, where t1=25mm,t2=20mm, and tw=2 mm. The internal pipe diameter is A=250mm, while the gasket sealing diameter is B=300mm, and the pressure in the pipe will be expected to vary cyclically from zero to 4MPa. The bolts are to be metric grade 8.8, and the cover plate, washers, bolts and flange material are all made of steel with a Young's modulus of E=207GPa. The bolts may be assumed to be 75mm long. The mechanical properties of the bolts are given at the end of the question paper in Tables 1 and 2. For the calculation of the member stiffness you may assume D=1.5d for the washers and =30. (a) For each of the bolt sizes in the table below determine the member stiffness km, the bolt shank and thread stiffnesses (kd and kt ), the bolt stiffness kb, and the ratio km/kb. Some values have already been determined. For a first iteration which of the two bolts would be a suitable size? (4 marks) (b) Some adjustments are made to the design. The new member stiffness is km=4.18085109 N/m. A grade 8.8M20 bolt is now selected with a stiffness kb=1.17625109N/m. Use these values for all subsequent questions. Determine the preload Fi (if the bolts are to be re-used), the stiffness ratio C, and the number of bolts that would be required for the application (assume a bolt load factor nf=3 ). Round the number of bolts to the nearest practical number. (6 marks) (c) For the practical number of bolts determined in part (b) above, what would the tensile stress in each bolt be when the pipeline pressure is 4MPa ? At what system pressure would the joint separate? (5 marks) Table 2: Metric bolt tensile areas Table 1: Bolt grades and strengths Table 3: Weld fatigue stress concentration factors

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts