Question: Please help me explain this step by step. Thank you so much. DuPage Powder Coating (LO4,5) DuPage Powder Coating applies powder coating finishes to a

Please help me explain this step by step. Thank you so much.

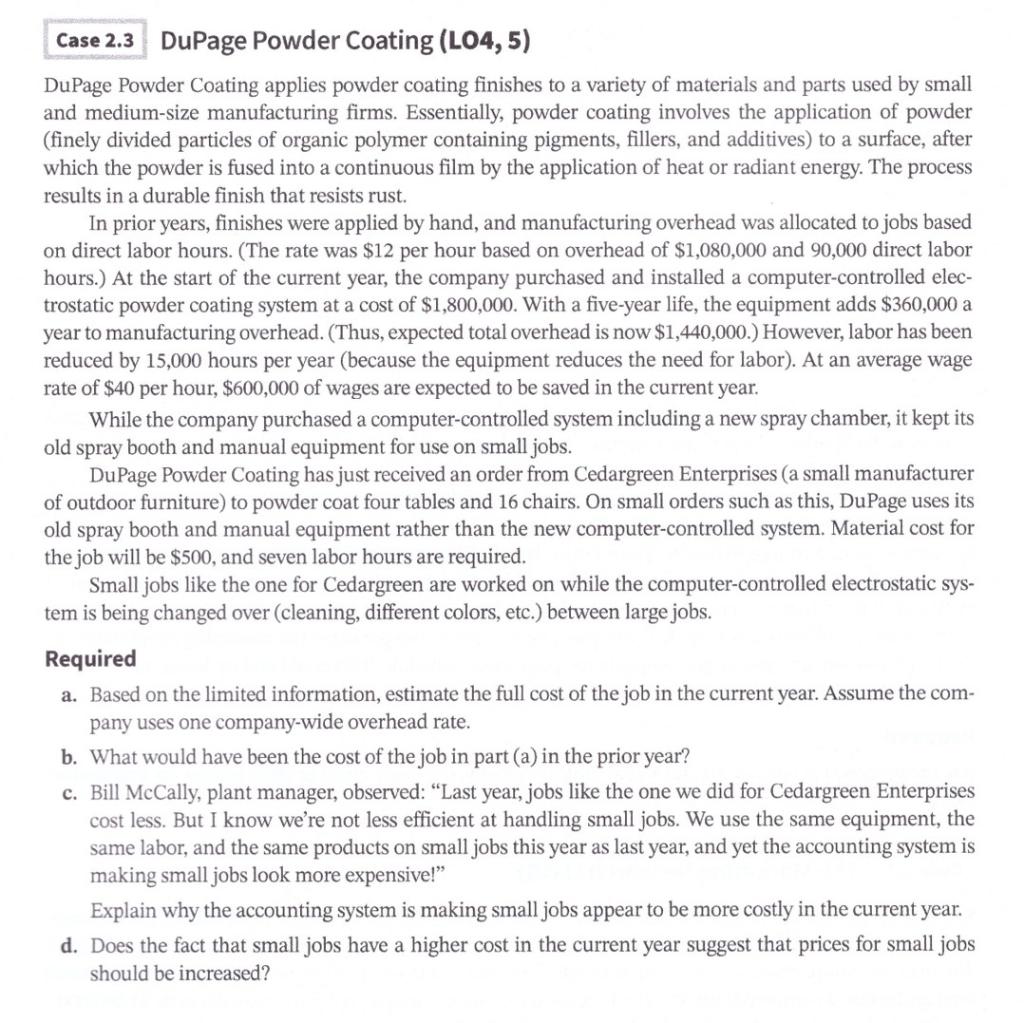

DuPage Powder Coating (LO4,5) DuPage Powder Coating applies powder coating finishes to a variety of materials and parts used by small and medium-size manufacturing firms. Essentially, powder coating involves the application of powder (finely divided particles of organic polymer containing pigments, fillers, and additives) to a surface, after which the powder is fused into a continuous film by the application of heat or radiant energy. The process results in a durable finish that resists rust. In prior years, finishes were applied by hand, and manufacturing overhead was allocated to jobs based on direct labor hours. (The rate was $12 per hour based on overhead of $1,080,000 and 90,000 direct labor hours.) At the start of the current year, the company purchased and installed a computer-controlled electrostatic powder coating system at a cost of $1,800,000. With a five-year life, the equipment adds $360,000 a year to manufacturing overhead. (Thus, expected total overhead is now $1,440,000.) However, labor has been reduced by 15,000 hours per year (because the equipment reduces the need for labor). At an average wage rate of $40 per hour, $600,000 of wages are expected to be saved in the current year. While the company purchased a computer-controlled system including a new spray chamber, it kept its old spray booth and manual equipment for use on small jobs. DuPage Powder Coating has just received an order from Cedargreen Enterprises (a small manufacturer of outdoor furniture) to powder coat four tables and 16 chairs. On small orders such as this, DuPage uses its old spray booth and manual equipment rather than the new computer-controlled system. Material cost for the job will be $500, and seven labor hours are required. Small jobs like the one for Cedargreen are worked on while the computer-controlled electrostatic system is being changed over (cleaning, different colors, etc.) between large jobs. Required a. Based on the limited information, estimate the full cost of the job in the current year. Assume the company uses one company-wide overhead rate. b. What would have been the cost of the job in part (a) in the prior year? c. Bill McCally, plant manager, observed: "Last year, jobs like the one we did for Cedargreen Enterprises cost less. But I know we're not less efficient at handling small jobs. We use the same equipment, the same labor, and the same products on small jobs this year as last year, and yet the accounting system is making small jobs look more expensive!" Explain why the accounting system is making small jobs appear to be more costly in the current year. d. Does the fact that small jobs have a higher cost in the current year suggest that prices for small jobs should be increased

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts