Question: Please help me solve this questions with workings and solutions. Thank you 3. (24+8) For the testing of new product, a certain mechanical assembly sequence

Please help me solve this questions with workings and solutions. Thank you

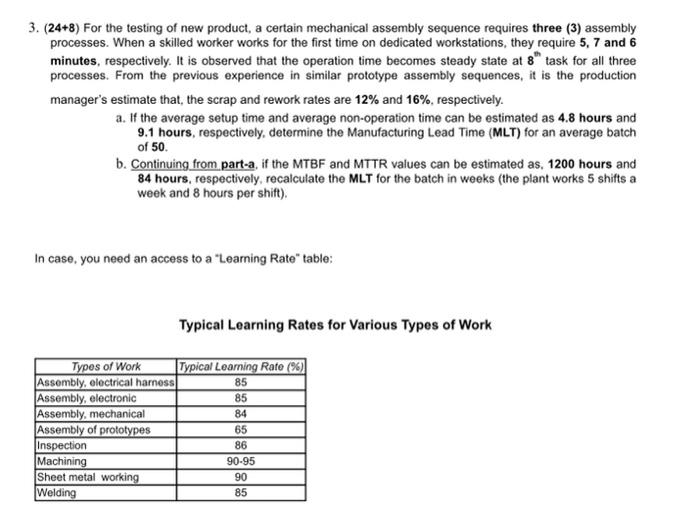

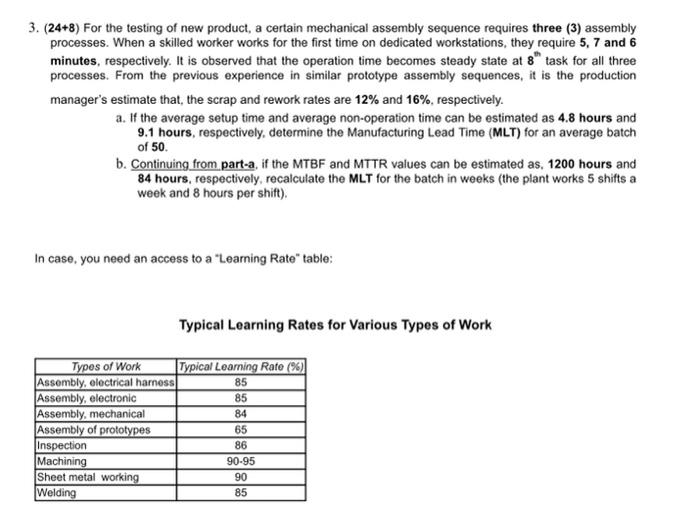

3. (24+8) For the testing of new product, a certain mechanical assembly sequence requires three (3) assembly processes. When a skilled worker works for the first time on dedicated workstations, they require 5,7 and 6 minutes, respectively. It is observed that the operation time becomes steady state at 8mp task for all three processes. From the previous experience in similar prototype assembly sequences, it is the production manager's estimate that, the scrap and rework rates are 12% and 16%, respectively. a. If the average setup time and average non-operation time can be estimated as 4.8 hours and 9.1 hours, respectively, determine the Manufacturing Lead Time (MLT) for an average batch of 50. b. Continuing from part-a, if the MTBF and MTTR values can be estimated as, 1200 hours and 84 hours, respectively, recalculate the MLT for the batch in weeks (the plant works 5 shifts a week and 8 hours per shift). In case, you need an access to a "Leaming Rate" table: Typical Learning Rates for Various Types of Work 3. (24+8) For the testing of new product, a certain mechanical assembly sequence requires three (3) assembly processes. When a skilled worker works for the first time on dedicated workstations, they require 5,7 and 6 minutes, respectively. It is observed that the operation time becomes steady state at 8mp task for all three processes. From the previous experience in similar prototype assembly sequences, it is the production manager's estimate that, the scrap and rework rates are 12% and 16%, respectively. a. If the average setup time and average non-operation time can be estimated as 4.8 hours and 9.1 hours, respectively, determine the Manufacturing Lead Time (MLT) for an average batch of 50. b. Continuing from part-a, if the MTBF and MTTR values can be estimated as, 1200 hours and 84 hours, respectively, recalculate the MLT for the batch in weeks (the plant works 5 shifts a week and 8 hours per shift). In case, you need an access to a "Leaming Rate" table: Typical Learning Rates for Various Types of Work

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock