Question: please help me out with this problem and please explain in details so, that I understand thank you!! 3. (2 pts) You are working for

please help me out with this problem and please explain in details so, that I understand thank you!!

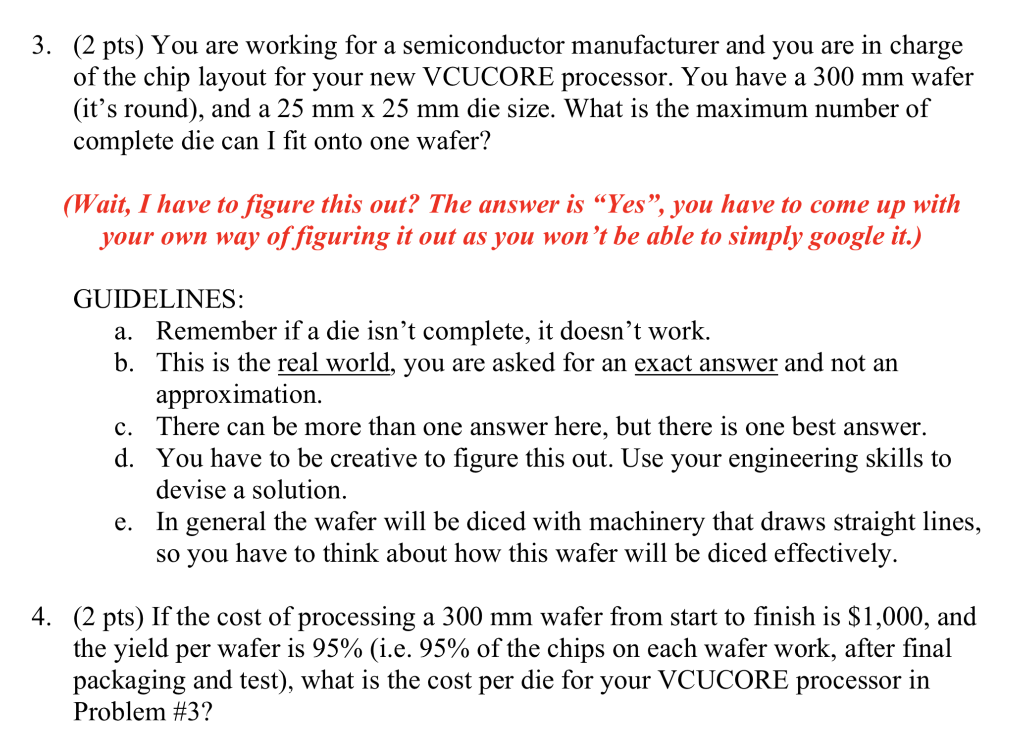

3. (2 pts) You are working for a semiconductor manufacturer and you are in charge of the chip layout for your new VCUCORE processor. You have a 300 mm wafer (it's round), and a 25 mm x 25 mm die size. What is the maximum number of complete die can I fit onto one wafer? (Wait, I have to figure this out? The answer is Yes, you have to come up with your own way of figuring it out as you won't be able to simply google it.) a. GUIDELINES: Remember if a die isn't complete, it doesn't work. b. This is the real world, you are asked for an exact answer and not an approximation. c. There can be more than one answer here, but there is one best answer. d. You have to be creative to figure this out. Use your engineering skills to devise a solution. e. In general the wafer will be diced with machinery that draws straight lines, so you have to think about how this wafer will be diced effectively. 4. (2 pts) If the cost of processing a 300 mm wafer from start to finish is $1,000, and the yield per wafer is 95% (i.e. 95% of the chips on each wafer work, after final packaging and test), what is the cost per die for your VCUCORE processor in Problem #3? 3. (2 pts) You are working for a semiconductor manufacturer and you are in charge of the chip layout for your new VCUCORE processor. You have a 300 mm wafer (it's round), and a 25 mm x 25 mm die size. What is the maximum number of complete die can I fit onto one wafer? (Wait, I have to figure this out? The answer is Yes, you have to come up with your own way of figuring it out as you won't be able to simply google it.) a. GUIDELINES: Remember if a die isn't complete, it doesn't work. b. This is the real world, you are asked for an exact answer and not an approximation. c. There can be more than one answer here, but there is one best answer. d. You have to be creative to figure this out. Use your engineering skills to devise a solution. e. In general the wafer will be diced with machinery that draws straight lines, so you have to think about how this wafer will be diced effectively. 4. (2 pts) If the cost of processing a 300 mm wafer from start to finish is $1,000, and the yield per wafer is 95% (i.e. 95% of the chips on each wafer work, after final packaging and test), what is the cost per die for your VCUCORE processor in Problem #3

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts