Question: Please help me, I am stuck with this problem. Please show your work in Excel and what formulas you used. Thank you Historical Demand for

Please help me, I am stuck with this problem. Please show your work in Excel and what formulas you used. Thank you

Please help me, I am stuck with this problem. Please show your work in Excel and what formulas you used. Thank you

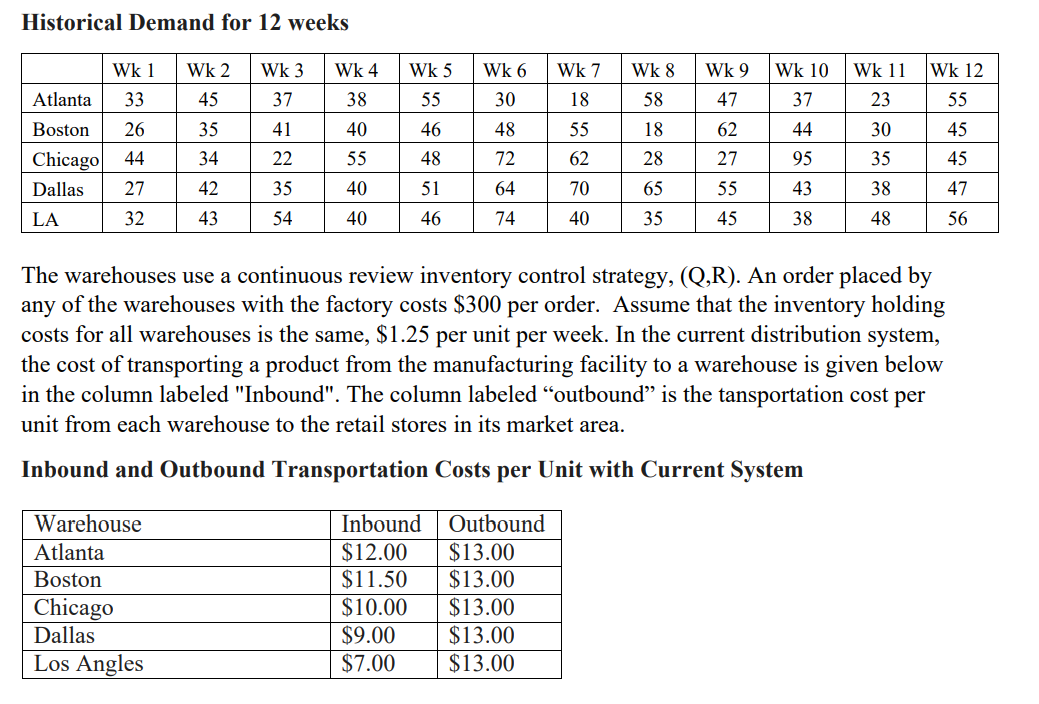

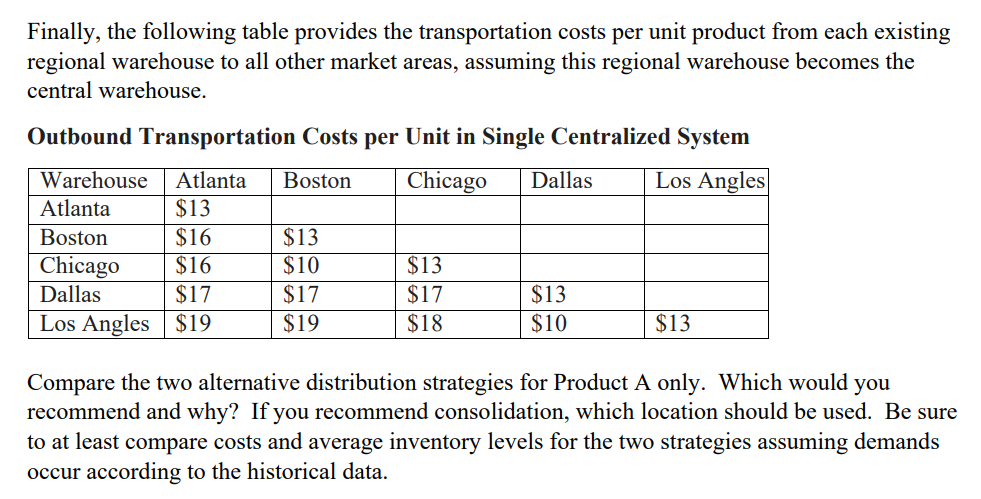

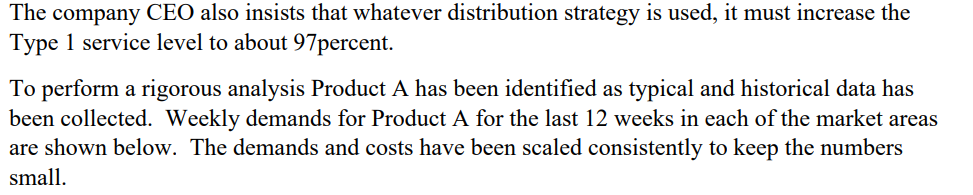

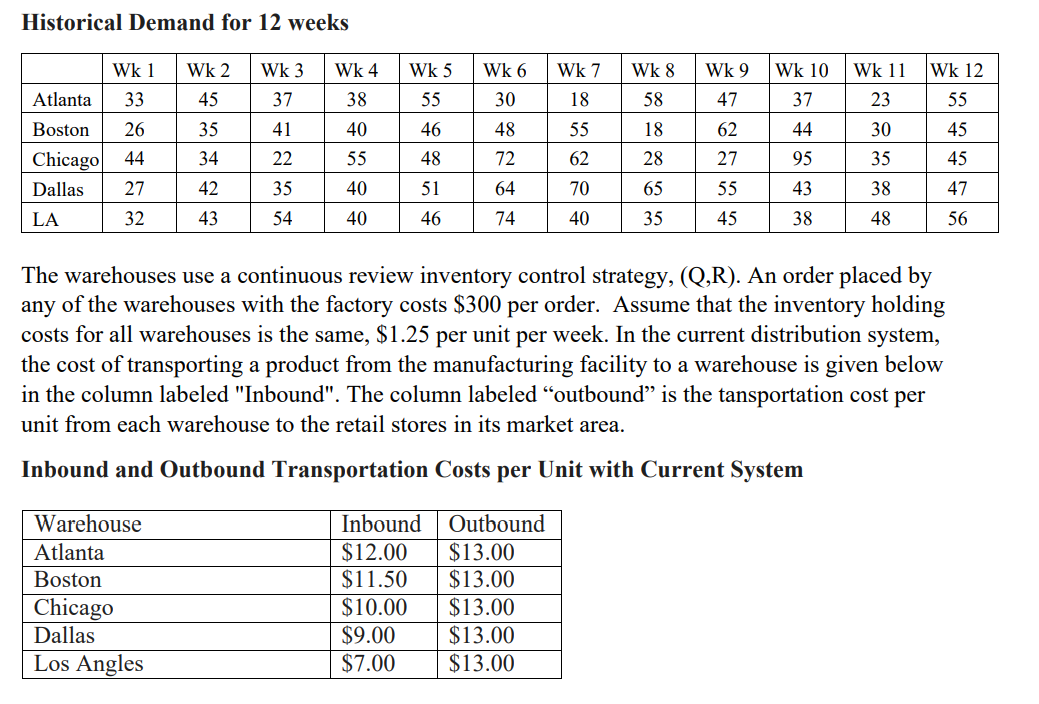

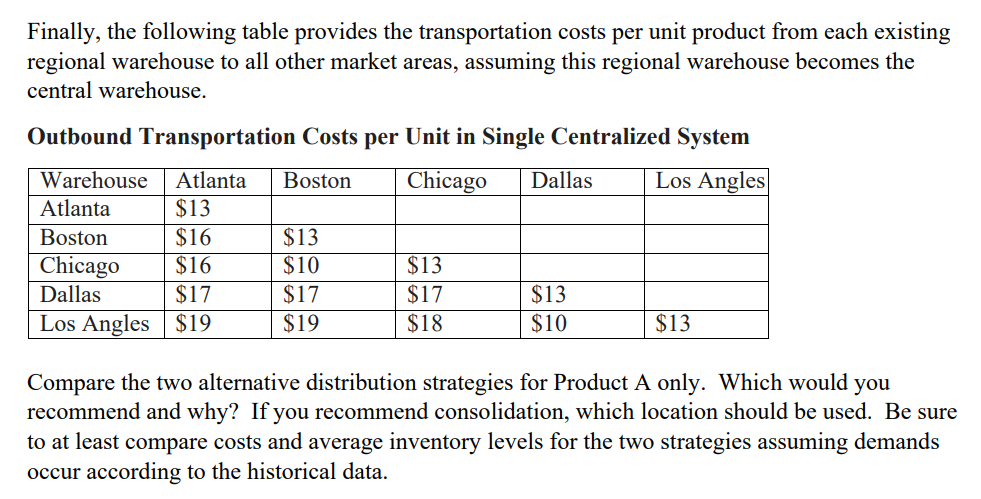

Historical Demand for 12 weeks The warehouses use a continuous review inventory control strategy, (Q,R). An order placed by any of the warehouses with the factory costs $300 per order. Assume that the inventory holding costs for all warehouses is the same, $1.25 per unit per week. In the current distribution system, the cost of transporting a product from the manufacturing facility to a warehouse is given below in the column labeled "Inbound". The column labeled "outbound" is the tansportation cost per unit from each warehouse to the retail stores in its market area. Inbound and Outbound Transportation Costs per Unit with Current System Finally, the following table provides the transportation costs per unit product from each existing regional warehouse to all other market areas, assuming this regional warehouse becomes the central warehouse. Outbound Transportation Costs per Unit in Single Centralized System Compare the two alternative distribution strategies for Product A only. Which would you recommend and why? If you recommend consolidation, which location should be used. Be sure to at least compare costs and average inventory levels for the two strategies assuming demands occur according to the historical data. The company CEO also insists that whatever distribution strategy is used, it must increase the Type 1 service level to about 97 percent. To perform a rigorous analysis Product A has been identified as typical and historical data has been collected. Weekly demands for Product A for the last 12 weeks in each of the market areas are shown below. The demands and costs have been scaled consistently to keep the numbers small. Historical Demand for 12 weeks The warehouses use a continuous review inventory control strategy, (Q,R). An order placed by any of the warehouses with the factory costs $300 per order. Assume that the inventory holding costs for all warehouses is the same, $1.25 per unit per week. In the current distribution system, the cost of transporting a product from the manufacturing facility to a warehouse is given below in the column labeled "Inbound". The column labeled "outbound" is the tansportation cost per unit from each warehouse to the retail stores in its market area. Inbound and Outbound Transportation Costs per Unit with Current System Finally, the following table provides the transportation costs per unit product from each existing regional warehouse to all other market areas, assuming this regional warehouse becomes the central warehouse. Outbound Transportation Costs per Unit in Single Centralized System Compare the two alternative distribution strategies for Product A only. Which would you recommend and why? If you recommend consolidation, which location should be used. Be sure to at least compare costs and average inventory levels for the two strategies assuming demands occur according to the historical data. The company CEO also insists that whatever distribution strategy is used, it must increase the Type 1 service level to about 97 percent. To perform a rigorous analysis Product A has been identified as typical and historical data has been collected. Weekly demands for Product A for the last 12 weeks in each of the market areas are shown below. The demands and costs have been scaled consistently to keep the numbers small

Please help me, I am stuck with this problem. Please show your work in Excel and what formulas you used. Thank you

Please help me, I am stuck with this problem. Please show your work in Excel and what formulas you used. Thank you